Wear Resistant Grinding Steel Ball with High Hardness Made in China for Mineral Processing

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Reasons to choose us for Wear Resistant Grinding Steel Ball with High Hardness Made in China for Mineral

Processing:

1)State-owned company supplier

2) Excellent reputation

3) timely delivery with satisfactory service

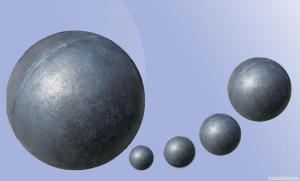

Specifications of Wear Resistant Grinding Steel Ball with High Hardness Made in China for Mineral Processing:

1. professional in grinding ball

2. good wear-resisting, low break

3. high toughness, hardness(60-65 )

Chemical Composition of Wear Resistant Grinding Steel Ball with High Hardness Made in China for Mineral Processing:

1.Type and Chemical Composition | ||||||||

Brand | Grade | C | Mn | Si | Cr | S | P | |

CNBM-1 | 50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | |

CNBM-2 | 60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | |

CNBM -3 | 65Mn | 0.6-0.7 | 0.9-1.2 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | |

CNBM -4 | 75MnCr | 0.70-0.85 | 0.7-0.8 | 0.17-0.37 | 0.2-0.7 | 0.03max | 0.03max | |

CNBM -5 | Rail IronⅠ | 0.5-0.65 | 0.60-1.0 | 0.15-0.37 | 0.25max | 0.04max | 0.04max | |

CNBM -6 | Rail IronⅡ | 0.60-0.8 | 0.90-1.2 | 0.20-0.40 | 0.20-0.8 | 0.07max | 0.03max | |

Weight and Microstructure of Wear Resistant Grinding Steel Ball with High Hardness Made in China for Mineral Processing:

Norminal Diameter | Diametrical Tolerance(mm) | Approx Weight of Single Ball(kg) | Average Number of One MT | Microstructure |

25mm/1'' | +1.5,-0.5 | 0.064 | 15625 | M+B+C (M-Martensite;B-Bainitic;C-Carbide) |

30mm/1.25'' | +1.5,-0.5 | 0.11 | 9090 | |

40mm/1.5'' | +2.0,-1.0 | 0.26 | 3846 | |

50mm/2'' | +2.0,-1.0 | 0.51 | 1961 | |

60mm/2.5'' | +3.0,-2.0 | 0.89 | 1124 | |

70mm/2.75'' | +3.0,-2.0 | 1.4 | 714 | |

80mm/3.25'' | +3.0,-2.0 | 2.1 | 476 | |

90mm/3.5'' | +3.0,-2.0 | 3 | 333 | |

100mm/4'' | +4.0,-3.0 | 4.1 | 244 | |

110mm/4.5'' | +4.0,-3.0 | 5.47 | 283 | |

120mm/4.75 | +4.0,-3.0 | 7.1 | 141 | |

130mm/5'' | +4.0,-3.0 | 9.02 | 111 |

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- According to the requirements of the workpiece annealing, there are many kinds of annealing process specifications, such as full annealing, spheroidizing annealing and stress relieving annealing. Steel the steel quenching is heated to the critical temperature Ac3 (hyposteel) or Ac1 (hypereutectoid steel) above a certain temperature, holding time, so that all or part of 1 Austenitic, then the cooling rate is greater than the critical cooling rate of fast cooling to below Ms (or near Ms isothermal) of martensite the body (or bainite transformation) heat treatment process. Aluminum alloys, copper alloys, titanium alloys, tempered glass and other materials are usually treated by solid solution or heat treatment with rapid cooling process. Tempering is a heat treatment process where the workpiece is hardened and heated to a temperature below AC1, which remains cool for a certain period of time and then cools to room temperature. Tempering generally followed by quenching, the purpose is: (a) to eliminate the residual stress caused by quenching, prevent deformation and cracking; (b) hardness, strength, plasticity and toughness of workpiece is adjusted, to use performance requirements; (c) the size of organization and stability, ensure the accuracy improvement; (D) and to improve the processing performance. Tempering is therefore the last important step in obtaining the desired properties of the workpiece. According to the tempering temperature range, tempering can be divided into low temperature tempering, medium temperature tempering and high temperature tempering. This answer is recommended by the questioner

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: The casting sand is going on

- Dispersed sand inclusion is common on the surface and subcutaneous of steel castings, often concentrated on the outer surface of the upper box and the inner surface of the lower case, and a few of them are inside the cast steel parts.

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: How much is the amount of electrophoretic paint per square meter used in the casting?

- In general, when the final thickness of 15-20 microns, cathode electrophoresis paint can be coated per kilogram of 6-8 square meters, the current general cathode electrophoresis paint for the price of 22 yuan / kg, so the cathodic electrophoresis electrophoresis paint cost at 4 yuan / square meters.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 3, the resonance method is cast on its resonant frequency vibration 1060ndn, to eliminate the residual stress in casting.

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Die die must charge, wood cheap, expensive aluminum mold

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting.

- Q: What's the cause of the choking of the casting?,

- Causes of choking fire:1., casting material in the pouring of gas;

- Q: How can the casting be free of trachoma?

- 3, the gate is not facing sand core, flush sand core, will cause trachoma.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2000 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Domestic Market, South Asia, Southern Europe, Northern Europe, Central America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Balls; Grinding Rods; Grinding Cylpebs. |

| Product Price Range | Average |

Send your message to us

Wear Resistant Grinding Steel Ball with High Hardness Made in China for Mineral Processing

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords