UHP Graphite Electrode Lithium Ion Battery Ladle Refining Furnace with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Ladle Refining Furnace Graphite Electrodes UHP with Nipples

1.Diameter: 200 to 700mm

2.Length: 1600 to 2400mm

3.Nipple:3-4TPI

Ladle Refining Furnace Graphite Electrodes UHP with Nipples

1. Grade: RP, HP, UHP, SHP, RPI

2. Diameter: 200 to 700mm at your choice.

3. Length: 1600 to 2400mm at your choice.

4. Nipple: 3-4 TPI

5. Fine mechanical strength and machining quality, low specific resistance, high temperature and oxidation resistance

6. Low price and timely delivery.

Feature

Ladle Refining Furnace Graphite Electrodes UHP with Nipples

Grades: RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

UHP

Physical and chemical index

Item | Unit | Nominal Diameter(mm) | |||

YB/T4088-2000 | Typical Values | ||||

Industry Standard | |||||

300-400 | 450-550 | 350-550 | |||

Resistance | Electrode | ohm | ≤6.2 | ≤6.5 | 4.6-6.2 |

Nipple | ≤5.5 | ≤5.5 | 3.5-4.5 | ||

Bending Strength | Electrode | Mpa | ≥10.5 | ≥10.0 | ≥11.0 |

Nipple | ≥16.0 | ≥16.0 | ≥18.0 | ||

Elastic Modulus | Electrode | Gpa | ≤14.0 | ≤14.0 | ≤13.0 |

Nipple | ≤18.0 | ≤18.0 | ≤17.0 | ||

Density | Electrode | g/cm3 | ≥1.65 | ≥1.64 | 1.65-1.72 |

Nipple | ≥1.72 | ≥1.70 | 1.75-1.82 | ||

Ash content | Electrode | % | ≤0.3 | ≤0.3 | ≤0.3 |

Nipple | |||||

CTE(100-600) | Electrode | 10-6/C | ≤1.5 | ≤1.5 | 1.20-1.40 |

Nipple | ≤1.4 | ≤1.4 | 1.10-1.30 | ||

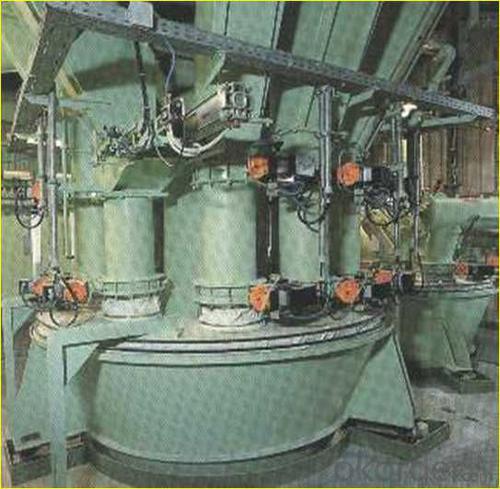

Image

Ladle Refining Furnace Graphite Electrodes UHP with Nipples

FAQ:

Ladle Refining Furnace Graphite Electrodes UHP with Nipples

1. Why it is essential to select electrode carefully for each particular furnace?

The primary factor is the maximum current intensity of the furnace. However, other conditions should also be considered, such as the characteristics of the furnace, type of charge, tap to tap time, oxygen blowing, mechanical requirement, furnace regulation, etc.Generally, specifications for electrodes of most grades have been standardized. Variation of physical characteristics with temperature, however, should be taken into account whenever using the electrodes.

Precautions to the use of graphite electrodes

2. Why it is essential to not to fit electrodes and nipples made by different manufacturers together?

The capacities of the furnace and the transformer determine whether the grade and diameter of the electrode are suitable to the furnace or not.

In order to prevent the electrode column from being hit by the collapsed furnace loads, large and heavy scraps should be loaded onto the bottom of the furnace. Do not put significant quantity of insulating materials such as lime and so on just under the electrode column, otherwise it would be difficult to power on the electrode column, or even break it.

electrode column may be hurt when it moves up and down if the furnace cover is out of the position.

When making a connection, lost or damaged pitch plugs must be replaced.

The reason must be found out if a gap appears between two electrodes after connection. The electrode column can only be loaded after the gap being eliminated.

The electrode column must be strictly perpendicular to the ground lever. Oblique column is not allowed during operation.

The holder must be placed between the two safety marks on the top electrode, otherwise the column may be broken.

Generally, different manufacturers may make their electrodes with different raw materials and processes, therefore the physical and chemical properties of their electrodes are usually different. Please do not fit electrodes and nipples made by different manufacturers together.

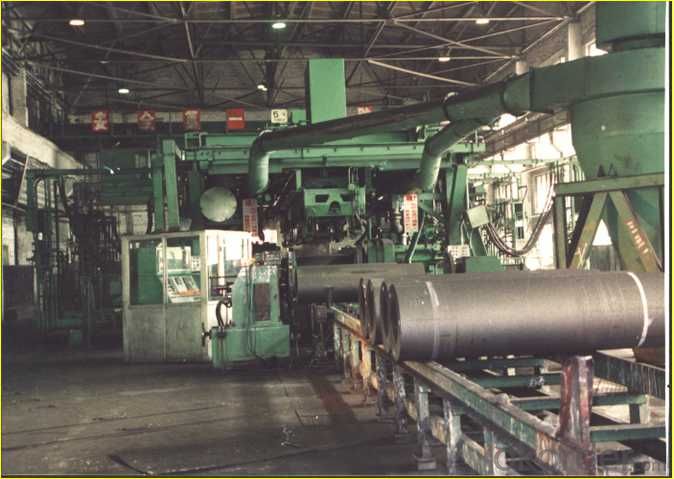

Applications

Ladle Refining Furnace Graphite Electrodes UHP with Nipples

Electrodes in electric arc furnace and ladle refining furnace for steel making;

Electrodes in electric smelting furnace for producing industrial silicon, yellow phosphorus, corundum and so on.

- Q: After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- Negative poleThe color becomes lighter (the copper ion gets electrons in the cathode and becomes copper)

- Q: Specification for graphite electrodes commonly used in steel works

- The variety and specifications of graphite electrodes used in modern EAF steelmaking are mainly determined by the technical parameters of the steelmaking furnace. With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: The original battery is not necessary to form the electrode potential? Why can we use graphite as electrode only? No potential difference.

- Indeed, the original battery electrode potential using two different electrodes, produce potential difference, so that the electron flow generated current. Graphite is used as an electrode because of its excellent electrical conductivity and stability

- Q: What kind of asphalt is better for natural graphite coating?

- Special graphite mainly to high quality petroleum coke as raw material, coal tar or synthetic resin as binder, the raw material preparation, mixing, kneading, pressing, crushing, mixing, molding, roasting, soaking, repeatedly repeated purification and graphitization, and made the processing machine. It is generally used in the aerospace, electronics and nuclear industry sectors. It includes pure graphite, high purity, high strength, high density and pyrolytic graphite.

- Q: Can graphite be used as an electrode for electrolysis of silver in silver nitrate?

- Xiaoyi Liyang said the principle is correct, but can get silver? I think we can solve the problem if we take proper measures to get the silver elements, such as separating the anode and the cathode from the salt water!

- Q: National standard for graphite electrodes

- Page 7 the international standard specifies the shape, dimensions and tolerances, technical requirements, test methods, packaging, marking, storage, transportation and quality certificates of graphite electrodes. This standard applies to high quality petroleum coke, asphalt, coke as the main raw material, through molding, roasting, impregnation, graphitization and mechanical processing made of, power supply arc furnace as conductive material of ordinary power graphite electrode. Common power graphite electrode GB

- Q: Can Naiduo high temperature graphite

- The reinforced graphite gasket is made of flexible graphite tape or flexible graphite and is molded into ring products of different sizes. Suitable for hot water, high temperature, high pressure steam, heat exchange liquid, nitrogen gas, organic solvent, hydrocarbon, low temperature liquid and other medium. Used in compressors, machines, pumps, valves, chemical instruments, instruments, etc..

- Q: The graphite electrode made by the machining center adopts cooling method, which is water cooled, oil cooled and blow cold. Which is good?

- In addition, the infiltration of water on graphite is not good, can not get the effect of dust removal. Now there are special graphite machine, sealing system. Air-cooled can be used, after all, the best air-cooled.

- Q: What do carbon products include?

- Carbon and graphite materials are mainly carbon based non-metallic solid materials, in which carbon material is basically composed of non graphitic carbon material, and graphite material is basically composed of graphite carbon material. For the sake of simplicity, carbon and graphite materials are sometimes referred to as carbon materials (or carbon materials).

- Q: Graphitized anode, cathode and graphite electrode, respectively How can one differentiate and use differently?

- Compared with other materials of graphite anode plate has high temperature resistance, good electrical and thermal conductivity, easy machining, good chemical stability, acid and alkali resistance, low ash content; for electrolytic solution, preparation of chlorine, caustic soda, salt alkali electrolytic solution preparation; application such as graphite anode plate can be used as conductive anode electrolytic salt solution preparation of caustic soda. Graphite anode plate can be used as conductive anode in electroplating industry. It is an ideal material for electroplating. It can make electroplating products have the advantages of smoothness, delicacy, wear resistance, corrosion resistance, high brightness and not easy to change color.

Send your message to us

UHP Graphite Electrode Lithium Ion Battery Ladle Refining Furnace with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches