GI Hot-Dip Galvanized Steel Coil Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

3.Galvanized Steel Coil Images

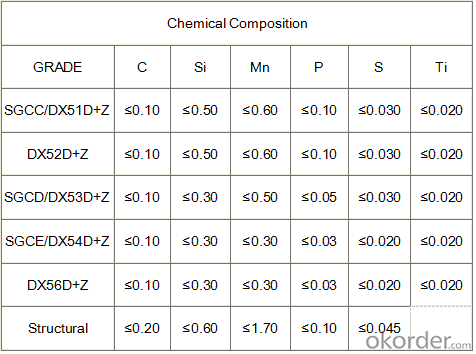

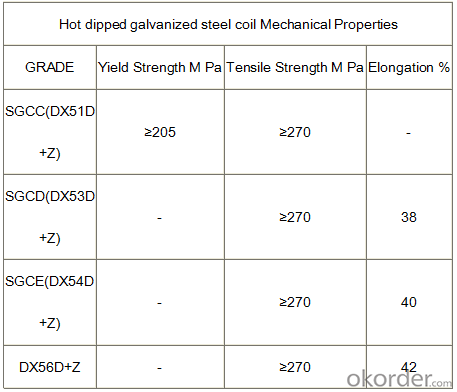

4.Galvanized Steel Coil Specification

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

3.How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What is the (balanced) chemical equation for steel?

- Steel is about 5% carbon and about 89 % iron, the rest is impurities of all sorts That is considered low carbon steel There are precise formulas for other steels like High Speed Steel, High Tensile low carbon, and thousands of other steels. Specialty steels are a big business item with thousand of tons sold each year for specialty applications.

- Q: i have a sword and some knives that have this grade steel. so is it a high grade or low grade? and how can i tell the differance between a high grade and a low grade?

- Type 440—a higher grade of cutlery steel, with more carbon in it, which allows for much better edge retention when the steel is heat treated properly. It can be hardened to Rockwell 58 hardness, making it one of the hardest stainless steels. Also known as razor blade steel. Available in three grades 440A, 440B, 440C (more common) and 440F (free machinable).

- Q: I have one and wonder how much force this can take since it does seem like you can bend it(Sure it's impossible with hands), but I don't want to try that cause i don't want to break it. Many people say that it's really hard and can handle a hammer smash? is that true and can it even make it through more force. Cause steel is harder than iron and iron is pretty hard... So how much can i trust this locks security, i mean if i put at at a door would some thiefes be able to break it, if they had the right tools??

- any pair of larger bolt cutters would whack right thru that lock brother. use it, but put a backup lock on somewhere else too. thx for the pic!

- Q: Can steel coils be coated with color-changing materials?

- Yes, steel coils can be coated with color-changing materials. These materials are typically applied as a topcoat or overcoat on the steel surface, allowing the coils to exhibit different colors or hues based on external factors such as temperature, light, or chemical reactions. This coating technology can provide visual appeal, aesthetic versatility, and even functional benefits to steel coils in various applications.

- Q: What are the different types of steel coil slitting processes?

- There are several types of steel coil slitting processes, including rotary slitting, loop slitting, and pull-through slitting.

- Q: can steel boil and turn into a gaseous state?? if so how hot does it have to be for it to boil

- hahah umm ya u could boil steel but prob not at your house hahah and the boiling point of a medium carbon steel to be around 3000K

- Q: Why do we galvanise steel? Galvanised steel is steel coated with zinc.

- it prevents the steel from rusting. Zinc rusts too, but more slowly than steel, and it doesn't tend to eat away it's structure. Zinc coatings prevent oxidation of the protected metal by forming a barrier, and by acting as a sacrificial anode if this barrier is damaged. Zinc oxide is a fine white dust that (in contrast to iron oxide) does not cause a breakdown of the substrate's surface integrity as it is formed. Indeed the zinc oxide, if undisturbed, can act as a barrier to further oxidation, in a way similar to the protection afforded to aluminium and stainless steels by their oxide layers.

- Q: So we all know a 1000lb steel ball will sink in water, but if you were to leave the center of the ball hollow and fill with air, if the steel ball was big enough in diameter it should float correct? What size would the steel ball need to be to float?

- specific gravity of a steel is approximately 7.82 as compared to water. so, the hollow sphere(filled with air) is having volume more by 7.82 as compared to solid sphere, then the 1000 lb hollow steel ball float in the water (Why Do Ships Float? The Greek Mathematician and inventor Archimedes lived during the 3rd century BC. According to history he was in the bath one day when he discovered the principle of buoyancy which is the reason why huge Greek ships weighing thousands of pounds could float on water. He noticed that as he lowered himself into the bath, the water displaced by his body overflowed the sides and he realised that there was a relationship between his weight and the volume of water displaced. It is said that he ran naked into the street yelling heurEka which is where we get our word eureka! (I found it), Greek heurEka I have found, from heuriskein to find. The Buoyancy Principle: Archimedes continued to do more experiments and came up with a buoyancy principle, that a ship will float when the weight of the water it displaces equals the weight of the ship and anything will float if it is shaped to displace its own weight of water before it reaches the point where it will submerge. This is kind of a technical way of looking at it. A ship that is launched sinks into the sea until the weight of the water it displaces is equal to its own weight. As the ship is loaded, it sinks deeper, displacing more water, and so the magnitude of the buoyant force continuously matches the weight of the ship and its cargo.)

- Q: aLSO, DOES STEEL C45 REFER TO THE CARBON IN IT?ALSO, WHAT IS AIRCRAFT GRADE PLYWOOD AND WHERE DOES ONE GET IT

- chromium nickle steel aka stainless steel exact amount of chrome and nickle will determine type/grade numbers Check the google for steel type/grade Never head of aircraft grade, however,, there is marine grade - normally baltic birch with waterproof glue and no defects i.e. knots, etc. Very strong (also quite expensive) but worth it for the correct applications

- Q: Can steel coils be used in outdoor applications?

- Indeed, outdoor applications can make use of steel coils. Steel, recognized for its resilience and robustness, proves to be ideal for various outdoor purposes. Commonly utilized in construction, automotive manufacturing, and transportation industries, steel coils exhibit resistance against adverse weather conditions like rain, snow, and UV exposure. Furthermore, to enhance their durability and prolong their lifespan, steel coils frequently undergo protective finishes such as galvanized or painted coatings. Ultimately, owing to their strength, durability, and ability to withstand environmental factors, steel coils emerge as a dependable and versatile choice for outdoor applications.

Send your message to us

GI Hot-Dip Galvanized Steel Coil Prime Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords