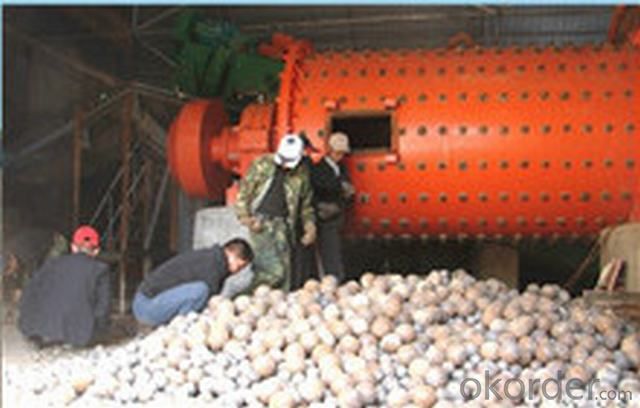

Forged Grinding Media Balls Highly Durable Long Lasting

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(1).Raw material: Round steel ,the raw material of forged balls ,are totally ordered from our national large -scale steel mills. We can also provide special processing as per special requirements of different grinding balls

Materials.

(2).Scientific Proportioning :Rational chemical composition is gradually optimized and formed by our technical staff after continuous tests. It is unique .The best configuration of various alloying elements can combine the ball′s hardness and toughness’ at their best.

(3).Electric furnace smelting: All cast steel balls are produced by intermediate frequency electric furnace .The purity and stability of materials are effectively ensured after uniform temperatures conditioning and twice hot metal purificati0n.

(4).Assay before furnace :Temperature control is an important and complex process during cast steel ball production. Different tapping temperature and heat temperature are sensitively reflected in the quality of the products. It is requested to master the proper pouring temperature ,mold temperature ,so that can make sure the products achieve a good state of body tissue during the transition from Liquid to solid states.

(5).Mould forming: Pouring when the molten iron temperature difference between molten iron and the molds. In this way ,the ball can achieve internal organization of grain refinement and be more dense .Meanwhile ,the carbide is radically arranged ,and such Carbide is embedded in the matrix again during grinidng process, forming harde layer continuously .So that the hardness and thoughness is maintained to a reasonable.

(6).Heat treatment: We have two sets of heat treatment production line .One is oil quenching, the other is air quenching ,so that the grinding balls can be burring through quenching. And the grinding media has the characters of high hardness ,good thoughness,low wear rate ,low break rate, wear -resistant etc. through tempering .

1.Chemical composition of Long Working Life and Good Material Forging Grinding Media Balls

C | Mn | Si | Cr | Mo | S | P | |||||

Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Max | Max |

0.72 | 0.82 | 0.70 | 1.10 | 0.17 | 0.37 | 0.28 | 0.60 | 0.00 | 0.04 | 0.04 | 0.035 |

2 Hardness of Long Working Life and Good Material Forging Grinding Media Balls

DIA25MM-DIA90MM | DIA110MM-DIA150MM | |

Superficial | 60HRC-65HRC | 55HRC-63HRC |

Volumetric | 60HRC-65HRC | 55HRC-63HRC |

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Use the vibrator to polish the material: the high aluminum porcelain 4cm (with a polishing agent that has an automatic mending function), you go find this polish,

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Because the grinding machine is layer by layer. And the material inside the casting is not completely uniform.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Cast iron has not been done, if it is iron, then in the spray before going through strict pretreatment, the surface can not have a little oil dust

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- 1, gray cast iron: General graphite annealing, to be heat treatment annealing, surface hardening etc.; ductile iron can be various: annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical heat treatment.2. Pouring liquid metal into the casting cavity which adapts to the shape of parts. After cooling and solidification, the casting method is called casting. Castings obtained by casting are called castings. Casting structure design: ensure the working performance and mechanical performance requirements, consider the technical requirements and performance of alloy casting casting casting structure, casting structure design is reasonable or not, the casting quality, productivity and cost has a great influence.3. Heat treatment is a metal hot working process in which the material is in solid state by means of heating, heat preservation and cooling to obtain desired microstructure and properties

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Even distribution is a good thing. Generally, the machining allowance of the casting is uneven.If the processing depends on how your processing techniques have been arranged.In the NC milling plane contour machining, when the rough margin is large, how to deal with.1. Return to the foundry, too large margin improvement.2. Then you can spend more time on it.

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting. It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

1. Manufacturer Overview

| Location | Anshan City, Liaoning Province,China |

| Year Established | 2002 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Domestic Market; South America; Eastern Asia; South Asia; Mid East |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port;Dalian Port;Tianjin Port;Yingkou Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6 - 10 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | 24,400 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | grinding ball,grinding media,casting ball,casting grinding ball |

| Product Price Range | Average |

Send your message to us

Forged Grinding Media Balls Highly Durable Long Lasting

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords