Best-quality High Chrome Casting Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

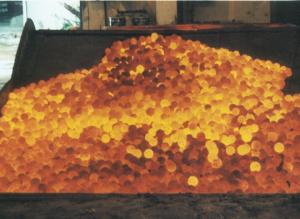

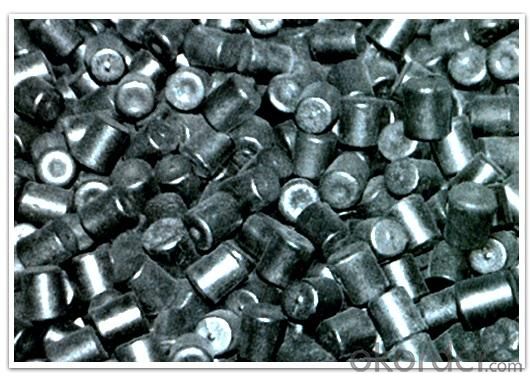

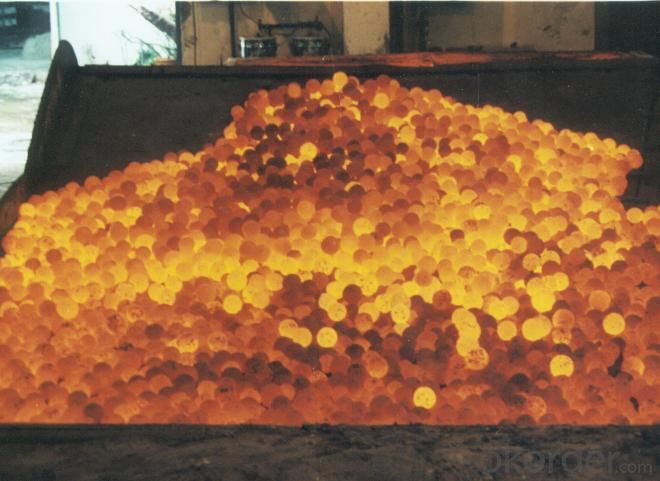

General Information of Best-quality High Chrome Casting Bars

CMAX products have excellent surface finish, high load carrying capacity, high intensity, high hardness, high wear ability, high temperature resistance, impact resistance, low damage percentage and so many other features. CMAX products can help corporations to promote production, reduce production cost, reduce labor intensity of the workers.

Specifications of Best-quality High Chrome Casting Bars

1)High hardness&low breakage

2)Good wear resistance

3)Reasonnable price

Application of Best-quality High Chrome Casting Bars

CMAX High Chrome Casting Bars are widely used in powder preparation and super finishing for the devices of cement, building materials, metallurgy, thermal power plant, ceramics, refractories and the other industries.

Our company has success in the products due to their cost-effectiveness, excellent strength and resistant properties. We also have experience in casting bars application and would like to assist you in product selection, system design, and installation techniques.

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: What's the effect of casting copper?

- Riga. Copper is copper components, promote the graphitization of the copper element, make dense tissue, and to refine and improve the uniform distribution of graphite, which can reduce the chilling tendency of the cast iron, but also can promote the formation of pearlite, has a favorable effect on the section sensitivity. Copper has the tendency to strengthen cast iron, ferrite and pearlite, so it can increase the strength of cast iron. The tensile strength and bending strength of cast iron almost increase with the amount of copper in it, especially in low carbon cast iron.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Usually after rusting,Did you peel it?If it isNeed to do film processingIf notPlease look for the coating factoryBetter paint (such as epoxy ester, etc.)

- Q: Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good.

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Single for this problem, the direct casting out of course good. But many times because of the limitations of the process, so we choose the post-processing hole

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- What you say is the difference between rough drawing and processing drawingThere must be a difference between the rough drawings and the rough ones

- Q: Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- The performance is too extensive, I think the following several people all fall into the erroneous zone directly, the performance includes a series of aspects:Mechanical properties: tensile strength, yield strength, elongation and contraction ratio of section and impact toughness after etc.

- Q: What's the cause of the choking of the casting?,

- 3. when casting the environment is humid, sand mold has not removed the moisture, when the casting, the moisture instantaneous transforms into the steam, causes the blowhole

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

1. Manufacturer Overview

| Location | Anhui, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 5 million |

| Main Markets | Mid East; Eastern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 21% - 50% |

| No.of Employees in Trade Department | 31-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Best-quality High Chrome Casting Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords