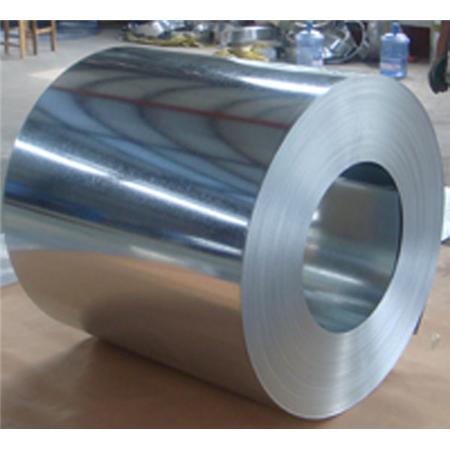

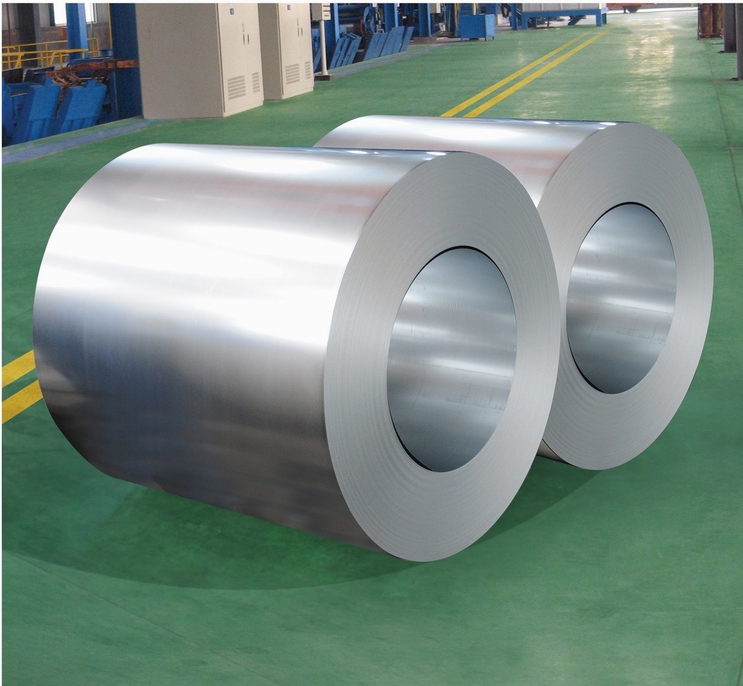

Prime Hot dip galvanized steel coil--SGCC DX51D

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 Mt m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanzied steel coil

Standard | JIS G 3302, ASTM A653, EN10327,10143,GB/T 2518 |

Grade | SPCC, DX51D+Z,CS Type A.B.C |

Zinc Coating | galvanized(GI) |

Zinc Weight | 40~140/m2 |

Thickness | 0.18mm~1.2mm |

Width | 762mm-1,250mm |

Coil weight | 3-20 tons |

Surface processing | Zero Spangle |

Coil Chemical Processing | Skin Pass,chromate,dry,oiled |

packing | waterproof paper and galvanized steel protection cover and steel strip packed Or as you request. |

Application | Construction, hardware, home appliances, interior decoration... |

Advantages | 1. Good experience producing and trading on PPGI/galvanized steel coil /steel sheet. With quality assurance and certification . 2.With technology strength and powerful. 3. Shortest delivery time . 4. authentication service and Sincere Caring Services. 5. We strive to be NO.1 of the same trade |

If you have any need of GI or PPGI Coil, please feel free to contact me, then the lowset price will be send to you immediately.

Alena

- Q: How do steel coils contribute to the renewable energy equipment industry?

- The renewable energy equipment industry relies heavily on steel coils, as they are a crucial component in the manufacturing process of various renewable energy technologies. Wind turbines, in particular, heavily rely on steel coils for their construction. The tower, nacelle, and rotor blades of wind turbines all require steel coils. When it comes to wind turbine towers, steel coils are used to fabricate the structural components that provide stability and support. These coils are rolled and welded together to form the tower, ensuring its strength and durability against the wind forces. Steel coils are also used in the production of the nacelle, which houses the generator and other essential components. Steel coils also play a significant role in the manufacturing of rotor blades for wind turbines. These blades are responsible for capturing wind energy and converting it into rotational energy. Steel coils are used to create the internal structure of the blades, providing the necessary strength to withstand the aerodynamic forces. These coils are often combined with composite materials to optimize the performance and efficiency of the blades. In addition to wind turbines, steel coils are utilized in other renewable energy technologies such as solar panels. In the manufacturing process of solar panels, steel coils are used to create frames and supporting structures that hold the photovoltaic cells in place. These frames ensure the stability and longevity of the solar panels, allowing them to effectively capture sunlight and convert it into electricity. To summarize, steel coils are an integral part of the renewable energy equipment industry. They provide the strength, durability, and structural support required by various renewable energy technologies. By enabling the production of wind turbines, solar panels, and other renewable energy equipment, steel coils contribute to the expansion and development of the renewable energy sector. This advancement is crucial in the global transition towards cleaner and more sustainable sources of energy.

- Q: How are steel coils used in the aerospace industry?

- Steel coils are used in the aerospace industry for various applications such as structural components, engine parts, and aircraft frame construction. These coils are often used in the manufacturing process to fabricate strong and durable components that can withstand the extreme conditions of flight.

- Q: How are steel coils used in the manufacturing of construction formwork?

- Steel coils are used in the manufacturing of construction formwork to provide structural support and reinforcement. These coils are typically processed and formed into various shapes and sizes, which are then used as a framework or mold for pouring concrete. The strength and durability of steel coils make them ideal for withstanding the weight and pressure of the poured concrete, ensuring the stability and integrity of the formwork structure.

- Q: How are steel coils inspected for surface cleanliness during processing?

- Steel coils are inspected for surface cleanliness during processing through various methods such as visual inspection, magnetic particle inspection, and ultrasonic testing. These methods help identify any contaminants, defects, or surface irregularities that may affect the quality of the steel coils.

- Q: What bike companies make the best Steel Road bikes?

- Lots of good companies out there. Surly Pacer is one to check out.

- Q: What are the different types of steel alloys used in coils?

- There are various types of steel alloys used in coils, including carbon steel, stainless steel, galvanized steel, and electrical steel.

- Q: What are the main factors that affect the paint adhesion on steel coils?

- The main factors that affect paint adhesion on steel coils are surface cleanliness, surface roughness, presence of contaminants, proper surface preparation, and the type of paint or coating being used.

- Q: I am planning to buy a Walther P22. I have liked the Pistol's performance-superb.The only confusion that I have is about the Polymer Frame.Just for this I may shift to someother manufacturer.Are Polymer Frames better than Steel in durability and lifespan.Walther says YES.Any comments on this...Practical users...Thanks in advance

- All polymer frames are cast around steel 'skeleton' inserts, which bear the stress and wear between receiver slide, as well as other wear points. The great advantage to polymer frames is the lower weight over the polymer composite compared to an all-steel or other metal alloy receiver frame. As all wear contact points are 'steel-to-steel', the service life expectancy of a polymer-frame weapon will be the same as an all-steel frame design. NO polymer-frame design I know of has ANY stress or load contact points between metal and polymer-only surfaces. My polymer-frame H-K USP and my Glocks are constructed this way.

- Q: I need help my new stainless steel cookware is sticking ? My first meal was nasty!

- Welcome to the life of stainless steel cookware. Make sure you have plenty of steel wool handy. It took my wife and I some getting used to, but we now love our set.

- Q: i am working a client.my vendor specified in pipe specification pipe line class as MS1 (code for Mild steel)but assigned material to this code is cs smls astm A 106B.my question is any difference between CS and MS material?pls suggest me

- CS is a noxious gas that I have tasted. If it is spec mild steel then do so.

Send your message to us

Prime Hot dip galvanized steel coil--SGCC DX51D

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 Mt m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords