Immersive Engineering Graphite Electrode for Arc Furnace/EDM

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm. Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

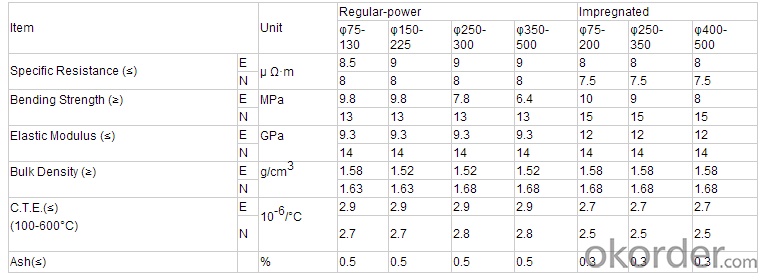

Graphite Electrodes Specifications

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

Technical data:

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What is the difference between pyridine type nitrogen and graphite type nitrogen?

- The fine structure graphite is the raw material used in the production of graphite electrode. The particle size is relatively small, generally below 0.5.

- Q: The future of graphene

- Energy storage and new display areas. Graphene has excellent conductivity and transparency. As a transparent conductive electrode material, graphene has a good application in touch screen, liquid crystal display, energy storage batteries and so on. Graphene is considered to be the most potential alternative to indium tin oxide manufacturing in touch screen manufacturing, and Samsung, SONY, Hui Rui, 3M, Dongli, Toshiba and other leading enterprises have made key research and development layout in this field. Researchers at the University of Dezhou, Austen, used KOH to chemically modify graphene to form a porous structure, resulting in a storage density of ultracapacitor near the lead acid battery. Michigan Technological University scientists have developed a unique honeycomb structure of three-dimensional graphene electrode, photoelectric conversion efficiency of 7.8%, and low price, is expected to replace platinum in solar cells applications. Toshiba Co developed graphene and silver nanowires composite transparent electrode, and achieved a large area.

- Q: Specification for graphite electrodes commonly used in steel works

- In general, the graphite electrode used in steelmaking furnace is mostly made of ordinary power and high power graphite electrode. Now, the use of ultra high power graphite electrode increases year by year, accounting for almost half of the graphite electrode.

- Q: Please senior doubts. The graphite electrode is used in the mold cavity In what case is graphite processing taken?

- Because of the great loss of graphite electrode in finishing, it is not suitable to be used as finishing electrode material. Because of the small coefficient of thermal expansion of graphite, it can also be used as a big electrode material in perforation processing.

- Q: The production of one ton of steel required graphite electrode

- Can not generally say, a ton of steel production consumes much of graphite electrode.

- Q: The graphite electrode made by the machining center adopts cooling method, which is water cooled, oil cooled and blow cold. Which is good?

- In addition, the infiltration of water on graphite is not good, can not get the effect of dust removal. Now there are special graphite machine, sealing system. Air-cooled can be used, after all, the best air-cooled.

- Q: Do electroplating experiments, graphite as an electrode, graphite how to pre process to ensure that the coating will not fall, resulting in increased color of the solution

- Graphite as anode, generally do not need special treatment, but to choose high purity, high density, high strength (so-called "three high" graphite) graphite on the line, this graphite in brush plating operations are often used as anode material.

- Q: How can the graphite powder be processed into high quality carburizing agent? Thank you

- Basically, it can no longer be a "good" carburizing agent

- Q: Why is graphite a negative pole and copper is an anode?

- Electrolysis (Electrolysis) is the current through the electrolyte solution or molten electrolyte (also called electrolyte), caused by the redox reaction in the cathode and the anode, the electrochemical cell can occur when an external DC voltage in the electrolysis process.

- Q: 800KVA and 12500 EAF transformer data graphite electrode furnace.

- Graphite project: Project Description: steel furnace and iron smelting furnace, ferrosilicon smelting, electrolytic aluminum and so on, all use large surface graphite electrode.

Send your message to us

Immersive Engineering Graphite Electrode for Arc Furnace/EDM

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords