HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

1. Product Performance for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

a).Hardness:50-65

b).Chromium percentage:0.25MAX

c).Heat treatment:cycles

d).Impact test>12AK.J/CM2

e).Endurance test times>=10000

f).Characteristic: a)unbreakable; b)even hardness; c)high impact value; d)good wear resistance; e) high combined efficiency of grinding mill

g).Productive technology: forging /hot-rolling

h).Packing:container bag:1000Kgs/Container Bag, Steel Drums: 850-900Kgs/Drum

i).Application : a) Mines b) Cement plants; c) Power stations; d) Chemical industry; e) other grinding industries.

j).Certificates: SGS/TUV/ ISO9001:2008

k). Microstructure: M+B+C(M-Martensite;B-Bainitic;C-Carbide)

2. Chemical Composition for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

Name | Material | C | Mn | Si | Cr | S | P |

CMAX-1 | 50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-2 | 60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-3 | 65Mn | 0.60-0.70 | 0.90-1.2 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-4 | B2 | 0.70-0.85 | 0.70-0.80 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.03 |

CMAX-5 | 75SiMn | 0.70-0.90 | 0.70-1.20 | 0.4-0.8 | ≤0.25 | ≤0.03 | ≤0.03 |

CMAX-6 | Wear-resistant Alloy | 0.50-0.65 | 0.4-1.0 | 1.4-1.8 | 0.9-1.2 | ≤0.03 | ≤0.03 |

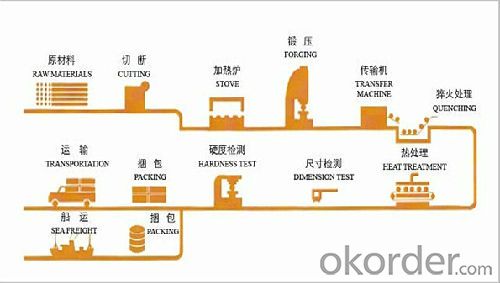

3. Production Process for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

3. Testing Methods for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

3. Packing Details for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- The aim is to make the grain fine and distribute the carbide evenly. The difference between normalizing and annealing is that normalizing cooling rate is slightly faster than annealing cooling rate, so normalizing structure is finer than annealing structure, and its mechanical properties are also improved. In addition, normalizing furnace cooling does not occupy equipment and has higher productivity. Therefore, normalizing may be used instead of annealing as much as possible. The main application areas of normalizing are as follows: for low carbon steel, after normalizing, the hardness is slightly higher than that of annealing, and the toughness is better. It can be used as the pretreatment of cutting. Used for medium carbon steel, instead of quenching and tempering, as the final heat treatment, or as an induction heating method before surface hardening. Used for tool steel, bearing steel, carburizing steel, etc., it can eliminate or restrain the formation of network carbide, so as to obtain the good organization of spheroidizing annealing. For cast steel, the microstructure can be refined and the machinability can be improved. Used for large forgings, which can be used as final heat treatment, so as to avoid larger cracking tendency during quenching.

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- Annealing is needed to eliminate stress and refine grain

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- If it is not directly cast hole hole, later processing, large pores may be directly cast out,

- Q: Casting parts have poor surface finish. What sand is used to make them?

- Manual coal dust, clay sand is a little worse. Mechanical styling is not bad either.

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: Why do casting parts have air holes?

- There are many reasons for casting porosity, mainly due to:1. smelting process is unreasonable, metal liquid absorbs more gas;2. the gas in the mold invades the metal liquid;3. from the mold is more water brush, core dry;4. the casting has poor ventilation;5. ladle tools are not dry.Wait。

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- There is YW1 best, if not using YG6X, YG8 is ok!The speed should not be high, the greater the diameter, the lower the speed! For example, a diameter of 100 mm, speed is not greater than 80 rpm, each point is good!The main tool is the front angle to be larger, more than 6 degrees, and the groove should be wider and larger to reduce the cutting resistance! When the rear angle is properly reduced and the strength is increased, it is recommended to take 3 degrees.The main components are: spindle box, exchange gear box, feed box, slide box, tool post, tail frame, light bar, lead screw, bed, foot and cooling device.Spindle box: also known as the headstock, it is the main task of the rotary motion of the main motor came through the transmission mechanism of a series of positive and negative spindle to be required two different steering speed, the spindle box gives impetus to the movement of the box. Medium spindle is the key part of lathe. The stability of the spindle on the bearing directly affects the quality of the workpiece. Once the rotation accuracy of the main shaft is reduced, the value of the machine tool will be lowered.

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- (3) to prevent generating white grey cast iron, in addition to taking measures from the process, must make the wall thickness is not too thin (some sources indicate that the corner wall thickness above 15mm, metal type casting must be in the corner, for Aluminum Alloy, magnesium alloy casting casting casting Create fillet should not be less than 3-4m, for casting round cast iron, copper alloy mould casting can see table 1.1-32 selection; (5) because of the metal and the core without let, for the convenience of the casting is taken out and the draw out type, slope casting casting should be suitably large than sand casting metal casting. General 30%-50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction and metal surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal castings the type should be given greater inclination, all kinds of metal type alloy casting casting casting.

- Q: ZGMn13 casting parts processing, with what knife head good?

- The ZGMn13 itself is not have processing, if only the processing point, sharpening, ordinary can, if the processing area is relatively large, ZGMn13 external impact load is bigger,

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords