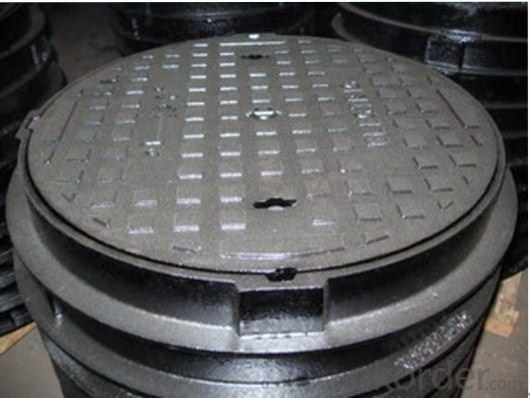

Ductile Iron Manhole Cover EN124 D400

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Wood pallet with iron strap and plastic bag |

| Delivery Detail: | According to client order quantiy |

Specifications

Good Design and Quality

Best Price

Quick Delivery

Best Service

Details of DLP Ductile Iron Manhole Cover for sqaure sets:

1) Manufactured to be BS EN124 Class D400

2) Metarial: ductile iron GJS 500/7

3) Size:

| Item No. | Frame | Cover | Clear opening | Total height | Weight | Mark |

| MSD40 | 400x400 | 324x324 | 290x290 | 75 | 19.00 | SGS |

| MSD50 | 500x500 (495x495) | 424x424 | 390x390 | 100 | 29.00 | SGS |

| MSD55 | 550x550 | 482X482 | 450X450 | 100 | 41.00 | |

| MSD60 | 600x600 | 524x524 | 490x490 | 100 | 43.00 | |

| MSD70 | 700x700 | 634x634 | 600x600 | 100 | 62.00 | |

| MSD80 | 800x800 | 724x724 | 690x690 | 100 | 78.00 | SGS |

| MSD90 | 900x900 | 824x824 | 790x790 | 100 | 110.00 | |

| MSD100 | 1000x1000 | 928x928 | 890x890 | 100 | 150.00 | |

| MSD110 | 1100x1100 | 1034x1034 | 990x990 | 100 | 175.00 | |

| MSD120 | 1200x1200 | 1134x1134 | 1090x1090 | 100 | 208.00 |

4) Corrosion resistent

5) Superior safety performance

6) Processes:

a Automatic machine lines

b Green sand with hand moulding

7) Inscription styles according to client requirements

8) Inspection:

a) Foundry in-house

b) Third party inspection available upon request

9) Packing:

a) Wooden Pallet

d) As per customers' requirements

10) Different accessories are available

11) Quick deliver

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Buffing should be better, to see how your embryo, but a bit difficult

- Q: How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q: Why does the precision casting factory not usually make iron castings?

- Jiangyin Lin Xing stainless steel (precision manufacturing) Co., Ltd. to provide professional precision casting

- Q: What are the factors affecting the machining process of the casting material and structure?

- As for the metallographic structure, usually the finished products after casting are treated by heat treatment. The mechanical properties of the carbon steel after heat treatment (quenching and tempering) are detected. The stainless steels are treated by heat treatment (solid solution, etc.) and the metallographic structure is analyzedThere is a lot of talk and a bit of confusionIf you have a specific brand, you can search for Baidu or buy tools

- Q: What are the casting parts processing engineering?

- Among them, special casting has metal mould casting, pressure casting, low pressure casting, lost wax casting (also known as precision casting), shell casting, lost foam casting, centrifugal casting, continuous casting, V casting, and clay casting

- Q: Casting parts have poor surface finish. What sand is used to make them?

- Manual coal dust, clay sand is a little worse. Mechanical styling is not bad either.

- Q: Why do casting parts have air holes?

- First, from the source, tools, raw material drying, in the process of melting into the reaction gas, another influence is pouring process, such as high temperature solidification gas dissolved too much after not excluded. The method can adjust the pouring temperature properly, control the source of gas (drying and controlling the inoculant, especially the content of magnesium), and add cooling iron to change the solidification mode. It depends on what kind of casting you are. You can't make it clear at once. And molding sand relationship is mainly water content and permeability, brush coating resin content.

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing refers to making the first sample to confirm to the customer

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- Phosphating. But it's not necessary. Because casting parts have strong corrosion resistance.

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting.

Send your message to us

Ductile Iron Manhole Cover EN124 D400

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords