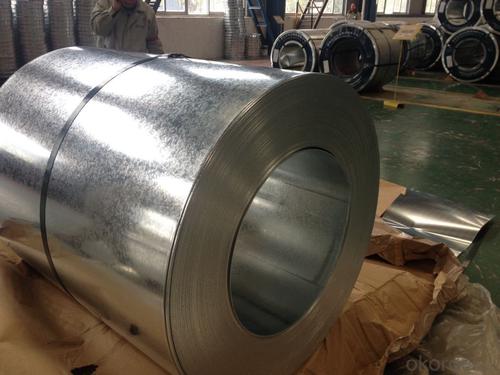

Hot Dipped Galvanized Steel Coil in Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Dip Galvanized Steel Coil in Coil

Description:

Galvanized Steel Coil gets coated in layers of zinc because rust won't attack this protective metal. The most external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel. For countless outdoor, marine, or industrial applications, Galvanized Steel Coil is an essential fabrication component.

Superiority:

1. Good Resistance to Corrosion

2. Qualified Processing Machinability

3. High Thermal Resistance

4. Excellent Reflectivity

5. Inexpensive and effective enough

6. Can be recycled and reused multiple times

Application:

1. Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds

2. Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts

3. Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

4. Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Product Specification:

Material:SGCC,DX51D,Q195

Thickness: 0.3-3.0mm

Width: 600-1500mm

Inner Diameter: 508mm, 610mm

Weight of Steel Coil: 3-15MT

Coating Type: Al-Zn Alloy

Available Dipped Layer: 50-150g/m2

Surface Finish Structure: Normal Spangle & Small Spangle & Zero Spangle

Steel grade & Standard: JIS G3302 SGCC

Spangle: Normal spangle, large spangle, small(min) spangle, zero spangle

FAQ:

1.How about the package for the Hot Dip Galvanized Steel in Coil?

Usually Standard export seaworthy package: waterproof paper+steel trip packed+wooden case seaworthy package

2. Can I know the production period of the goods?

Usually it need 20 days for 25tons in one container. We can produce 300 tons per day but we need to arrange the production in advance.

3. How about the label, could you make the label according to pour requirements?

Usually we use the MILL label, but if you need special form we can make.

- Q: which pokemon has the most steel pokemon???

- Transformers.

- Q: Steel is no doubt a better constructin material but it is only in practice in developed country.i would like that we should high lights the benifits and negatives of steel to make the steel more clear as a construction material.Hope some expert to address this topicMD

- Steel Structure considered as the most efficient and fast in completion of any project, specially the high rise buildings, also the logistics during construction is less complicated than the normal methods, Steel Structure has so many advantages vs the disadvantages, and highly recommended for commercial buildings

- Q: it isn't a SIGG water bottle or any other brand, as it's from thingsengraved what I'm wondering is, is this just as good as a SIGG water bottle, or is there any difference?

- Stainless steel is one of the best products to use for anything associated with food. It can be sterilized, it won't stain or absorb odors, it can be recycled and much of it is made of recycled material. If you take care of it, it can last a lifetime. We get hung up on brand names, you should look at the material it is made of. Which is a quality grade of stainless steel. I couldn't find the grade on the Sigg site, but I would think it would be the same or very similar. So, all that to say, this one seems to be as good as a Sigg.

- Q: How is it used easy 10 points just tell me how its used or any intersting facts this is for my comp science paper lol. I know what the hell does steel have to too do with computers he is a Fg! Please be descriptive THANKS! FAST ANSWERS TOO it 9pm bedtime for a 14 year old lol..

- steel is used for cars and trains. one of the largest steel manufacturers is in my town its called CarTech its in reading pa.

- Q: What are the common coil handling equipment used in the industry?

- Some common coil handling equipment used in the industry are coil cradles, coil reels, coil straighteners, coil feeders, and coil transfer cars. These tools are essential for safe and efficient handling of coiled materials during various manufacturing processes.

- Q: What are the different methods of steel coil surface cleaning?

- There are several different methods of steel coil surface cleaning, including mechanical cleaning, chemical cleaning, and high-pressure water cleaning. Mechanical cleaning involves using abrasive materials or brushes to remove dirt, rust, and other contaminants from the surface of the steel coil. Chemical cleaning involves using chemicals or solvents to dissolve or remove contaminants from the surface. High-pressure water cleaning uses water jets at high pressures to remove dirt and debris from the surface. Each method has its own advantages and is chosen based on the specific requirements and condition of the steel coil.

- Q: I completed the missions in broken steel like: the one of the rangers, the one of vault 101, the one of the enclave, and several others.are there any more INTERESTING missions?

- Um The ranger mission is not broken steel and Vault 101 isn't either. After completing Broken steel you should go to this guy called griffon in underworld and talk to him about him getting aqua pura(Or aqua cura) Then after he brings you to 2 other quests from this guy called bigsley. Thats all I could find thats interesting. You should go to a place called oasis. Its at the very top of the map, Small quest up there but really cool. Go look it up on youtube if you want. You could also go to paradise falls and kill all the slavers and save the slaves, That gets you a quest and a achievement if you free them. Also the guard at paradise has a quest for you. Also has a achievement, The quest is called strictly business, Its more of a evil karma quest though. if you don't want to be evil just take the cool weapon he gives you then kill him :P, all i can think of right now. if you have a hard time finding places for stuff, Youtube might help. or getting the explorer perk.

- Q: So I want to get my 3+ wood shafted with a dynamic gold shaft because i need a stiffer shaft but dont want to spend much on it.I've never swung a steel shafted wood, but I hear that it is more consistent that graphite....Plus, since the cost of steel is only $15 compared to the $65 graphite, not to mention installation charges.So yeah...... How good is steel for fairway woods?BTW, my swing speed is about 95 but i can amp it up to 110 (with control, that is)

- i take advantage of a three timber off the tee while a motive force could bypass in the process the fairway on a dogleg, or while the fairway gets narrower the further you hit it. Use it to get as close to to a par 5 in 2 as i will, or perhaps even attain a par 5 in 2. Use it to make up floor in case you permit out a rigidity, every time the photos demands me to hit it between 220 and 235 it quite is approximately how some distance I hit my 3 timber. I additionally carry a 5 timber which I hit approximately 2 hundred to 215 and extremely severe so it lands comfortable. i do no longer carry any hybrids regardless of the undeniable fact that as I nevertheless like to hit long irons.

- Q: Steels like YHB-2, MVS-8, and SK-5. Also if you know anything about these steels that would be helpful.

- White steel is a common shorthand name for white paper steel (shirogami hagane) which can be any of several fairly simple high carbon, water hardening steel grades. The carbon content varies by grade, and runs from 0.8 to 1.4%. The range of carbon content within a grade is a tight 0.1%. For example, the carbon content of Shirogami Hagani No1A is specified to be between 1.3 and 1.4%. Each grade also contains 0.1-0.2% silicon and 0.2-0.3% manganese, and only trace amounts of the impurities sulfur and phosphorus. Blue paper steel (aogami hagane) is also offered in several grades, with carbon content ranging similarly to the white grades. However, blue steel contains the additional alloying elements chromium and tungsten, and one grade (aogami super) also contains molybdenum and vanadium. The blue steels can be quenched in water or oil, whereas most of the white grades need a faster quench and require water.

- Q: How are steel coils used in the manufacturing of transmission shafts?

- Steel coils are used in the manufacturing of transmission shafts by being converted into cylindrical shapes through a process known as coil winding. These coils are then cut, shaped, and machined to create the desired dimensions and specifications for the transmission shafts. The high strength and durability properties of steel make it an ideal material for transmission shafts, ensuring efficient power transmission and overall performance of the machinery.

Send your message to us

Hot Dipped Galvanized Steel Coil in Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords