Edm Graphite Electrode for Electric Arc Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite Electrode for Electric Arc Furnace

Composite of Graphite Electrode for Electric Arc Furnace:

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke

and widely used in the electric arc furnaces for production of alloy steels, metal and other

nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm.

Applications of Graphite Electrode for Electric Arc Furnace:

It is used for the electric arc furnace steel making. (About 70-80% graphite electrode is used for steel making).

It is used for the submerged arc furnace, including melting iron alloy, pure silicon, yellow

phosphorus,matte, calcium carbide and so on.

It is used for the resistance furnace, such as the graphite making, melting glass, silicon carbide

making and so on.

Advantages of Graphite Electrode for Electric Arc Furnace:

low electric resistance

good electric and thermal conductivity

high oxidation resistance

high mechanical strength

high machining accuracy

greater resistance to thermal and mechanical shock

28 drums counter-flow calcining furnace

Auto-control dosing system

Germany Enrich kneading system

3500MT vertical tamping&horizontal extruding press

Auto-comtrol ring backing furnace

Germany Feist-incon 2nd Baking Kiln

High pressure imprgnation system

Acheson high power DC graphitizing furnace

Japan Nachi NC electrode machining line

America lngersoll NC electrode machine line

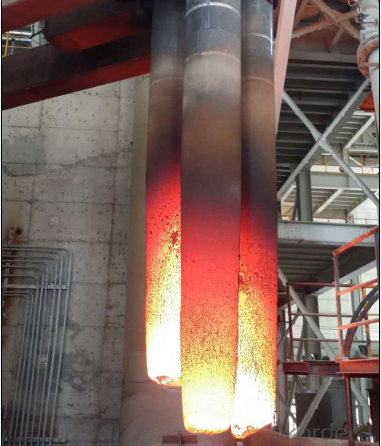

Graphite Electrode for Electric Arc Furnace Images

Specifications of Graphite Electrode for Electric Arc Furnace:

Item | Unit | Regular-power | Impregnated | ||||||

φ75- | φ150- | φ250- | φ350- | φ75- | φ250- | φ400- | |||

130 | 225 | 300 | 500 | 200 | 350 | 500 | |||

Specific Resistance (≤) | E | μ Ω·m | 8.5 | 9 | 9 | 9 | 8 | 8 | 8 |

N | 8 | 8 | 8 | 8 | 7.5 | 7.5 | 7.5 | ||

Bending Strength (≥) | E | MPa | 9.8 | 9.8 | 7.8 | 6.4 | 10 | 9 | 8 |

N | 13 | 13 | 13 | 13 | 15 | 15 | 15 | ||

Elastic Modulus (≤) | E | GPa | 9.3 | 9.3 | 9.3 | 9.3 | 12 | 12 | 12 |

N | 14 | 14 | 14 | 14 | 14 | 14 | 14 | ||

Bulk Density (≥) | E | g/cm3 | 1.58 | 1.52 | 1.52 | 1.52 | 1.58 | 1.58 | 1.58 |

N | 1.63 | 1.63 | 1.68 | 1.68 | 1.68 | 1.68 | 1.68 | ||

C.T.E.(≤) | E | 10-6/°C | 2.9 | 2.9 | 2.9 | 2.9 | 2.7 | 2.7 | 2.7 |

(100-600°C) | |||||||||

| N | 2.7 | 2.7 | 2.8 | 2.8 | 2.5 | 2.5 | 2.5 | |

Ash(≤) |

| % | 0.5 | 0.5 | 0.5 | 0.5 | 0.3 | 0.3 | 0.3 |

FAQ of Graphite Electrode for Electric Arc Furnace

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services for you!!

- Q: What is the striking electrode in the die making? Where is the technical point?

- Electrical discharge machining (EDM) is a spark discharge in a liquid medium at a lower voltage range to meet the required shape and size.

- Q: What is the difference between pyridine type nitrogen and graphite type nitrogen?

- In fact, this problem is very simple, the carbon graphite is six square lattice ordered, natural graphite and artificial graphite is divided into two kinds: the classification of natural graphite flake graphite and graphite is earthy, basically it is not forming soil shaped graphite graphite, are rough machining, the battery core and do more. The use ratio of flake graphite.

- Q: Is graphite flammable?Why do I bake pencil cores with a fever that doesn't burn?

- In anaerobic conditions, the ignition temperature is at least above 3000 degrees. There are many types of graphite, different types of ignition points, and the burning point of pyrolytic graphite...

- Q: Electrolytic salt water why use iron as a cathode, all with graphite can not?

- From an economic point of view, the storage amount of iron is much larger than that of graphite, graphite iron is cheaper and easier to get.

- Q: Is the anode of electrolytic water suitable for ordinary titanium wires?

- The graphite is cheaper and easier to obtain, but the carbon electrodes sold in the general market are not very pure at most times. The experiment is done for a period of time, and the carbon is inexplicably broken, especially if you need to work for a long time. So, if your graphite electrode is of good quality, it's still graphite.

- Q: What's the use of carbon?

- Oxidation resistant coating graphite electrode. A graphite electrode coated with an antioxidant protective layer is applied to form a protective layer that is conductive and resistant to oxidation at high temperature, thereby reducing electrode consumption during steelmaking.

- Q: Please senior doubts. The graphite electrode is used in the mold cavity In what case is graphite processing taken?

- Because of the great loss of graphite electrode in finishing, it is not suitable to be used as finishing electrode material. Because of the small coefficient of thermal expansion of graphite, it can also be used as a big electrode material in perforation processing.

- Q: Classification of graphite electrodes

- Allows the use of current density of less than 17A/ cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, yellow phosphorus and other ordinary power furnace.

- Q: Graphite graphite graphite graphite electrode what is the use?

- Electrode graphite powder that can be used for the production of electrodes, because the conductive properties of graphite electrode, so that the electrode graphite powder can become conductive graphite powder, graphite powder can also be applied to the field of conductive or conductive composite materials production.

- Q: What do carbon products include?

- Carbon products can be divided into graphite electrode, carbon block, graphite anode, carbon electrode, paste, electric carbon, carbon fiber, special graphite, graphite heat exchanger and so on according to the use of products. Graphite electrode class can be divided into ordinary power graphite electrode according to the allowable current density.

Send your message to us

Edm Graphite Electrode for Electric Arc Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords