Ductile Iron Pipe ISO2531 / EN545 / EN598 K9 DN300

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Ductile Iron Pipe Description :

DI pipe fittings are manufactured according to ISO 2531 or BS EN545 or BS4772 FOR POTABLE WATER ,internal is cement lining or wet epoxy coating;External is zinc plus bitumen or wet epoxy coating. We also manufacture ductile iron fittings with fusion bonded epoxy both inside and outside. All the producets are sutible to water pipes fields.We have passed ISO9001,ISO14001,OHSMS18001 certificate.

2.Main Features of the Ductile Iron Pipe:

•High yield strength

•High tensile Strength

•High corrosion resistance

•Pressure Resistence

•Satisfy the highest hygienic standards

1. Material: Ductile iron grade 500-7/ 450-10 in accordance with ISO1083

2. Standard: ISO 2531, EN545, EN598, ANSI, AWWA

3. Certificate: ISO9001, ISO14001, SGS, NSF, WRAS

4. Test: In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test

5. External coating: Zinc + Bitumen, conform to ISO8179

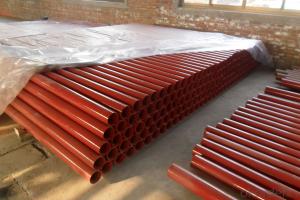

3.Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

Place of Origin: China (Mainland)

Model Number: DN80-1600

Length: 6M/5.7M/NEGOTIATED

Standard: ISO2531 / EN545

Application: Potable/Sewage Water

Diameter: DN80-1600

Shape: Round

Hardness: 230

Pipe Wall Thickness: standerd

Material: Ductile Iron

water ductile iron pipe: SO2531 / EN545 DI pipe

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining.These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: How does ductile iron pipe perform in areas with high soil settlement?

- Ductile iron pipes perform well in areas with high soil settlement due to their inherent strength and flexibility. Their ability to withstand soil movement and settlement helps prevent pipe damage or failure. Additionally, ductile iron pipes are designed with joints that allow for some movement, further reducing the risk of cracks or breaks. Overall, ductile iron pipes are a reliable choice for areas prone to high soil settlement.

- Q: Are ductile iron pipes suitable for use in chemical storage tanks?

- Chemical storage tanks cannot be made with ductile iron pipes since they are not able to resist corrosion caused by different chemicals. While ductile iron pipes possess exceptional mechanical properties, such as high tensile strength and impact resistance, they are not equipped to handle the corrosive nature of chemicals. To ensure the safety and integrity of the tank, materials that can withstand the corrosive properties of the stored chemicals, such as fiberglass-reinforced plastic (FRP), stainless steel, or high-density polyethylene (HDPE), are commonly used for chemical storage tanks. It is of utmost importance to carefully choose the appropriate material for chemical storage tanks in order to prevent leaks, contamination, and potential hazards.

- Q: What are the different pressure classes available for ductile iron pipe?

- The different pressure classes available for ductile iron pipe include Class 100, Class 150, Class 200, Class 250, Class 300, Class 350, and Class 400.

- Q: An urban infrastructure construction, water supply pipe is ductile iron pipe and PE pipe, thank you

- From the tightness and corrosion resistance, ductile pipe sealing better after installation, but also can improve the corrosion resistance of corrosion protection through a variety of means; from the hydraulic performance, because ductile pipe specifications generally refers to the inner diameter of PE pipe diameter specifications generally refers to the same specifications, because under the condition of ductile pipe can achieve more runoff large; from the installation and maintenance cost, ductile pipe have more favorable price.

- Q: Are ductile iron pipes resistant to biogenic sulfide corrosion?

- Ductile iron pipes are known for their general resistance to biogenic sulfide corrosion. Biogenic sulfide corrosion is caused by the reaction between hydrogen sulfide gas, which is produced when organic matter decays, and metallic surfaces. However, ductile iron pipes have a protective layer called the cement mortar lining, which acts as a barrier against corrosive agents. This lining effectively resists the corrosive effects of biogenic sulfide, making ductile iron pipes a suitable choice for applications where this type of corrosion is a concern. In addition, the strength and durability of ductile iron pipes further contribute to their ability to resist biogenic sulfide corrosion.

- Q: What is the maximum temperature that ductile iron pipe can handle?

- The maximum temperature that ductile iron pipe can handle typically ranges between 350-400 degrees Fahrenheit.

- Q: DN1800 can the length of ductile iron pipes be several meters? What is the total weight?

- Ductile iron pipe is a kind of cast iron pipe.

- Q: Can centrifugal cast iron pipe be galvanized or coated with asphalt which is good for corrosion prevention?

- 1, outdoor grounding of anti-corrosion, we must consider the contact resistance, so it is recommended not to use asphalt, and do not use anti-corrosion paint, preferably galvanized anti-corrosion.2, asphalt anti-corrosion paint has good water resistance, moisture resistance, corrosion resistance. Acid and alkali resistance, salt fog resistance, atmospheric exposure and so on. The utility model is suitable for coating internal and external surfaces of various containers and machinery, underground steel structures and underground pipelines for moisture proof, water resistance and corrosion prevention. The utility model is also suitable for repairing water cracks in houses.3, anticorrosive paint is used in the surface of the object, can be used to protect the interior of the object without corrosion of a kind of paint. It is one of the more commonly used than paint anti-corrosion paint in industrial construction, widely used in aviation, shipbuilding, chemical, oil pipelines, steel structures, bridges, oil rigs and other fields, by the vast number of manufacturers favor building.

- Q: What are the typical joint restraint systems used in ductile iron pipes?

- The typical joint restraint systems used in ductile iron pipes include mechanical joint restraints, push-on joint restraints, and restrained joint systems. 1. Mechanical Joint Restraints: These systems use mechanical devices to secure the pipe joints. The most common type of mechanical joint restraint is the gland-type restraint, which consists of a gland and a follower. The gland is placed over the pipe joint and tightened using bolts, creating a tight seal and preventing movement. 2. Push-On Joint Restraints: Push-on joint restraints utilize a rubber gasket to create a watertight seal between the pipe sections. These restraints do not require any additional devices or bolts to secure the joint. The gasket creates enough friction and compression to prevent the pipe from separating. 3. Restrained Joint Systems: Restrained joint systems provide a high level of joint integrity and resistance to longitudinal movement. These systems typically use a combination of mechanical joint restraints and push-on joint restraints. They may also incorporate additional elements such as harnesses, rods, or wedges to provide extra support and prevent joint separation. It is important to note that the specific joint restraint system used in ductile iron pipes may vary depending on the application, pipe diameter, and operating conditions. The selection of the appropriate joint restraint system is crucial to ensure the structural integrity and longevity of the pipeline.

- Q: How are ductile iron pipes protected from external damage?

- Ductile iron pipes are protected from external damage through the application of protective coatings. These coatings act as a barrier, shielding the pipes from corrosion and other forms of external damage. Additionally, the pipes may be encased in concrete or installed in a casing pipe to provide further protection against external forces and impacts.

Send your message to us

Ductile Iron Pipe ISO2531 / EN545 / EN598 K9 DN300

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords