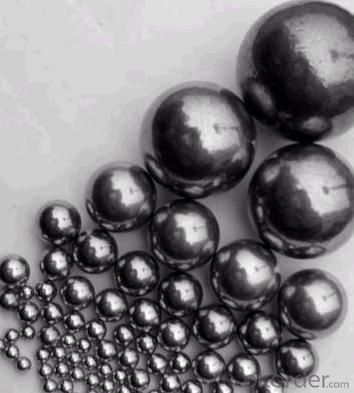

HIGH CARBON STEEL BALL WITH BEST QUALITY & LOWEST PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Steel Balls

2) Grade: G100-G1000

3) Hardness: HRC55-63.

4) General Application:

Bearings, Automotive, Castors, Locks, Drawer Slides, Welding, Capabilities decorative, bicycle parts, light-duty, hardware, toy and etc.

5) Certificate: ISO-9001, TS-16949, ISO14001

6)Standard: AFBMA10 1989, DIN5401, GB308-2002, JIS B1501 1988.

Balls of this type are generally used in applications where there are only moderate loads and slow rotating parts, for example Castors, Conveyors and non-precision bearings. There is a significant price saving compared to High Carbon Chrome balls.

The main feature of this type of ball is the Carburised case with a soft core giving resistance to shock loads, good load carrying ability and excellent resistance to surface wear.

International Equivalents

AISI 1065, 1085 JIS SWRM 12, EN32 ASTM A/29, Wks 1.0010;

1010/1015 carbon steel ball is a ball very common, with low price and high hardness characteristics, more extensive use. Commonly used in bicycles, bearings, pulleys, slide, crafts, shelves, universal ball, bags, small hardware pieces, also be used to grind other media.

1085 high carbon steel balls are widely used in bicycles, bearings, pulleys, slide, crafts, shelves, universal ball, bags, small hardware pieces, also be used to grind other media.

1065 carbon steel balls are widely used in auto parts, aviation, aerospace, hardware tools, chemical industry. As follows: Crafts, bearings, pulleys, then columns, and so on.

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- The surface can be improved by a little more than Xiasha

- Q: Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- The first to ask, such as casting end cover, bed and other products, is to put the iron melting and casting againThe two question, their casting castings manufacturers than to buy professional casting factory production, production quality more security professional.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Single for this problem, the direct casting out of course good. But many times because of the limitations of the process, so we choose the post-processing hole

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- According to different casting process and parts materials, each has relevant standards, can be found online;

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

- Q: The difference between sheet metal and casting parts

- Commonly used in machine tools casting material is gray cast iron, casting bearing alloys can also be.

- Q: ZGMn13 casting parts processing, with what knife head good?

- its surface wear resistance is high; the two is with the gradual wear of surface hardening, the hardening layer is continuously formed new if you have suggestions, processing, plasma cutting or flame cutting try

- Q: How can the casting be free of trachoma?

- 3, the gate is not facing sand core, flush sand core, will cause trachoma.

Send your message to us

HIGH CARBON STEEL BALL WITH BEST QUALITY & LOWEST PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches