ISO2531 Socket Spigot Ductile Iron Pipe K8

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meter m

- Supply Capability:

- 250000 Ton Per Year m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

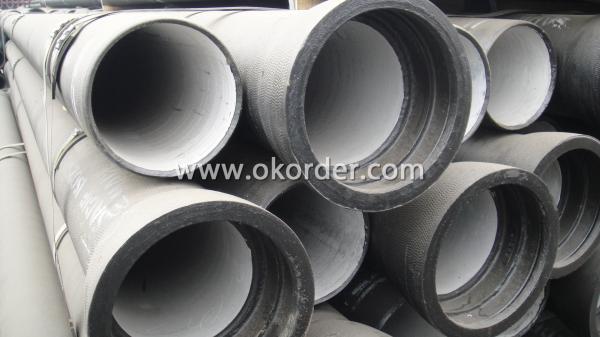

General Introduction and Specifications of ISO2531 Socket Spigot Ductile Iron Pipe K8

Standard: Pipes according to ISO2531/EN545

Joint: T Type joint

Size: DN80-DN2000

Effective length: 6m/pc or 5.7m/pc or 5.5m/pc

Internal lining: cement mortar lining comply with ISO4179

External coating: sprayed metallic Zinc coating (min.130g/m2) according to ISO8179 + bitumen painting (min.70μm) according to BS3416.

Gasket: Matched 100% natural rubber gasket in accordance with ISO4633.

Applications of ISO2531 Socket Spigot Ductile Iron Pipe K8

Design Flexibility: Pipes will safely function over a wide range of operating pressure, trench loads and installation conditions. Standard design includes generous factor of safety to protect against unknowns.

Easier Handing: Ductile Iron Pipes can be more easily maneuvered under and around existing underground obstructions, thereby eliminating unnecessary changes in line or grade.

Superior Joints: Easily assembled push in joints speed job progress, minimize installation cost. Joint remains leakproof under all operating pressures.

A complete Range: Ductile Iron Pipes are available with complete range of fittings and accessories in size from 80 to 2000mm dia. And a variety of lining and coatings for varied service conditions.

Standard Wall Thickness of ISO2531 Socket Spigot Ductile Iron Pipe K8

Nominal Wall Thickness of pipe:

e=K(0.5+0.001*DN)

Where, DN: Nominal diameter; K: Coefficient(K=7,8,9,10,11,12...)

Nominal Wall Thickness of pipe fittings:

e=7+0.014*DN (K=14)

e=6+0.012*DN (K=12)

Packing, Delivery and transport of ISO2531 Socket Spigot Ductile Iron Pipe K8

Show for ISO2531 Socket Spigot Ductile Iron Pipes K8

- Q: How do ductile iron pipes perform in high-temperature water applications?

- Ductile iron pipes are known for their strength, durability, and excellent mechanical properties, which make them suitable for a wide range of applications. However, when it comes to high-temperature water applications, certain considerations need to be taken into account. Ductile iron pipes generally perform well in high-temperature water applications up to a certain threshold. The exact temperature limit depends on the specific grade of ductile iron used and the duration of exposure to high temperatures. In general, ductile iron pipes can withstand temperatures up to 350-400 degrees Fahrenheit for short periods without significant degradation or loss of strength. However, it is important to note that prolonged exposure to high temperatures can have detrimental effects on ductile iron pipes. At elevated temperatures, ductile iron pipes may experience a phenomenon called thermal degradation, which can lead to reduced mechanical properties, increased brittleness, and even cracking or failure over time. To mitigate the risks associated with high-temperature water applications, several measures can be taken. Firstly, selecting the appropriate grade of ductile iron with a higher temperature tolerance can enhance the pipe's performance. Secondly, implementing proper insulation or heat shielding measures can help minimize the direct heat transfer to the pipes, thereby reducing the potential for thermal degradation. Additionally, regular monitoring and maintenance of ductile iron pipes in high-temperature water applications are crucial to identify any signs of degradation or damage early on and take appropriate remedial actions to prevent failure. In summary, while ductile iron pipes can generally perform well in high-temperature water applications, it is important to carefully consider the specific conditions and requirements of the application to ensure their long-term performance and integrity.

- Q: How do ductile iron pipes handle traffic vibrations?

- Ductile iron pipes are known for their exceptional strength and durability, making them highly capable of handling traffic vibrations. The inherent properties of ductile iron make it more resistant to fractures or cracks caused by external forces, including vibrations induced by traffic. The material's high tensile strength and elasticity allow ductile iron pipes to absorb and dissipate the energy generated by traffic vibrations. This helps to minimize the impact on the pipes and prevent any significant damage or failure. Additionally, the ductility of the material allows it to deform slightly under stress without breaking, further enhancing its ability to withstand vibrations. Furthermore, ductile iron pipes have superior resistance to corrosion and other forms of deterioration. This resistance ensures that the pipes maintain their structural integrity over an extended period, even when subjected to repetitive vibrations caused by heavy traffic. Overall, ductile iron pipes are well-equipped to handle traffic vibrations due to their robust nature, ability to absorb energy, and resistance to corrosion. These features make them a reliable choice for underground infrastructure in areas with high traffic volumes, ensuring a long-lasting and efficient pipeline system.

- Q: Can ductile iron pipes be used for geothermal systems?

- Yes, ductile iron pipes can be used for geothermal systems. Ductile iron is known for its strength, durability, and corrosion resistance, making it suitable for various applications including geothermal systems. These pipes can handle high temperatures and pressure fluctuations commonly found in geothermal systems. Additionally, ductile iron pipes have excellent thermal conductivity properties, allowing for efficient heat transfer between the geothermal fluid and the surrounding environment. Therefore, ductile iron pipes are a viable option for transporting geothermal fluids in geothermal systems.

- Q: What is the expected fire resistance of ductile iron pipes?

- The expected fire resistance of ductile iron pipes is high due to their ability to withstand high temperatures without losing structural integrity. They have a melting point of approximately 1200°C, making them suitable for applications where fire protection is crucial.

- Q: Can ductile iron pipe be used for underground fire protection systems?

- Yes, ductile iron pipe can be used for underground fire protection systems. Ductile iron pipe is a durable and reliable material that is commonly used in various applications, including water and wastewater systems, as well as fire protection systems. It has excellent strength, corrosion resistance, and longevity, making it suitable for underground installations. When it comes to fire protection systems, ductile iron pipe can effectively handle high-pressure water flow and withstand extreme conditions, making it an ideal choice for underground installations. It is capable of withstanding the intense heat and pressure that may occur during a fire event. Additionally, ductile iron pipe is available in various sizes and configurations, allowing for flexibility in design and installation. It is also compatible with different types of fittings and accessories, making it easy to connect to other components of the fire protection system. Overall, ductile iron pipe is a reliable and durable choice for underground fire protection systems, providing the necessary strength and longevity to ensure the safety of the premises and its occupants.

- Q: How does ductile iron pipe perform in areas with high soil contamination?

- Ductile iron pipe performs exceptionally well in areas with high soil contamination due to its inherent strength, durability, and corrosion resistance properties. The material used in manufacturing ductile iron pipes is highly resistant to chemical attack, making it suitable for handling various types of contaminated soils, including those with high levels of acids, alkalis, and other corrosive substances. The corrosion resistance of ductile iron pipes is primarily attributed to their protective internal and external linings, which are designed to prevent contact between the pipe material and the surrounding soil or fluids. These linings act as a barrier, preventing the penetration of corrosive elements and reducing the risk of pipe degradation or failure. Additionally, ductile iron pipes can be further protected by applying external coatings or cathodic protection systems, which enhance their resistance to soil contamination and extend their service life. In areas with high soil contamination, ductile iron pipes offer significant advantages over other materials such as steel or concrete. Their high strength allows them to withstand the external loads imposed by the contaminated soil, reducing the risk of structural failure or deformation. Moreover, the inherent flexibility of ductile iron allows it to absorb ground movements or settlement without compromising its integrity, making it a reliable choice for areas prone to soil instability or shifting. Furthermore, ductile iron pipes have a smooth internal surface, which minimizes friction and helps maintain efficient flow rates even in the presence of contaminants. This characteristic is particularly important in areas with high soil contamination, where debris or sedimentation can accumulate and hinder fluid flow. The smooth bore of ductile iron pipes reduces the risk of clogging and ensures the continuous and reliable conveyance of fluids, even in challenging soil conditions. Overall, ductile iron pipe is a highly suitable choice for areas with high soil contamination. Its excellent corrosion resistance, strength, flexibility, and smooth internal surface make it a reliable and durable solution for conveying fluids in these challenging environments.

- Q: Are ductile iron pipes suitable for use in desalination plants?

- Yes, ductile iron pipes are suitable for use in desalination plants. Ductile iron is known for its high strength and durability, making it capable of withstanding the harsh conditions and corrosive nature of desalination processes. Additionally, ductile iron pipes have excellent resistance to internal and external corrosion, making them a reliable choice for transporting the high-pressure brine and freshwater in desalination plants.

- Q: Are ductile iron pipes suitable for wastewater treatment plants?

- Ductile iron pipes are highly suitable for wastewater treatment plants. They possess exceptional strength and durability, making them resistant to corrosion. Consequently, these pipes are an excellent choice for managing wastewater, which often contains corrosive elements. Moreover, ductile iron pipes boast remarkable tensile strength and can endure high pressure, critical for the transportation of wastewater in treatment plants. The flexibility of these pipes also permits easy installation and maintenance, ultimately reducing both cost and time required for wastewater treatment plants. In summary, ductile iron pipes are extensively utilized in wastewater treatment plants due to their durability, resistance to corrosion, and their ability to handle the challenging conditions present in such facilities.

- Q: How much is the installation cost of the ductile iron tube?

- From the hydraulic performance, because ductile pipe specifications generally refers to the inner diameter of PE pipe diameter specifications generally refers to the same specifications, because under the condition of ductile pipe can achieve greater runoff; from the installation and maintenance cost, ductile pipe have more favorable price. The inner wall of zinc spray, anti-corrosion materials such as cement mortar.

- Q: Can ductile iron pipes be used for fire protection systems?

- Yes, ductile iron pipes can be used for fire protection systems. Ductile iron is a type of cast iron that exhibits high strength and flexibility, making it suitable for a wide range of applications, including fire protection systems. It has excellent mechanical properties, including high tensile strength and impact resistance, which are important factors for withstanding the high pressures and stresses that can occur during fire suppression efforts. Ductile iron pipes are known for their durability and longevity, which is crucial for fire protection systems that need to be reliable and functional for extended periods of time. They have a longer lifespan compared to other materials, such as PVC or galvanized steel, and are less prone to corrosion, which is especially important for fire protection systems as they need to remain operational even after long periods of inactivity. Furthermore, ductile iron pipes have excellent fire resistance properties. They can withstand high temperatures without losing their structural integrity, ensuring that the fire protection system remains intact and functional during a fire emergency. This is crucial for ensuring the safety of occupants and minimizing property damage. In addition to their mechanical and fire-resistant properties, ductile iron pipes are also compatible with various types of fittings, valves, and accessories commonly used in fire protection systems. This allows for easy installation and integration into existing fire suppression networks. Overall, ductile iron pipes are a reliable and suitable choice for fire protection systems due to their high strength, durability, fire resistance, and compatibility with other system components.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1989 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | Mid East Europe; Eastern Asia; South Africa; |

| Company Certifications | ISO 9001:2008;ISO2531:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 2000 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

ISO2531 Socket Spigot Ductile Iron Pipe K8

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meter m

- Supply Capability:

- 250000 Ton Per Year m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords