Graphite Electrode for Arc Furnaces/HP Electrode Graphites

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Graphite Electrodes

.Grade:RP,HP,UHP,SHP,RPI

.Diameter:200 to 700mm at your choice.

.Length: 1600 to 2400mm at your choice.

.Nipple:3-4 TPI

.fine mechanical strength and machining quality,low specific resistance, high temperature and oxidation resistance

2. Applications of Graphite Electrodes

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

3. Grades: RP, RPI, HP, SHP, UHP

Details Information | ||||||||

Items | Unit | RP | HP | UHP | ||||

250-300mm | 350-550mm | 200-400mm | 450-550mm | 300-400mm | 450-550mm | |||

Resistivity(MAX) | Electrode | μΩm | 9 | 7 | 7.5 | 6.2 | 6.5 | |

Nipple | 8.5 | 6.5 | 5.5 | |||||

Bending Strenth(MIN) | Electrode | Mpa | 7.8 | 6.4 | 10.5 | 9.8 | 10.5 | 10 |

Nipple | 13 | 14 | 16 | |||||

Elastic Modulus(MAX) | Electrode | Gpa | 9.3 | 12 | 14 | |||

Nipple | 14 | 16 | 18 | |||||

Bulk Density(MIN) | Electrode | g/cm3 | 1.52 | 1.6 | 1.65 | 1.64 | ||

Nipple | 1.68 | 1.7 | 1.72 | 1.7 | ||||

Ash(MAX) | Electrode/Nipple | % | 0.5 | 0.3 | 0.3 | |||

CTE(MAX) | Electrode | 10-6/°C | 2.9 | 2.4 | 1.5 | |||

Nipple | 2.8 | 2.2 | 1.4 | |||||

Tolerances of electrode diameters and lengthes(mm) | ||||

Nominal Diameter | Actual Diameter | Length | ||

Max | Min | Black surface min | ||

250 | 256 | 251 | 248 | 1600/1800 |

300 | 307 | 302 | 299 | 1600/1800 |

350 | 357 | 352 | 349 | 1600/1800 |

400 | 409 | 403 | 400 | 1600/1800/2000/2200 |

450 | 460 | 454 | 451 | 1600/1800/2000/2200 |

500 | 511 | 505 | 502 | 1800/2000/2200/2400 |

550 | 562 | 556 | 553 | 1800/2000/2200/2400 |

Recommended current carrying capacity | ||||||||||||

Nominal diameter | RP | HP | UHP | |||||||||

Electrical Arc furnace | Electrical Arc furnace | Ladle Refining furnace | Electrical Arc furnace | Ladle Refining furnace | ||||||||

Current carrying capacity | Current Density | Current carrying capacity | Current Density | Current carrying capacity | Current Density | Current carrying capacity | Current Density | Current carrying capacity | Current Density | |||

Inch | Mm | A | A/ cm2 | A | A/ cm2 | A | A/ cm2 | A | A/ cm2 | A | A/ cm2 | |

12 | 300 | 11000-15000 | 15-21 | 13000-17500 | 18-25 | 15000-21000 | 21-29 | |||||

14 | 350 | 15000-20000 | 15-20 | 17500-24500 | 18-25 | 20000-28000 | 21-29 | 22000-31000 | 23-32 | 24000-33000 | 25-34 | |

16 | 400 | 19000-26000 | 15-20 | 21500-32000 | 17-25 | 24000-35000 | 19-28 | 28000-41000 | 22-32 | 31000-44000 | 24-34 | |

18 | 450 | 23000-31000 | 14-19 | 26000-40500 | 16-25 | 29000-45000 | 18-28 | 33000-46000 | 20-28 | 36000-49000 | 22-30 | |

20 | 500 | 28000-36000 | 14-18 | 32000-50000 | 16-25 | 34000-54000 | 17-27 | 38000-56000 | 19-28 | 42000-60000 | 21-30 | |

22 | 550 | 32000-42000 | 37000-57000 | 15-23 | 40000-62000 | 16-25 | 45000-65000 | 18-26 | 50000-70000 | 20-28 | ||

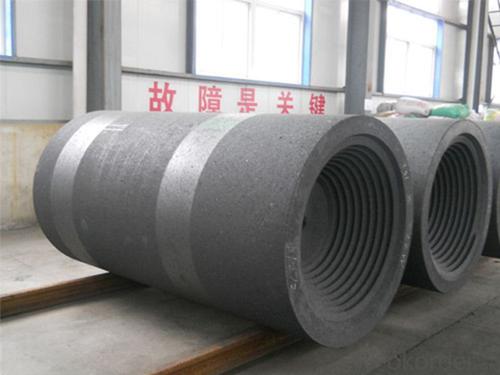

4. Pictures of Graphite Electrodes Factory

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty of Graphite Electrode for Arc Furnaces?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products Graphite Electrode for Arc Furnaces?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. We have D&B report and you could check details information for our company.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Why use platinum ferroalloy instead of iron as electrode?

- General industrial grade silicon dioxide, because the preparation technology is different, can be divided into two types, one is dry, sintered (Fume Type), a wet precipitation type (Precipitated Type), and two of the surface area, the surface with hydroxyl (-OH) are the same, in general, the former the latter is more, less, the two surface has the tendency of hydrophilic, as for lipophilic polymer, such as paint, rubber... Etc.,... If the silica surface pre rendered hydrophobic, has a good effect.

- Q: How to solve the problem of graphite electrode being crushed during electrolysis

- This graphite electrode is so true because it causes gas to expand and disintegrateTantalum electrodes can be solved and not expensive

- Q: After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- Negative poleThe color becomes lighter (the copper ion gets electrons in the cathode and becomes copper)

- Q: Does the silicon carbide heat plant require a fine structure graphite electrode? What kind of graphite products do you need?

- Silicon carbide graphite is very famous for its high hardness and wear resistance. It is generally used in high wear resistance machinery industry and high wear resistant sealing industry.

- Q: Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- Not alwaysIt depends on the rate of electrolyzed water or the rate at which sodium sulfite is oxidized.

- Q: What are the structures of pyrolytic graphite electrodes? What are their properties and applications? We hope that some details will not be found

- The high purity graphite component is put into the furnace, and nitrogen and methane are produced under vacuum high temperature. Then graphite is shown to produce 10% coating.

- Q: Are graphite and carbon electrodes the same? What kinds of ore furnaces are used?

- The main components of carbon electrodes are graphite, carbon powder and other impurities which are not converted into graphite. The resistivity is higher than that of graphite electrode. These electrodes are mostly used in electric furnace steelmaking, smelting aluminium oxide and other electric arc furnaces.

- Q: How can hydrogen be produced by electrolysis of sodium hydroxide with graphite as an electrode?

- Molten sodium hydroxide is ionized out of Na+ and OH-, electrons are lost at the anode OH-, oxygen and water are produced (immediately evaporated at high temperature), and electrons are generated at Na+ at the cathode Na

- Q: How should carbon deposits be treated?

- It is very necessary to clean the throttle valve, clean the nozzle, and clean the carbon in the engine cylinder! However, in order to reduce the trouble of cleaning, it is best to join the regular application of graphene Moqi additive in lubricating oil for engine.

- Q: Graphitized coke, graphite, broken, mixed up, how to export?

- Graphite electrode pieces in different data definition of graphite scrap is different, some data and literature of the graphite particles are called not great pieces of graphite (such as graphite) and some say that graphite products have a certain size, into a block of graphite broken, we are here to say Shi Mosui is second, often called as the graphite block. The production of graphite from graphite products, graphitization and machining process. Graphite waste used as an additive and as a conductive material in the steelmaking and casting industries.

Send your message to us

Graphite Electrode for Arc Furnaces/HP Electrode Graphites

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords