Ductile Iron Pipe Mechnical Joint K Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meter m

- Supply Capability:

- 250000 Ton Per Year m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction & Specifications of Ductile Iron Pipe Mechnical Joint K Type.

Pipes according to ISO2531/EN545

K Type joint

Size: DN80-DN2000

Effective length: 6m/pc or 5.7m/pc or 5.5m/pc

Internal lining: cement mortar lining comply with ISO4179

External coating: sprayed metallic Zinc coating (min.130g/m2) according to ISO8179 + bitumen painting (min.70μm) according to BS3416.

Gasket: Matched 100% natural rubber gasket in accordance with ISO4633.

Standard Wall Thickness of Ductile Iron Pipe Mechnical Joint K Type.

|

Nominal Diameter |

Wall Thickness(mm) | ||||||

|

DN(mm) |

Pipe |

Fittings | |||||

|

Class C |

K8 |

K9 |

K10 |

K12 |

K12 |

K14 | |

|

80 |

4.4 |

6 |

6 |

7 |

8.1 | ||

|

100 |

4.4 |

6.1 |

7.2 |

8.4 | |||

|

125 |

4.5 |

6.3 |

7.5 |

8.8 | |||

|

150 |

4.5 |

6.3 |

7.8 |

9.1 | |||

|

200 |

4.7 |

6.4 |

8.4 |

9.8 | |||

|

250 |

5.5 |

6.8 |

7.5 |

9 |

9 |

10.5 | |

|

300 |

6.2 |

6.4 |

7.2 |

8 |

9.6 |

9.6 |

11.2 |

|

350 |

6.3 |

6.8 |

7.7 |

8.5 |

10.2 |

10.2 |

11.9 |

|

400 |

6.5 |

7.2 |

8.1 |

9 |

10.8 |

10.8 |

12.6 |

|

450 |

6.9 |

7.6 |

8.6 |

9.5 |

11.4 |

11.4 |

13.3 |

|

500 |

7.5 |

8 |

9 |

10 |

12 |

12 |

14 |

|

600 |

8.7 |

8.8 |

9.9 |

11 |

13.2 |

13.2 |

15.4 |

|

700 |

8.6 |

9.6 |

10.8 |

12 |

14.4 |

14.4 |

16.8 |

|

800 |

9.6 |

10.4 |

11.7 |

13 |

15.6 |

15.6 |

18.2 |

|

900 |

11.6 |

11.2 |

12.6 |

14 |

16.8 |

16.8 |

19.6 |

|

1000 |

12.6 |

12 |

13.5 |

15 |

18 |

18 |

21 |

|

1200 |

13.6 |

13.6 |

15.3 |

17 |

20.4 |

20.4 |

22.8 |

|

1400 |

15.7 |

15.2 |

17.1 |

19 |

22.8 |

22.8 |

26.6 |

|

1500 |

16.7 |

16 |

18 |

20 |

24 |

24 |

31 |

|

1600 |

17.7 |

16.8 |

18.9 |

21 |

25.2 |

25.2 |

29.4 |

|

1800 |

19.7 |

18.4 |

20.7 |

23 |

27.6 |

27.6 |

32.2 |

|

2000 |

21.8 |

20 |

22.5 |

25 |

30 |

30 |

35 |

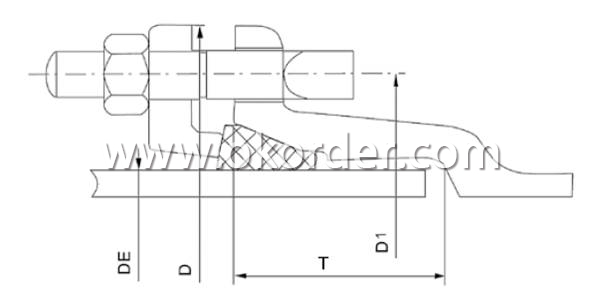

Mechnical Joint of Ductile Iron Pipe Mechnical Joint K Type.

|

Nominal Diameter(DN) |

mm |

Holes No. | |||

|

DE |

D1 |

D |

T | ||

|

100 |

118 |

186 |

232 |

80 |

4 |

|

150 |

170 |

241 |

287 |

80 |

6 |

|

200 |

222 |

292 |

338 |

80 |

6 |

|

250 |

274 |

348 |

394 |

80 |

8 |

|

300 |

326 |

399 |

445 |

110 |

8 |

|

350 |

378 |

458 |

504 |

110 |

10 |

|

400 |

429 |

512 |

558 |

110 |

12 |

|

500 |

532 |

618 |

664 |

110 |

14 |

|

600 |

635 |

725 |

771 |

110 |

14 |

|

700 |

738 |

839 |

893 |

120 |

16 |

|

800 |

842 |

942 |

996 |

120 |

20 |

|

900 |

945 |

1052 |

1118 |

120 |

20 |

|

1000 |

1048 |

1160 |

1226 |

130 |

20 |

|

1200 |

1255 |

1372 |

1438 |

130 |

28 |

|

1400 |

1462 |

1591 |

1657 |

130 |

28 |

|

1600 |

1668 |

1790 |

1856 |

160 |

30 |

|

1800 |

1675 |

1996 |

2062 |

170 |

34 |

|

2000 |

2082 |

2216 |

2282 |

180 |

36 |

Production Flow of Ductile Iron Pipe Mechnical Joint K Type.

Quality raw materials-Molten iron modulation and spheroidizing-Molten iron quality control-centrifugal casting-annealing treatment-performance test-Zinc spraying-hydrostatic testing-cement mortar lining-asphalt spreader-Final inspection packaging warehousing.

Packing and Transportation of Ductile Iron Pipe Mechnical Joint K Type.

Hoisting

Take precaution of handling pipe with steel cable, hoisting belts and specialized rigging avoiding from pipe's rocking. While using steel cable, single cable is not admitted, for the purpose of protecting outer anti-corrosion layer, steel cable should be packed by rubber or other similar material. While using hook, it also should be covered with rubber or other similar material for protecting cement lining layer. Especially for pipe with relative large diameter, hook should be mounted a gasket with same shape as internal diameter of pipes while handling. It is not available fixing hook on the steel belts or socket side and spigot side of pipe while handling pipes in bundle.

Transportation

Put two pieces or more woods on the platform of the vehicle while transporting, pipes are laid on the wood and fixed by wedge. The part over the vehicle body should not be more than 1/4 of overall length of pipe. If pipes are piled up more than one layer, each layer of pipes should reverse, and buffering rubber or gasket should be put on the space between two layers of pipes, at last pipes are fixed up with steel cable and buffering gasket. Check often if pipes can fall out during conveying, and check if stop wedge is not hard up. The vehicle should slow down on the uneven road or while swerving.

Storage

Under pipes there should be put wedge or crosstie while stacking pipes, and socket and spigot of pipes should be interleaved and on the stop wedge in cast of pipe's rolling. Uneven and serious polluted ground, or slope and marshy are not available.

Pictures Show of Ductile Iron Pipe Mechnical Joint K Type.

If you have other question about our products, please feel free to consult us directly.

- Q: How are ductile iron pipes manufactured?

- Ductile iron pipes are produced using a technique called centrifugal casting, which employs a spinning mold. The process commences with the selection and preparation of top-notch ductile iron, a form of cast iron containing small quantities of magnesium to enhance its strength and ductility. Initially, the ductile iron is melted in a furnace at exceedingly high temperatures. Once the molten iron attains the desired temperature, it is poured into a rotating mold. Shaped like a pipe, the mold spins at a high speed, ensuring even distribution of the molten iron along its inner surface. While the mold spins, the molten iron cools and solidifies against the mold walls. This swift cooling leads to the formation of a fine-grained structure, thereby augmenting the mechanical properties of the pipe, including its strength and durability. The spinning mold continues to rotate until the pipe solidifies completely, typically within a few minutes. Upon solidification, the pipe is extracted from the mold and any excess material, referred to as the "skin," is eliminated. Typically, machining or grinding is employed to remove the skin, achieving the desired dimensions and surface finish. Subsequently, the pipe undergoes heat treatment to further enhance its mechanical properties and alleviate internal stresses. After the completion of heat treatment, the pipe undergoes a thorough inspection to identify any defects or imperfections. This inspection encompasses visual examinations, non-destructive testing methods, and pressure testing to ensure compliance with the required specifications and standards. If any defects are detected, the severity of the issue determines whether the pipe undergoes repair or is rejected. Lastly, the pipes are coated with a protective layer to prevent corrosion and extend their lifespan. This protective coating can be applied through various methods, such as cement mortar lining, epoxy coating, or zinc coating. In summary, the manufacturing process of ductile iron pipes encompasses iron melting, centrifugal casting, cooling, skin removal, heat treatment, inspection, and coating. This process guarantees the production of high-quality pipes characterized by exceptional strength, durability, and resistance to corrosion.

- Q: Can ductile iron pipes be used for irrigation systems?

- Yes, ductile iron pipes can be used for irrigation systems. Ductile iron pipes have excellent strength and durability, making them suitable for a variety of applications, including irrigation. These pipes are resistant to corrosion and have a long lifespan, ensuring that they can withstand the harsh conditions often associated with irrigation systems. Additionally, ductile iron pipes have a smooth interior surface, which allows for efficient water flow and reduced friction loss. This makes them ideal for transporting water over long distances, ensuring proper irrigation of crops or landscapes. Overall, ductile iron pipes are a reliable and cost-effective choice for irrigation systems.

- Q: Can ductile iron pipes be used for underground irrigation systems?

- Yes, ductile iron pipes can be used for underground irrigation systems. Ductile iron is a strong and durable material that is resistant to corrosion and can withstand the pressure and load requirements of irrigation systems. It is commonly used in underground applications due to its longevity and reliability.

- Q: Is ductile iron pipe breakable?

- The ductile iron pipe has many uses in our city construction, for our city water supply, gas supply and so on. But ductile iron pipes are also very useful in sewage disposal. As we all know, ductile iron pipe has many excellent properties, such as high strength, corrosion resistance, high pressure resistance, low accident rate, long service life and Gao Yanshen rate. It is an excellent water supply pipe.

- Q: Are ductile iron pipes more expensive than other pipe materials?

- The cost of ductile iron pipes may be higher than some other pipe materials, depending on various factors. Ductile iron pipes are renowned for their durability, strength, and resistance to corrosion, making them a wise long-term investment. However, compared to materials such as PVC or HDPE, the initial cost of ductile iron pipes can be higher. Furthermore, the installation process of ductile iron pipes may necessitate more labor and specialized equipment, thereby increasing the overall expense. Nevertheless, it is crucial to consider specific project requirements, including the environment, expected lifespan, and required pressure ratings, in order to accurately assess the cost-effectiveness of ductile iron pipes in relation to other pipe materials.

- Q: How do ductile iron pipes handle cyclic loading in offshore applications?

- Ductile iron pipes possess remarkable strength and durability, rendering them suitable for a wide range of applications, including offshore usage. When it comes to dealing with cyclic loading in offshore settings, ductile iron pipes boast various characteristics that contribute to their exceptional performance. To begin with, ductile iron pipes demonstrate a high resistance to fatigue failure. Fatigue failure occurs when a material undergoes repeated stress cycles, leading to the initiation and propagation of cracks over time. Ductile iron pipes are specifically designed to endure cyclic loading without compromising their structural integrity. This is made possible by their inherent ductility and ability to effectively absorb and distribute stress. Furthermore, ductile iron pipes exhibit outstanding impact resistance. Offshore environments are prone to dynamic and unpredictable forces, such as waves and currents, which can exert sudden and intense loads on the pipes. The superior impact resistance of ductile iron allows it to withstand these forces without experiencing deformation or fractures, ensuring that the pipes remain intact and fully functional. Moreover, ductile iron pipes possess a unique microstructure that enables them to resist corrosion. Offshore applications expose pipes to harsh environmental conditions, including saltwater, which can accelerate the corrosion process. However, the protective graphite matrix present in ductile iron pipes acts as a barrier, preventing corrosive agents from reaching the underlying metal. As a result, the service life of the pipes is significantly prolonged. Additionally, ductile iron pipes have a high load-carrying capacity. In offshore applications, pipes often need to support heavy loads, such as those exerted by equipment, structures, or seabed settlements. The exceptional strength of ductile iron enables it to effectively bear these loads, ensuring the structural integrity and stability of the entire system. Lastly, ductile iron pipes offer ease of installation and maintenance. Their lightweight nature makes them easier to handle and transport during offshore operations. Furthermore, their corrosion resistance reduces the need for frequent maintenance, minimizing downtime and reducing the costs associated with repairs and replacements. In conclusion, ductile iron pipes exhibit excellent performance when it comes to handling cyclic loading in offshore applications. Their resistance to fatigue failure, impact resistance, corrosion resistance, high load-carrying capacity, and ease of installation and maintenance make them a dependable and efficient choice for offshore environments.

- Q: The difference between spheroidal graphite cast iron pipe and HDPE water supply pipe

- Because the HDPE pipe flexibility is good, in the face of obstacles or trench excavation in straight pipe laying conditions can not directly, but the ductile iron pipe can not, it is sometimes necessary to use the words such as elbow or tube fittings to connect the transition. In this way, the HDPE pipe is superior to the ductile iron pipe in the pipe fittings.

- Q: Are ductile iron pipes suitable for installation in areas with high soil settlement and consolidation?

- Ductile iron pipes are commonly used in areas where there is significant soil settlement and consolidation. One of the main advantages of these pipes is their ability to withstand external loads and accommodate ground movement. Compared to other pipe materials, ductile iron pipes are known for their strength and flexibility, making them more resistant to soil settlement and consolidation. They have a higher tensile strength and can withstand heavy loads and ground vibrations without cracking or breaking. This makes them suitable for areas with soil prone to settlement and consolidation. Moreover, ductile iron pipes have a high resistance to corrosion and can withstand aggressive soil conditions, which are often found in areas prone to settlement and consolidation. They are also less likely to be damaged by external factors such as roots or rocks, making them even more suitable for installation in such areas. However, it is important to consider the specific conditions of the site and consult with engineers or experts who are familiar with the local soil conditions. Factors such as the magnitude and rate of settlement, soil type, groundwater levels, and construction methods should be taken into account when determining whether ductile iron pipes are appropriate for installation in areas with high soil settlement and consolidation. In conclusion, ductile iron pipes are generally a suitable choice for installation in areas with high soil settlement and consolidation. Their strength, flexibility, resistance to corrosion, and ability to withstand external loads make them a reliable option for these conditions. Nevertheless, it is always recommended to assess the specific site conditions and consult with professionals to ensure the most appropriate pipe material is selected for each project.

- Q: What are the different types of valves available for ductile iron pipe?

- There are several types of valves available for ductile iron pipe, including gate valves, butterfly valves, check valves, ball valves, and globe valves.

- Q: Can ductile iron pipes be used for firefighting systems?

- Ductile iron pipes are capable of being utilized in firefighting systems. This material, known for its strength and resilience, can withstand intense pressures and extreme temperatures, thereby making it a suitable option for transporting water in such systems. Moreover, the pipes' resistance to corrosion and ability to handle external loads guarantee their long-term dependability and effectiveness. Furthermore, ductile iron pipes possess exceptional fire-resistant qualities, as they are non-combustible, do not emit harmful fumes, and do not contribute to the propagation of fire. Consequently, due to their robustness, durability, and fire resistance, ductile iron pipes are widely chosen and trusted for firefighting systems.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1989 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | Mid East Europe; Eastern Asia; South Africa; |

| Company Certifications | ISO 9001:2008;ISO2531:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 2000 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ductile Iron Pipe Mechnical Joint K Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meter m

- Supply Capability:

- 250000 Ton Per Year m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords