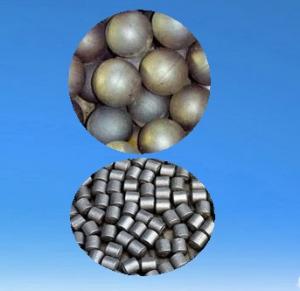

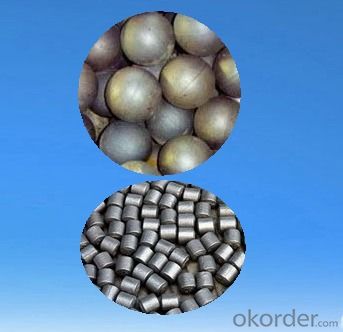

Rolling Steel Grinding Ball with Well Abrasive Resistance High Quality for Mineral Processing and Cement

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features and Advantages of Rolling Steel Grinding Ball with Well Abrasive Resistance High Quality for Mineral

Processing and Cement:

1) High hardness: It has high hardness: surface hardness can reach 55-67 HRC, volume hardness 56-64 HRC

2) High Impact toughness: impact toughness is more than 15 J / cm2.

3) Low Broken rate: peel fragmentation resistance property of over 20000 times. The actual breakage rate is less than 1% and close to 0.

4) Size: Our products range from 20mm to 150mm, 1 inch to 6 inch, and we can also offer all size of products according to clients’ demand.

Chemical Elements of Rolling Steel Grinding Ball with Well Abrasive Resistance High Quality for Mineral

Processing and Cement:

Type | Name | C | Mn | Si | Cr | S | P |

CMAX-F01 | 20MN | 0.12-0.22 | 1.00-1.60 | 0.60-0.80 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-F02 | 45# | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-F03 | 50MN | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-F04 | 60MN | 0.57-.0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-F05 | 65MN | 0.60-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-F06 | B2 | 0.70-0.85 | 0.70-0.80 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.035 |

Specification and Hardness of Rolling Steel Grinding Ball with Well Abrasive Resistance High Quality for Mineral

Processing and Cement:

Type | Name | Impact Test AK.J/cm2 | Endurance Test Times(5m) | Dia 25mm-60mm | Dia 70mm-100mm | ||

Surface | Core | Surface | Core | ||||

CMAX-F01 | 20MN | ≥12 | ≥10000 | ≥42 | ≥48 | ≥40 | ≥45 |

CMAX-F02 | 45# | ≥12 | ≥10000 | ≥52 | ≥48 | ≥53 | ≥46 |

CMAX-F03 | 50MN | ≥12 | ≥10000 | ≥56 | ≥50 | ≥55 | ≥50 |

CMAX-F04 | 60MN | ≥13 | ≥12000 | ≥58 | ≥52 | ≥58 | ≥50 |

CMAX-F05 | 65MN | ≥15 | ≥12000 | ≥62 | ≥54 | ≥58 | ≥52 |

CMAX-F06 | B2 | ≥15 | ≥12000 | ≥62 | ≥55 | ≥58 | ≥52 |

- Q: What are the casting parts used to test shrinkage holes?

- 1. anatomy. It is easy to slack off by sawing and machining.

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- 4, the performance requirements of the steel: whether castings or welding parts, there may be quality defects, but the casting will generally be worse than the weldment.You should be able to make a choice in the end.

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Casting rough drawings generally no processing symbols, processing drawings indispensable is processing symbols!

- Q: Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- Service performance: heat conductivity, friction reduction, shock absorption, heat resistance and corrosion resistanceTo compare these properties, it depends on the specific material, structure, and use of the parts. Otherwise, there is no comparisonS

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: Why should pig iron be used in casting?

- 1, in the absence of special requirements, the most important thing is that the price is cheap.2, pig iron castings quenching process requirements are not high. You can do it by hand.3, pig iron casting hardness is very large, can meet many requirements.4, pig iron castings, high temperature resistance is relatively strong. Like stoves are pig iron castings.5, pig iron casting plasticity is very bad, but in some experiments, but use this weakness to improve the sensitivity of the experiment.Wait

- Q: Heat treatment process and purpose of casting parts

- Natural aging (also known as Chang Hua): lost in the open, the sun and rain, can have experienced years of wind and frost.

- Q: How can the casting be free of trachoma?

- Measures for the prevention of trachoma in castings:1, sand compaction to high, paint two times;

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2000 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Domestic Market, South Asia, Southern Europe, Northern Europe, Central America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Balls; Grinding Rods; Grinding Cylpebs. |

| Product Price Range | Average |

Send your message to us

Rolling Steel Grinding Ball with Well Abrasive Resistance High Quality for Mineral Processing and Cement

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords