Galvanized Steel Coil/GI in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

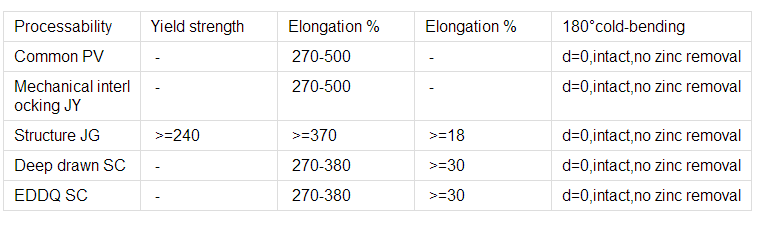

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils inspected for surface quality?

- Steel coils are inspected for surface quality through a meticulous process that involves various methods and technologies. The inspection is crucial as it ensures the coils meet the required standards and are free from any defects or imperfections. Here are the steps involved in inspecting steel coils for surface quality: 1. Visual Inspection: Initially, the coils undergo a visual inspection where trained personnel visually examine the entire surface for any visible defects such as scratches, dents, or any irregularities. This step helps identify any obvious issues that can be detected through visual observation. 2. Magnetic Particle Inspection: This non-destructive testing method involves applying a magnetic field to the steel coil's surface and then applying a magnetic particle solution. Any surface cracks or defects will cause the magnetic particles to cluster, making them visible under proper lighting. This technique is highly effective in detecting surface cracks and other surface abnormalities. 3. Eddy Current Testing: This method of inspection utilizes electromagnetic induction to identify surface defects. An eddy current probe is passed over the steel coil's surface, and any variations in the electrical current induced by the magnetic field will be detected. This technique is particularly useful for detecting surface cracks, pits, or corrosion on the coil's surface. 4. Ultrasonic Testing: Ultrasonic waves are used to inspect the steel coil's surface for any hidden defects such as subsurface cracks or inclusions. High-frequency sound waves are transmitted into the material, and any changes in the sound wave pattern that are reflected back indicate the presence of defects. Ultrasonic testing is highly reliable and can detect even the smallest defects within the steel coil. 5. Surface Roughness Measurement: The surface roughness of the steel coil is measured using specialized equipment. This measurement helps determine if the surface meets the required smoothness standards. The equipment scans the surface and provides detailed information about the roughness, enabling the inspector to ensure it falls within the acceptable range. Overall, steel coils undergo a comprehensive inspection process that combines visual examination with advanced testing methods such as magnetic particle inspection, eddy current testing, ultrasonic testing, and surface roughness measurement. These inspection techniques help identify and evaluate any potential defects or surface irregularities, ensuring that the steel coils meet the required surface quality standards.

- Q: What are the typical tolerances for steel coils?

- The typical tolerances for steel coils can vary depending on the specific requirements and standards of the industry. However, common tolerances for steel coils typically range between +/- 0.005 to 0.020 inches in terms of thickness, width, and length. These tolerances ensure that the steel coils meet the desired specifications and can be used effectively in various applications.

- Q: What are the dimensions of steel coils used in the appliance industry?

- The dimensions of steel coils used in the appliance industry can vary depending on the specific application and manufacturer. However, common dimensions for steel coils in the appliance industry range from 0.15mm to 6mm in thickness and 600mm to 2000mm in width.

- Q: like building steel beams. i'm pretty sure with a sawzall.

- Most I-beams are manufactured in a factory by rolling the red hot steel billet through several sets of rolls till the I-beam takes it's final shape. All we normally do to a factory stock I-beam is cut it to length, trim the ends, punch out the mounting holes and or weld on shear tabs. Some I-beams like tapered ones are built from scratch in the shop using plate steel. In fabricating in the shop, a plasma cutter or cutting torch is used along with a hydraulic plate shear. Repairs during erection, usually a cutting torch because you are several stories in the air. If the beam has to be taken to the ground, still a cutting torch because on a job site power availability is poor to connect a plasma cutter. Wingman

- Q: I am wondering if i can use my western guitar as a kind of steel-guitar, read something about it on Wikipedia.

- Musical style speaks volumes while it includes this concern. people who % severe quantity would be unhappy with unamplified nylon string guitars. From my attitude, the common distinction between metallic and nylon is this: metallic strings ring and nylon strings resonate. the quantity produced by employing metallic is frequently plenty greater suitable than nylon yet, to my way of thinking, the sound resonance produced by employing the wood of your guitar is largely masked by employing metallic strings. in case you have a decently made guitar (frequently, around 1000 money and up), the sound interaction between the wood and the strings in a nylon guitar is magical around the completed frequency selection. With a metallic string guitar, the sound produced by employing the vibrating string overpowers the wood resonance in any respect yet low frequencies. in my view, i will take a nylon string guitar any day for the sensitivity gained from the interaction between wood and vibrating string.

- Q: given the buoyant economic growth of india, what you guys think about steel industry? what can be the major issues in this industry in the coming days

- NAFTA became a unfastened commerce contract it is fairly a lot a republican proper. unfastened markets are a sturdy element. each and every so often unfastened markets deliver approximately the shortcoming of jobs in one sector yet that would not advise unfastened commerce is undesirable. opposition like that ensures that capital is spent in it is best way. Proping up death industries isn't a sturdy concept. i know it is not a favored element to declare, even though it is the certainty. would desire to we've propped up the horse and carriage marketplace while autos got here alongside so as that horse handlers did not lose thier jobs? in all risk not. unfastened commerce is a sturdy element. That being mentioned, i don't think of that Obama will merely blanketly wipe out any coverage by means of fact it became a Bush coverage. he isn't that stupid. If it became a sturdy coverage that labored, i'm particular it will be retained.

- Q: How are steel coils used in the manufacturing industry?

- Steel coils are widely used in the manufacturing industry as they are essential for various applications such as automotive, construction, appliances, and machinery. These coils are commonly used to produce various metal components and parts, including sheet metal, pipes, tubes, and wire. The coils are unwound and fed into different machines and processes, where they are shaped, cut, stamped, or welded to create the desired products. Due to their durability, strength, and malleability, steel coils are highly valued for their versatility and play a crucial role in the manufacturing industry.

- Q: I like steel strings but don't want to get a new guitar. Is that my only option?

- Don't EVER put steel strings on a nylon stringed guitar. Steel strings have many times more tension than nylon strings. The bodies on nylon stringed guitars are braced lighter than their steel stringed cousins. If you put steel strings on a guitar designed for nylon, they will belly the top up as well as warp the neck. Since they're attached differently, you'd (luckily) have a hard time even getting steel strings to fit. Enjoy your nylon string guitar for what it is, and if you want to play steel strings, buy a guitar designed for them.

- Q: The Chinese invented the windmill long before the 1800's, but I cannot find anywhere who invented the steel windmill, I believe it was in the 1800'sIf you know the answer that'd be great!And also if you could find the date it was patented? Thanks SO much!

- The Steel Eclipse Type WG was the first of several self-oiling steel windmills marketed by Fairbanks, Morse, and Company after they became the distributor of all the Eclipse mills about the start of the 20th Century. It has the more important distinction of having been the only widely distributed worm-gear mill in the history of American windmill manufacture. Produced from about 1926 to the mid-1930's, the Steel Eclipse remains in the field today in considerable number in most parts of the country. Hope this helps!

- Q: I would like to know the process of making steel from the mining of ore to the final product. Can anybody offer some help? Either where to look, or the process itself. I would like to have included the different options with which to make steel. Through scrap metal, or iron ore briquettes etc... Thanks.

- I believe you are asking about two vastly different processes. This is science so, if you want a specific answer, you have to ask specific questions. VERY Basically... 1) Pig iron production works by melting iron and pouring it into molds that produce ingots called pigs. 2) fraction distillation separates different substances (typically starting in liquid form) by controlled heating so, since different substances boil at different temperatures, the vapors can be captured selectively.

Send your message to us

Galvanized Steel Coil/GI in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords