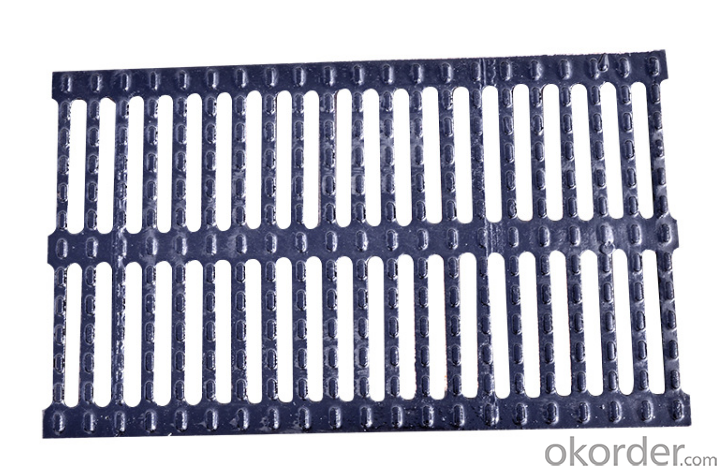

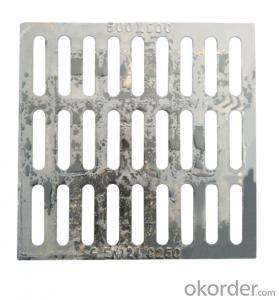

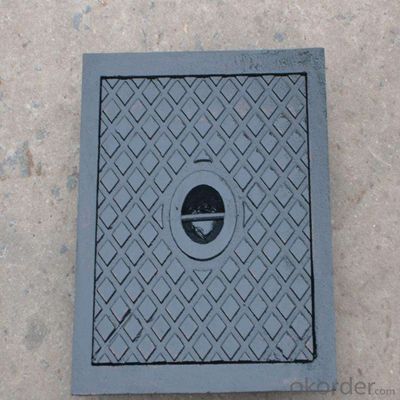

Ductile Iron Sewer Square Manhole Cover EN124 D400 Heavy Duty

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 3900 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron,

3) Type:round type and Square type,triangle

4) Sand casting,

5).we can produce as per customers'drawings

6)ISO9001:2000

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than.

Contain no metal and no recovery value, anti-theft.

Pictures

Features

1.High Intensity

It adopts macromolecule complex material and reinforcing steel bar moulded by high temperature and press at one time.

2.Durable

Acid-alkali and corrosion resistance; anti-rust; insulation; weatherability; excellent anti-pressure capability.

3.Unique appearance

Rich colors;the cover is not sprayed in surface but painted in whole material so that the color can keep lasted.

4.Competitive price

The price of compound manhole cover is lower than stipulated standard cast iron ones.

5.Save mine resource

It is made by regenerated resin or regenerated plastic raw material, which save application of cast iron.

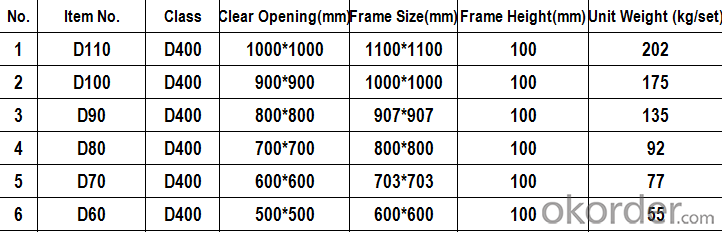

Specifications

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers.

FAQ

About Sample

Q : Can I get free samples?

A: Yes, we can provide you the free sample, but you have to bear the delivery costs.

About Customer Logo

Q: Can I have my own logo on the product?

A: Yes, you can send your logo design to us and send us the authority letter. Then we can cast the logo on body.

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: What are the requirements for casting steel castings?

- 4 thickness, most should be placed above the.5 and try to reduce the number of.6, the sand core should be used in classification of flat surface

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- 2 improve the crystal structure, enhance the formation and stability of spherical carbon crystal;Forgings are generally stress bearing members, and most of them are made of high strength medium carbon steel (alloy), which is formed by forging and fine crystalline. After the shell is annealed or quenched and tempered, the mechanical properties of the shell are more superior, and it has better strength and better elasticity;Welding materials.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Especially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: In theory, which is more expensive, forging parts or casting parts?

- It depends on the structure. In theory, the shape of the forging is relatively simple, but the requirement of internal structure is relatively high

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Uneven casting density is caused by uneven shrinkage of the casting during solidification.

- Q: How to cast iron and wrought iron collocation

- So we can only watch and ear distinction: 1, see: Iron fracture is rough, showing a bead (for the sake of coarse grain iron), and wrought iron fracture is generally more smooth; if this is a new fracture, but also to see the dark and shiny born iron wrought iron pig iron is bright; the fracture is generally irregular, because it is very brittle, mostly is interrupted, (which is processed, it is very flat and wrought iron) must not be interrupted, mostly by certain way processed separately, so the fracture is generally neat; if the fracture is that is cutting, wrought iron, iron is not cutting; iron surface will not have pores, familiar iron porosity; if a piece of iron is a significant deformation (bending) that is wrought iron because of poor plasticity It doesn't have to be so deformed, it's really bent, or it's broken, or it's obviously cracked, and it doesn't bend very much. There are some details that can not be made clear. It is necessary to have some experience.

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Increase the refractoriness and looseness of core sand

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting. It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

Send your message to us

Ductile Iron Sewer Square Manhole Cover EN124 D400 Heavy Duty

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 3900 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords