Graphite Electrode with Good Quality Hot Sale for Electric Arc Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 700 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Graphite Electrode

Graphite electrode is made from the domestic first class petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The Graphite electrodes include: regular power, high power, ultra high power and square electrode. The range of diameters covers from 200mm to 800mm. Our products own the following characteristics: low electric resistivity, good electrical and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy.

CNBM and its partner have 4 production bases and the annual production capacity of graphite electrodes is 60,000 MT.

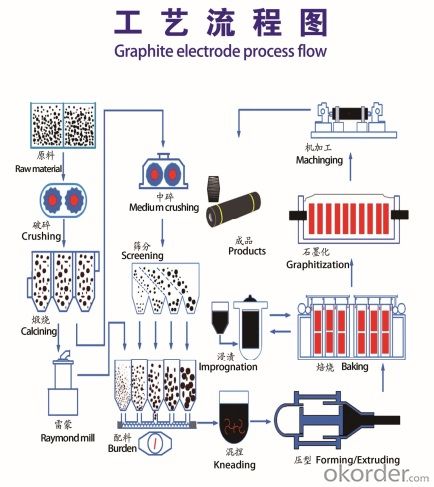

Graphite Electrode Process Flow

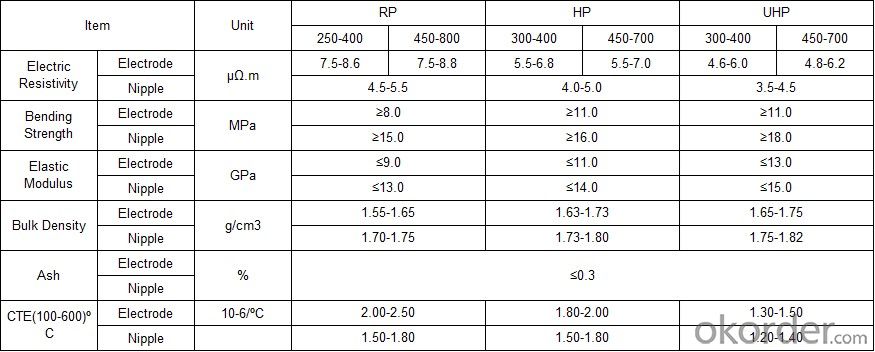

Technical Specifaication:

Company Profile

CNBM INTERNATIONAL CORPORATION

Build your world with our materials.

We are a primary subsidiary of China National Building Material Group Co., Ltd.

CNBM Group is a central government-owned enterprise and a Fortune Global 500 company (Ranking 203th in 2019). It is the largest building material manufacturer and service provider in the world, with 15 publicly-listed companies and over 180,000 employees (2019). We have more than 300 factory plants in China. For the refractory, we are top 3 in China. We have more than 17 plants in different cities.

Workshop

Quality Assurance & Control

· National Certified Laboratory

· Key testing instruments, including: specific resistor, bulk density meter, elasticmodulus meter, bending strength inspector, ash analysis meter, CTE analysis meter, etc.

· On-time instrument calibration

· On-site properties testing, including:

L-CTE,C-CTE

Specific resistance, bulk density,

Bending strength, ash content, elastic modulus

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your requirement.

- Q: Why is graphite conductive electrode oxidized?

- The reason for its oxidation is that it is oxidized at atmospheric temperature by reacting with the oxygen in the air

- Q: What is the difference between pyridine type nitrogen and graphite type nitrogen?

- In fact, this problem is very simple, the carbon graphite is six square lattice ordered, natural graphite and artificial graphite is divided into two kinds: the classification of natural graphite flake graphite and graphite is earthy, basically it is not forming soil shaped graphite graphite, are rough machining, the battery core and do more. The use ratio of flake graphite.

- Q: Graphite electrode specifications, graphite electrode manufacturers which good?

- Graphite electrode to Qingdao Chenyang graphite Co., quality assurance, trustworthy, we have been purchasing graphite electrode for them, you can ask them,

- Q: What are the structures of pyrolytic graphite electrodes? What are their properties and applications? We hope that some details will not be found

- The high purity graphite component is put into the furnace, and nitrogen and methane are produced under vacuum high temperature. Then graphite is shown to produce 10% coating.

- Q: The difference between graphite electrode and graphite rod

- The difference between an electrode and a rod is that the electrode has a lead conductor, and the rod is not.

- Q: Graphite powder produced by graphite electrode and what we usually call graphite is a kind of thing?

- Coal tar pitch as binder is made by calcination, batching, kneading, pressing, roasting, graphitization and machining

- Q: How should carbon deposits be treated?

- At certain temperature, can make alloy and carbon can react in the engine surface coated with a layer of graphene film, graphene nano particles can fill the pores, wear scratches, on the friction surface repair function.

- Q: How does graphite produce solar cells?

- Gerrit J said: "despite the modifications, but the inherent nature of graphene remains unchanged, is a significant advantage of composite materials."

- Q: What is anodized graphite?

- Electrochemical graphite is made of graphite, coke and other raw materials, placed in the high temperature of more than 2500 degrees in the furnace, processed into products.

- Q: What are pyrolytic graphite electrodes used for?

- (1) the processing speed is faster: normally, the mechanical processing speed of graphite can be 2~5 times faster than copper, while the discharge processing speed is 2~3 times faster than copper;More material is not easily deformed: obvious advantages in the processing of thin electrodes; copper softening point at about 1000 degrees, easily deformed by heat; graphite sublimation temperature is 3650 degrees; the thermal expansion coefficient of copper is only 1/30.

Send your message to us

Graphite Electrode with Good Quality Hot Sale for Electric Arc Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 700 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches