Ductile Iron Pipe ISO2531 / EN545 / EN598 K9 DN100

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Ductile Iron Pipe Description :

DI pipe fittings are manufactured according to ISO 2531 or BS EN545 or BS4772 FOR POTABLE WATER ,internal is cement lining or wet epoxy coating;External is zinc plus bitumen or wet epoxy coating.

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets accoding to ISO4633

2.Main Features of the Ductile Iron Pipe:

1. Material: Ductile iron grade 500-7/ 450-10 in accordance with ISO1083

2. Standard: ISO 2531, EN545, EN598, ANSI, AWWA

3. Certificate: ISO9001, ISO14001, SGS, NSF, WRAS

4. Test: In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test

5. Length: 6m or cut into 5.6m, 5.7m, 5.8m

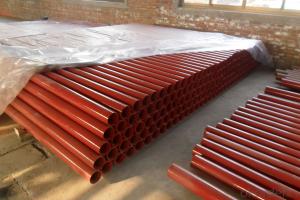

3.Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

Internal lining:ductile iron pipes shall have an internal cement mortar lining in acc with ISO4179.

External coating:ductile iron pipes shall be externally coated with metallic zinc spray plus a further layer of resin painting to ISO8179.

Gasket: 100% SBR/NBR/EPDM rubber gasket in accordance with ISO4633.

Packing:ductile iron pipes from DN100 to DN300 be bundled with steel belts, others are in bulk.

5.FAQ:

1.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

2.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

- Q: How do ductile iron pipes handle water hammer in high-rise buildings?

- Ductile iron pipes are well-suited to handle water hammer in high-rise buildings due to their inherent strength and durability. These pipes have the ability to withstand sudden changes in water flow and pressure, effectively reducing the impact of water hammer. Additionally, ductile iron pipes have excellent sound attenuation properties, which further minimizes the noise and vibrations caused by water hammer. Overall, ductile iron pipes offer reliable and long-lasting performance, making them an ideal choice for managing water hammer in high-rise buildings.

- Q: How is ductile iron pipe installed?

- The installation of ductile iron pipe can be carried out using two different methods: trenchless technology or the open-cut method. When utilizing trenchless technology, a hole is drilled into the ground, and hydraulic jacks or winches are used to push or pull the ductile iron pipe into the hole. This approach minimizes disruptions to the surrounding environment and reduces the need for extensive excavation. On the other hand, the open-cut method involves excavating a trench to the necessary depth and width for the ductile iron pipe. The trench is then prepared by removing any debris or obstructions and ensuring a stable base. The pipe is subsequently lowered into the trench and aligned correctly with the assistance of laser or surveying equipment. Once the pipe is in place, joints are connected using either a rubber gasket or mechanical joint. The joints are carefully sealed to prevent any leakage. Backfill material is then meticulously placed around the pipe, ensuring proper compaction for stability and support. To avoid excessive settlement, the backfill is applied in layers. After completing the installation, the pipe undergoes testing to ensure its integrity. This may involve hydrostatic testing, where water is filled into the pipe and monitored for any signs of leakage or pressure loss. Overall, the installation of ductile iron pipe necessitates careful planning, excavation, alignment, joint connection, backfilling, and testing. It is crucial to adhere to industry standards and guidelines to achieve a successful and reliable installation that meets the required specifications.

- Q: What is the expected joint flexibility of ductile iron pipes?

- Due to the inherent material properties of ductile iron pipes, their expected joint flexibility is typically high. Ductile iron is renowned for its exceptional ductility, which enables it to deform without fracturing. This quality empowers ductile iron pipes to withstand external loads, ground movement, and pressure fluctuations without significant damage. To accommodate movement, the joints in ductile iron pipes are usually designed to provide additional flexibility. The most commonly used joint type in ductile iron pipes is the push-on joint. This joint type permits angular deflection and axial movement. It consists of a rubber gasket that creates a watertight seal and allows for slight movement between pipe sections. The expected joint flexibility varies depending on several factors, such as pipe diameter, joint type, and installation methods. Generally, ductile iron pipes can accommodate angular deflection within a certain range, typically ranging from 5 to 10 degrees, depending on the joint design. Axial movement can also be accommodated to some extent, allowing for the expansion and contraction of the pipe system. It is important to note that the specific manufacturer and product specifications may affect joint flexibility. Therefore, it is recommended to consult the manufacturer's guidelines and specifications to determine the expected joint flexibility of a particular ductile iron pipe product.

- Q: How are ductile iron pipes connected or jointed together?

- Ductile iron pipes are typically connected or jointed together using various methods such as flanged joints, push-on joints, mechanical joints, or restrained joints. These methods ensure a secure and leak-free connection between the pipes, providing a reliable and durable pipeline system.

- Q: Are ductile iron pipes resistant to biological growth?

- Indeed, ductile iron pipes exhibit a general resistance to biological growth. Ductile iron, a robust and enduring substance, finds widespread application in water and sewage systems. Its sleek exterior hampers the proliferation of bacteria, fungi, and other microorganisms that foster biological growth. Moreover, ductile iron pipes frequently receive protective linings or coatings, for instance, cement mortar or epoxy, which heighten their resistance to biological growth. Nevertheless, it is crucial to acknowledge that no material remains entirely impervious to biological growth, necessitating regular maintenance and cleansing of the pipes to ensure sustained resilience in the long run.

- Q: What is a slide in type T flexible interface?

- As long as the socket is inserted into the slot, the installation is quick, labor-saving and airtight, and what is good is also good

- Q: What is the cost of ductile iron pipe compared to other pipe materials?

- The cost of ductile iron pipe compared to other pipe materials can vary depending on various factors such as the size, length, and specific requirements of the project. However, generally speaking, ductile iron pipe tends to be more expensive than some of the alternative pipe materials such as PVC or HDPE (high-density polyethylene) pipes. Ductile iron pipe is known for its exceptional strength and durability, making it suitable for a wide range of applications including water distribution, wastewater systems, and industrial piping. Its robustness and longevity contribute to its higher cost compared to other pipe materials. On the other hand, PVC and HDPE pipes are often more affordable options due to their lower production and material costs. Additionally, these materials are lightweight, easy to install, and resistant to corrosion, which can lead to cost savings during installation and maintenance. It is important to note that while ductile iron pipe may have a higher upfront cost, its superior strength and longevity can result in long-term cost savings by minimizing the need for frequent repairs or replacements. The choice of pipe material should be made considering the specific project requirements, budget constraints, and the anticipated lifespan of the infrastructure.

- Q: Can the sealing ring of ductile iron pipe be reused?

- It is better not to have used things, easy aging, sealed, the best to use new

- Q: What are the interface forms of ductile iron pipes? The best drawings are available. Thank you

- Because of this interface and the corresponding T sealing aprons can withstand greater deflection angle and greater tolerances, especially suitable for unstable formations and corners.

- Q: What is the typical weight of ductile iron pipes?

- The weight of ductile iron pipes can differ according to their size and thickness. Nonetheless, as a broad reference, smaller diameter pipes typically weigh around 1 pound per foot, while larger diameter pipes can weigh several hundred pounds per foot. The weight of ductile iron pipes is influenced by factors like the dimensions of the pipes, the thickness of their walls, and the particular requirements of the intended use. It is essential to acknowledge that these weights are approximate and subject to variation depending on the manufacturer and product specifications.

Send your message to us

Ductile Iron Pipe ISO2531 / EN545 / EN598 K9 DN100

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords