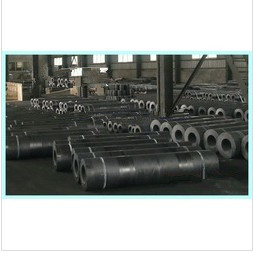

UHP Graphite Electrode Plate (Dia250-800mm)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Tons m.t.

- Supply Capability:

- 1000 Tons per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

- Model Number: Ultra High Power

- Type: Electrode Block

- Application: used in EAF/LF for steel making

- Diameter: 250mm-800mm

- Length: 1200mm-2400mm

- Grade: UHP (Ultra High Power)

- Resistance (μΩ.m): ≤5.5

- Apparent Density (g/cm³ ): ≥1.66

- Thermal Expansion: ≤1.5

- Flexural Strength (N/㎡): ≥11

- Elastic Modulus: ≤14

- Ash: ≤0.3

Specifications

Technical Specification UHP

|

Item |

Unit |

Nominal Diameter (mm) | ||

|

UHP | ||||

|

≤Φ400 |

≥Φ450 | |||

|

Resistance |

Electrode |

μΩ·m |

≤5.5 | |

|

Nipple |

≤4.5 | |||

|

Bending Strength |

Electrode |

MPa |

≥11.0 | |

|

Nipple |

≥20.0 | |||

|

Elastic Modulus |

Electrode |

GPa |

≤14.0 | |

|

Nipple |

≤18.0 | |||

|

Bulk Density |

Electrode |

g/cm3 |

≥1.66 |

≥1.67 |

|

Nipple |

≥1.75 | |||

|

C.T.E. |

Electrode |

10-6/°C |

≤1.5 | |

|

Nipple |

≤1.4 | |||

|

Ash |

% |

≤0.3 | ||

- Q: The future of graphene

- Sensor domain. Graphene due to its unique two-dimensional structure is widely used in sensor, has the advantages of small size, large surface area, high sensitivity, fast response time, fast and easy electron transfer protein immobilization and maintained its activity and other characteristics, can improve the performance of sensor. Mainly used in the production of gas, biological molecules, enzymes and DNA electrochemical sensors. Singapore Nanyang Technology University developed a graphene light sensor sensitivity is 1000 times the ordinary sensor; the Rensselaer Polytechnic Institute developed performance than the existing commercial gas sensor cheap graphene sponge sensor.

- Q: The use of graphite as an electrode in alumina electrolysis

- Graphite acts as an electrode:The electrical conductivity of graphite, the electrode itself must be electrically conductive;When graphite acts as an anode, it acts as a reducing agent and displaces an element of aluminum in a chemical reaction;Graphite is cheap and cost saving.

- Q: Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- Can't。 During electrolysis, there is depletion of sulfite ions.

- Q: In EDM, the electrodes are made of graphite and copper. Please tell us the difference between them

- For the mold finishing, most of the time are red copper click, low loss, high precision, of course, higher precision, or requirements of copper tungsten alloy electrodes are also available

- Q: Can graphite be used as an electrode for electrolysis of silver in silver nitrate?

- Xiaoyi Liyang said the principle is correct, but can get silver? I think we can solve the problem if we take proper measures to get the silver elements, such as separating the anode and the cathode from the salt water!

- Q: Graphite powder produced by graphite electrode and what we usually call graphite is a kind of thing?

- Graphite electrode is mainly in petroleum coke, coke as raw material

- Q: What's the purpose of the electrode material?When the electrolytic molten state of NaCl is said, what is the use of the graphite electrode and the iron electrode?

- 1. graphite (two kinds of EDM3 and EDM200)2. copperIn general, graphite electrode for extensive escape material (graphite texture loose, discharge energy is relatively large, removal of materials faster, but face flowers that roughness is relatively large

- Q: What are the losses in graphite electrode?

- So tell, this problem is to answer a lot, graphite under high temperature oxidation, generally around 400 degrees, began a slight oxidation, but the human eye is to be observed, with the increase of temperature, the graphite oxide will increase, this time should be used to protect gas or vacuum to protect what you said is, nitrogen protection, and general protection of nitrogen can reach more than 2000 degrees, if the high temperature to 3800 degrees, will you say that vapor formed in graphite surface. To achieve this temperature, it is necessary to add inert gas to achieve, otherwise, can not reach, generally to 4350 degrees, the graphite began to soften.

- Q: After vacuum melting of quartz crucible, there are three graphite electrode rods. What's the adjustment?

- The shorter one is the farther away from the other, and the shorter one is the shorter one

- Q: What do carbon products include?

- High power electrode and ultra high power electrode. The carbon block can be divided into blast furnace carbon block, aluminum carbon block and electric furnace block. Carbon products can be divided into carbon products, graphite products, carbon fibers and graphite fibers according to the depth of processing. Carbon products can be divided into graphite products, carbon products, carbon fibers and special graphite products according to the raw materials and the production process. Carbon products according to their ash content, and can be divided into multi gray products and less ash products (including ash below l%).

Graphite electrodes are widely used in electric arc furnace and ladle refining furnace for steel making; and used in electric smelting furnace for producing ferroalloys, yellow phosphorus, corundum . The products are well sold to more than 30 countries and regions including Europe, America, Japan, Brazil, South Africa, Australia, the Middle East and so on , and enjoy good reputation.

We sincerely welcome domestic and overseas customers to our company for cooperation.

1. Manufacturer Overview

| Location | Liaoning,China (Mainland) |

| Year Established | 2006 |

| Annual Output Value | |

| Main Markets | South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Northern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | DALIAN,QINGDAO,XINGANG |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

UHP Graphite Electrode Plate (Dia250-800mm)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Tons m.t.

- Supply Capability:

- 1000 Tons per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords