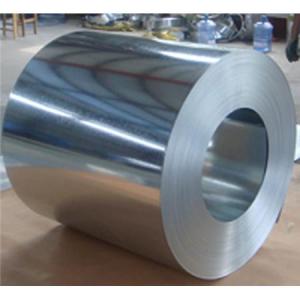

DX51D G350 Prime Spangle Hot Dip Galvanized Steel Coil GI Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DX51D G350 Prime Spangle Hot Dip Galvanized Steel Coil GI Coil

Details of the DX51D G350 Prime Spangle Hot Dip Galvanized Steel Coil GI Coil

| goods | Hot dip galvanized steel coil and sheet |

| Technical Standard: | JIS 3302 / ASTM A653 / EN10143/EN10327 |

| Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.17-1.6mm (0.25-0.45mm is the most advantage thickness) |

| Type of coating: | galvanized |

| Zinc coating | Z60-120g/m2 |

| Surface treatment | chromed / skin pass/ oiled /un oiled /slightly oiled/ dry |

| Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| MOQ | 5 Tons |

| Package: | Properly packed for ocean freight exportation in 20''containers |

| Price terms | FOB,CFR,CIF,CPT.CNF,CIP |

| Payment terms | 30%TT in advance+70% TT or irrevocable 70%L/C at sight |

| delivery time | 7days after receipt of 30% TT |

Specification of the DX51D G350 Prime Spangle Hot Dip Galvanized Steel Coil GI Coil

| Material | Tensile test | ||||||

| Rel | Rm (MPa) | Elongation | |||||

| (MPa) | 1.8~<2.0< span=""> | 2.0~<2.5< span=""> | 2.5~<3.2< span=""> | 3.2~<4.0< span=""> | ≥4.0 | ||

| SPHC | ≥270 | ≥29 | ≥30 | ≥31 | ≥32 | ≥32 | |

| SPHD | ≥270 | ≥32 | ≥33 | ≥35 | ≥37 | ≥39 | |

| SPHE | ≥270 | ≥33 | ≥35 | ≥37 | ≥39 | ≥41 | |

| SS330 | ≥205 | 330~430 | ≥26 | ||||

| SS400 | ≥245 | 400~510 | ≥24 | ||||

| SAPH370 | ≥370 | ≥255 | ≥32 | ||||

Supplier of the DX51D G350 Prime Spangle Hot Dip Galvanized Steel Coil GI Coil

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Delivery of the DX51D G350 Prime Spangle Hot Dip Galvanized Steel Coil GI Coil

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel perform in terms of creep resistance?

- Special steel typically performs very well in terms of creep resistance. Due to its unique composition and heat treatment, it can withstand high temperatures and prolonged stress without deforming or failing. This makes it an excellent choice for applications that require long-term stability under extreme conditions, such as in power plants or aerospace industry.

- Q: How is special steel heat treated?

- Special steel is heat treated through a process known as quenching and tempering. Initially, the steel is heated to a specific temperature and then rapidly cooled by quenching in a liquid medium such as oil or water. This rapid cooling helps to harden the steel. Subsequently, the steel is reheated to a lower temperature and held there for a certain period of time to relieve internal stress and improve toughness. This two-step process of quenching and tempering enhances the strength, hardness, and durability of special steel for various applications.

- Q: What are the machining techniques for special steel?

- Some of the machining techniques commonly used for special steel include milling, turning, drilling, grinding, and broaching. These techniques are employed to shape and finish the special steel material according to the desired specifications and requirements. Additionally, special attention is given to selecting appropriate cutting tools, speeds, and feeds to ensure efficient and precise machining.

- Q: How does special steel perform in high-temperature corrosion?

- Special steel has been specifically engineered to excel in environments with high-temperature corrosion. Its exceptional properties grant it exceptional resistance against oxidation and corrosive reactions when subjected to elevated temperatures. The high chromium content found in special steel is a key factor contributing to its performance in high-temperature corrosion. Chromium creates a protective oxide layer, referred to as a passive film, which functions as a barrier against corrosive elements. This passive film remains stable even under high temperatures, successfully preventing oxidation and corrosion. Furthermore, special steel often incorporates additional alloying elements like nickel, molybdenum, and titanium, which further enhance its ability to resist high-temperature corrosion. These elements augment the steel's capacity to withstand aggressive chemical environments typically encountered in industrial processes involving high temperatures and corrosive substances. Moreover, special steel is renowned for its remarkable mechanical properties, which encompass high strength and toughness. These qualities enable the steel to endure the harsh conditions associated with high-temperature corrosion. Even when exposed to extreme temperatures and corrosive chemicals, it can retain its structural integrity and dimensional stability. In conclusion, special steel's exceptional resistance against high-temperature corrosion makes it the ideal choice for various applications in industries such as petrochemical, power generation, and aerospace. Its capacity to maintain performance and durability in challenging environments guarantees the longevity and reliability of equipment and structures, ultimately reducing maintenance and replacement expenses.

- Q: What are the different methods of surface pickling for special steel?

- There are several methods of surface pickling that can be used for special steel. These methods include: 1. Acid Pickling: This is the most common method used for pickling special steel. It involves immersing the steel in an acid solution, usually hydrochloric acid or sulfuric acid, to remove any surface impurities. The acid reacts with the oxide layer on the steel, dissolving it and leaving behind a clean surface. 2. Electrolytic Pickling: In this method, an electric current is passed through the steel while it is immersed in an electrolyte solution. This causes a chemical reaction that removes the surface impurities. Electrolytic pickling is a more controlled process and can be used to achieve a more uniform surface finish compared to acid pickling. 3. Mechanical Pickling: This method involves using mechanical means to remove the surface impurities from the steel. It can be done using abrasive materials, such as sandpaper or wire brushes, to physically scrub the surface and remove any scale or rust. Mechanical pickling is often used in combination with acid or electrolytic pickling to achieve the desired surface finish. 4. Passivation: After pickling, special steel can undergo passivation to enhance its corrosion resistance. Passivation involves treating the steel with a chemical solution, typically nitric acid or citric acid, to create a protective oxide layer on the surface. This layer helps to prevent further corrosion and improves the overall durability of the steel. It is important to note that the specific method of surface pickling used for special steel may vary depending on the type of steel, the desired surface finish, and the intended application. Therefore, it is crucial to consult with experts or follow the manufacturer's guidelines to ensure the appropriate method is used for pickling special steel.

- Q: What are the characteristics of tool steel?

- Tool steel is a type of steel that possesses exceptional hardness, strength, and wear resistance, making it ideal for manufacturing various tools. It typically contains high levels of carbon, along with other alloying elements like chromium, vanadium, and tungsten. Tool steel also exhibits good toughness, heat resistance, and ability to retain sharpness. Additionally, it can be hardened and tempered to achieve desired properties for specific applications.

- Q: What are the common alloying elements in special steel?

- The common alloying elements in special steel are chromium, manganese, molybdenum, nickel, and vanadium.

- Q: How is special steel used in the manufacturing of tools and dies?

- Special steel is used in the manufacturing of tools and dies due to its exceptional properties, such as high strength, hardness, and wear resistance. These steels can withstand extreme temperatures and pressures during the forming, cutting, and shaping processes. They also have excellent dimensional stability, ensuring precise and accurate tooling. Special steel's unique composition and heat treatment capabilities allow for the production of durable and long-lasting tools and dies, which are essential for various industries like automotive, aerospace, and manufacturing.

- Q: How does special steel perform in high-temperature fatigue resistance?

- Special steel is known for its excellent performance in high-temperature fatigue resistance. Unlike ordinary steel, special steel contains alloying elements such as chromium, nickel, and molybdenum, which enhance its mechanical properties and resistance to fatigue at elevated temperatures. At high temperatures, the microstructure of special steel undergoes significant changes, which can lead to the initiation and propagation of cracks. However, the presence of alloying elements in special steel helps to stabilize the microstructure, preventing the formation and growth of cracks. This ensures that the material can withstand cyclic loading and retain its structural integrity even under extreme temperature conditions. Additionally, special steel exhibits superior heat resistance, which allows it to maintain its mechanical strength and hardness at high temperatures. This property is crucial in applications where components are subjected to repetitive thermal cycles or exposed to continuous high temperatures, such as in gas turbines, power plants, and aerospace engines. Furthermore, the high-temperature fatigue resistance of special steel is also influenced by its composition and heat treatment. Through precise control of the alloying elements and appropriate heat treatment processes, the material's fatigue life and resistance to thermal fatigue can be further enhanced. In conclusion, special steel performs exceptionally well in high-temperature fatigue resistance due to its unique composition and microstructure. Its ability to withstand cyclic loading, maintain mechanical properties, and resist crack formation under extreme temperature conditions makes it a preferred choice for demanding applications in various industries.

- Q: What are the applications of special steel in the oil and gas supply chain?

- Special steel has various applications in the oil and gas supply chain. It is commonly used in the construction of pipelines, drilling equipment, and offshore platforms. Special steel's high strength, corrosion resistance, and ability to withstand extreme temperatures make it ideal for these applications. Additionally, special steel is used in the manufacturing of valves, fittings, and other components that are crucial for the efficient and safe operation of the oil and gas supply chain.

Send your message to us

DX51D G350 Prime Spangle Hot Dip Galvanized Steel Coil GI Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords