Ductile Iron Manhole Cover B125

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 18 Tons m.t.

- Supply Capability:

- 500 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

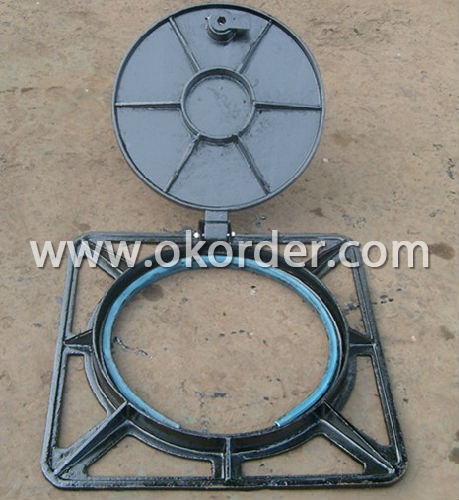

Features of DI Manhole Cover B125:

1. High load rating and strength

v Similar hard property as cast iron, while have a overwhelming advantage on stretch recovery.

v Less noise and lower vibration transmissions.

2. Against theft and safety options

v Zero theft value, reducing potential accident and further maintenance cost caused by thieves.

v Surface anti-slip thread guarantees safe road condition even in extreme weather.

v Locks are available as an option molded into the cover to improve security rate.

v Non-electricity conduction and non-heat conduction.

3. Lightweight

v Compared with cast iron manhole covers, composited covers are 50% lighter.

v Lightweight allows more loading per vehicle, more convenient transportation and economical saving.

v Allows a safer working condition, which a SINGLE worker is enough when installation without risk of injury.

4. Durable service life.

v More than 30 years service life without crack and color fading, comparing to 5 years of cast iron.

v Anti corrosion,water, dust and pets tight, well sealed prevent poisonous gas leaking out.

v Without displacement, freely radio signal passing.

v Higher and lower temperature tolerance with the range -40°C-200°C.

v Wear indicators available when thread depth is in a danger value.

5. Free design

v Much more clear resolution ratio of surface design than cast iron or BMC.

6. Carbon footprint saving and environmental care.

v Lower embedded energy carbon emission and during manufacturing process than cast iron covers.

Packaging of DI Manhole Cover B125:

Metal band, plastic, wooden pallet. As per customers' requirements

Delivery Detail of DI Manhole Cover B125:

15 days after receiving the deposit.

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Because the grinding machine is layer by layer. And the material inside the casting is not completely uniform.

- Q: The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q: What are the requirements for casting steel castings?

- 2, the plane should be placed on the following.3, thin parts should be placed below.

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- Annealing is needed to eliminate stress and refine grain

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What is the difference between forging parts and casting parts?

- The casting parts are low in cost and short in production period. Because the molten iron has good flow properties, complex shapes can be formed. But because there may be sand holes, pores, shrinkage holes and other defects, the quality is unstable, easy to produce many defects, mechanical properties are not forged well, thus affecting the service life.

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 1.5 Million |

| Main Markets | Mid East, Africa, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 60% |

| No.of Employees in Trade Department | 300 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 15,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ductile Iron Manhole Cover B125

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 18 Tons m.t.

- Supply Capability:

- 500 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords