Self-restrained Joint Ductile Iron Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Metric Ton m.t.

- Supply Capability:

- 300000 Metric Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Overview of Ductile Iron Pipe

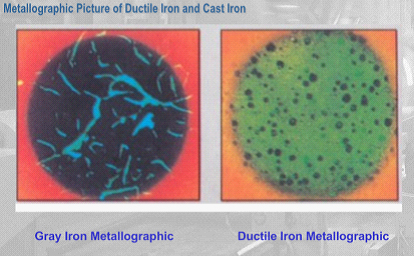

Ductile cast iron, also called ductile iron, spheroidal graphite iron, or nodular cast iron, is a type of cast iron invented in 1943. While most varieties of cast iron are brittle, ductile cast iron is much more flexible and elastic, due to its nodular graphite inclusions.

Graphite particles exist in the form of sphericity in ductile cast iron. Sizes graphite particle are restricted to 6 -7 class and spheroidizing rate should not be less than 80%. Thus after the spheroidizing process, ductile iron will be endowed with mechanical properties of both cast iron and steel.

Much of the production of ductile iron is in the form of ductile cast iron pipe, used for water supply and sewerage design. Ductile cast iron pipe is stronger and easier to tap, requires less support and provides greater flow area compared with pipes made from other materials like PVC, concrete, polyethylene or steel. Ductile Iron Pipe is the most widely-used pipeline product in water supply and water drain/sewage projects.

General introduction of Self-restrained Joint Ductile Iron Pipe

•Material : Ductile Cast Iron

•Size Range : DN 80mm to DN 1200mm

•Unit Effective Length : 6m or 5.7m or negotiable

•Manufacture Standard: ISO 2531:1998/ EN 545:2006/EN 598:2007

•Annual capacity : 300,000 tons

•Coating Exterior: Zinc 130g/m2 according to ISO 8179-1 and bitumen coating 70 microns.

•Cement Interior: Portland Cement/ High Alumina Cement/ Sulphate Resisting Cement Lining according to ISO 4179

•Special requirements on external coating and internal lining can be applied

•We also provide accessories such as SBR/EPDM rubber gaskets, lubricant paste, pipe caps, PE sleeves, etc.

Mechanical Properties

|

Item |

Tensile Strength (N/mm2) |

Elongation(%) |

Proof Stress (N/mm2) |

Hardness HB | ||

|

DN80 TO DN2600 |

DN80 TO DN1000 |

DN1100 TO DN2000 |

DN80 TO DN1000 |

DN100 TO DN2000 | ||

|

Pipe |

≥420 |

≥10 |

≥7 |

≥270 |

≥300 |

≤230 |

|

Fittings |

≥420 |

≥5 |

≥300 |

≤250 | ||

Standard Lining and Coating

External Protection

Metallic zinc complying with the standard ISO8179,and bitumen,or special protective coating according to the customer’s requirement.

Notes:

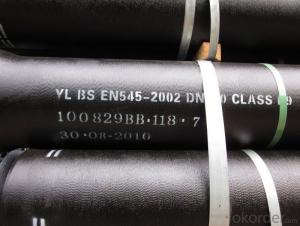

. Pipes and fittings conform to the requirements of International Standard ISO 2531,British Eurpean Standard BS

. EN545,and their extensions. If information given in English and Chinese differs,the English version prevails.

. Dimensions and masses of pipes and fittings are approximate and are for refererces only;accurate dimensions and

. masses should be confirmed with us at the time of placing order. Flanged joint pipes and fittings are generally

. available with PN10,PN16 and PN25. Socketed joint pipes and fittings generally available with T type and K type joints.

Features of Self-restrained Joint Ductile Iron Pipe:

. Ductile Iron Pipe offers proven reliability and the quality.

. It is quick and easy installation.

. The ductile iron pipe has high pressure capability.

Application:

Used for water and sewer lines.

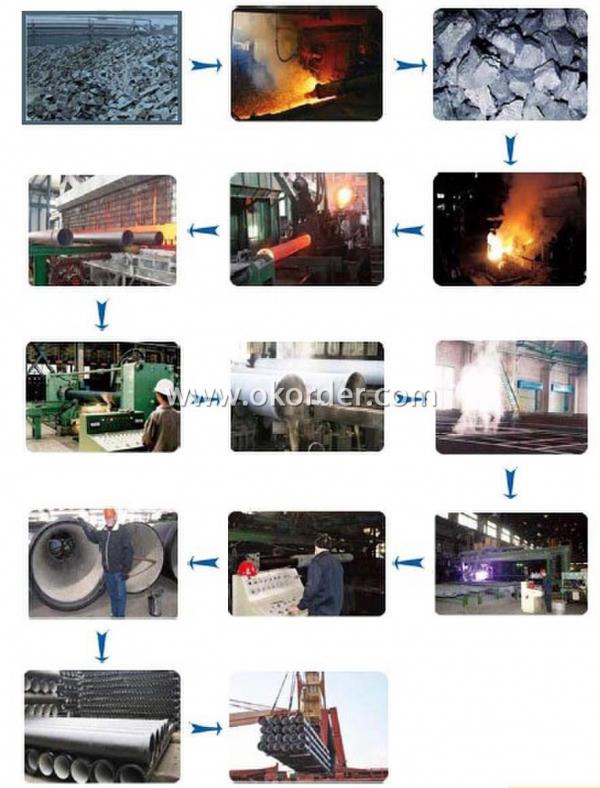

Production Process

Much of the production of ductile iron is in the form of ductile cast iron pipe, used for water supply and sewerage design. Ductile iron pipe is stronger and easier to tap, requires less support and provides greater flow area compared with pipes made from other materials like PVC, concrete, polyethylene or steel.

Specification of Self-restrained Joint Ductile Iron Pipe:

Standard wall thickness of Self-restrained Joint Ductile Iron Pipe

|

Nominal Diameter |

Wall Thickness(mm) | ||||||

|

DN(mm) |

Pipe |

Fittings | |||||

|

Class C |

K8 |

K9 |

K10 |

K12 |

K12 |

K14 | |

|

80 |

4.4 |

6 |

6.0 |

7 |

8.1 | ||

|

100 |

4.4 |

6.0 |

7.2 |

8.4 | |||

|

125 |

4.5 |

6.3 |

7.5 |

8.8 | |||

|

150 |

4.5 |

6.3 |

7.8 |

9.1 | |||

|

200 |

4.7 |

6.3 |

8.4 |

9.8 | |||

|

250 |

5.5 |

6.8 |

7.5 |

9 |

9 |

10.5 | |

|

300 |

6.2 |

6.4 |

7.2 |

8 |

9.6 |

9.6 |

11.2 |

|

350 |

6.3 |

6.8 |

7.7 |

8.5 |

10.2 |

10.2 |

11.9 |

|

400 |

6.5 |

7.2 |

8.1 |

9 |

10.8 |

10.8 |

12.6 |

|

450 |

6.9 |

7.6 |

8.6 |

9.5 |

11.4 |

11.4 |

13.3 |

|

500 |

7.5 |

8 |

9 |

10 |

12 |

12 |

14 |

|

600 |

8.7 |

8.8 |

9.9 |

11 |

13.2 |

13.2 |

15.4 |

|

700 |

8.6 |

9.6 |

10.8 |

12 |

14.4 |

14.4 |

16.8 |

|

800 |

9.6 |

10.4 |

11.7 |

13 |

15.6 |

15.6 |

18.2 |

|

900 |

11.6 |

11.2 |

12.6 |

14 |

16.8 |

16.8 |

19.6 |

|

1000 |

12.6 |

12 |

13.5 |

15 |

18 |

18 |

21 |

|

1200 |

13.6 |

13.6 |

15.3 |

17 |

20.4 |

20.4 |

22.8 |

|

1400 |

15.7 |

15.2 |

17.1 |

19 |

22.8 |

22.8 |

26.6 |

|

1500 |

16.7 |

16 |

18 |

20 |

24 |

24 |

31 |

|

1600 |

17.7 |

16.8 |

18.9 |

21 |

25.2 |

25.2 |

29.4 |

|

1800 |

19.7 |

18.4 |

20.7 |

23 |

27.6 |

27.6 |

32.2 |

|

2000 |

21.8 |

20 |

22.5 |

25 |

30 |

30 |

35 |

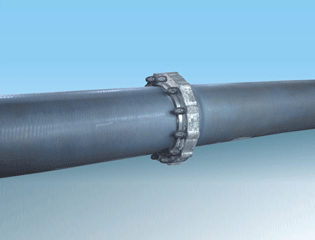

Self-restrained Joint

Self-restrained Type is a push-in self anchored joint. The principle of joint anchoring consists in transmitting the axial forces from one pipeline to the following one, thus ensuring that the joint does not come apart.

The application of self-restrained joints is of particular interest where congested conditions preclude concrete anchor block constructions or in poorly cohesive soils.Self-restrained joints combine the advantages of flexible joint pipes and welded joint pipes.

Photo of Self-restrained Joint Ductile Iron Pipe

- Q: How does ductile iron pipe perform in high-temperature environments?

- Ductile iron pipe performs well in high-temperature environments due to its superior strength and thermal resistance. It can withstand elevated temperatures without significant deformation or structural damage, making it a reliable choice for various applications requiring high-temperature resistance.

- Q: Are ductile iron pipes prone to external corrosion?

- Ductile iron pipes are generally not prone to external corrosion. This is due to the protective nature of the material itself. Ductile iron pipes are made of a strong and durable material that contains a significant amount of graphite. The graphite acts as a natural barrier against external corrosion, preventing the pipe from being affected by rust or other forms of oxidation. Additionally, ductile iron pipes are often coated with a protective layer, such as cement mortar or polyethylene, to further enhance their resistance to corrosion. These coatings provide an extra layer of protection, preventing any contact between the pipe and corrosive substances in the environment. However, it should be noted that while ductile iron pipes are generally resistant to external corrosion, they may still be susceptible to localized corrosion in certain conditions. Factors such as soil composition, moisture content, and the presence of certain chemicals can potentially lead to the corrosion of ductile iron pipes in specific areas. Therefore, proper maintenance and regular inspections are necessary to identify and address any potential corrosion issues promptly. Overall, ductile iron pipes are considered to be highly resistant to external corrosion, but like any other material, they require proper care and maintenance to ensure their long-term durability and reliability.

- Q: Can ductile iron pipes be made into clear tubes?

- Of course, you can also use as a pipe, but because of the appearance of cast iron pipe is not very beautiful, but relatively brittle, by external impact or bad insulation cold winter break, so according to your use of the environment to determine.

- Q: Are ductile iron pipes resistant to chemicals or solvents?

- Yes, ductile iron pipes are generally resistant to chemicals and solvents. Their strong and durable composition makes them suitable for carrying various substances, including acids, alkalis, and other corrosive materials, without significant degradation or damage. However, it is always recommended to consult specific chemical resistance charts or manufacturers' guidelines to ensure compatibility with specific chemicals or solvents.

- Q: Are ductile iron pipes suitable for sewer force mains?

- Yes, ductile iron pipes are suitable for sewer force mains. Ductile iron is a type of cast iron that has a higher level of strength and flexibility compared to traditional cast iron pipes. This makes it ideal for applications where the pipes need to withstand high pressure and heavy loads, such as sewer force mains. Ductile iron pipes have excellent resistance to corrosion and are highly durable, which is crucial for sewer systems that are exposed to various corrosive substances and harsh environments. They also have the ability to absorb vibrations and shocks, reducing the risk of pipe failures caused by external forces. Furthermore, ductile iron pipes are known for their long service life, often lasting for more than 100 years. This makes them a cost-effective choice for sewer force mains, as they require minimal maintenance and replacement over their lifetime. Overall, ductile iron pipes offer a reliable and durable solution for sewer force mains, providing the necessary strength, flexibility, and resistance to corrosion to ensure efficient and long-lasting sewer systems.

- Q: Can the sealing ring of ductile iron pipe be reused?

- It is better not to have used things, easy aging, sealed, the best to use new

- Q: What is ductile iron?

- Ductile iron is a type of cast iron that has been treated with magnesium or cerium to improve its mechanical properties. It is called "ductile" because it has a higher degree of ductility compared to other types of cast iron. Ductility refers to the ability of a material to be stretched or deformed without breaking. This characteristic makes ductile iron highly suitable for applications that require high strength and resistance to wear and tear, such as pipes, automotive components, and machinery parts. The addition of magnesium or cerium to the iron during the manufacturing process helps to form graphite in the structure, which gives ductile iron its unique properties. This graphite formation also helps to make the iron more flexible and less brittle, enabling it to absorb shock and vibration without fracturing. Overall, ductile iron offers a balance between the strength of cast iron and the flexibility of steel, making it a versatile material for various industrial applications.

- Q: What are the different sizes available for ductile iron pipe?

- Ductile iron pipes are available in a wide range of sizes to cater to various applications in the water and wastewater industry. The sizes of ductile iron pipes typically range from 3 inches to 64 inches in diameter. The most commonly used sizes include 4 inches, 6 inches, 8 inches, 10 inches, 12 inches, 16 inches, 20 inches, 24 inches, 30 inches, and 36 inches. However, ductile iron pipes can also be manufactured in larger sizes depending on specific project requirements. These different sizes allow for flexibility in designing and constructing water distribution systems, sewage networks, and other infrastructure projects. The selection of the appropriate size depends on factors such as the volume of flow, pressure requirements, and the distance the pipe needs to cover. It is worth mentioning that the size of a ductile iron pipe refers to its internal diameter, also known as the nominal bore. The actual outside diameter of the pipe may vary slightly depending on the manufacturer and the specific dimensions provided. When choosing a size for ductile iron pipes, it is essential to consider factors such as hydraulic capacity, installation requirements, and the compatibility with other pipeline components. Consulting with engineers and industry experts is advisable to ensure the correct size selection for each specific application.

- Q: Are ductile iron pipes suitable for underground installations?

- Yes, ductile iron pipes are suitable for underground installations. Ductile iron is a highly durable and strong material that can withstand the various pressures and stresses associated with underground environments. It has excellent resistance to corrosion, making it an ideal choice for underground applications where it may be exposed to moisture, soil, and other corrosive elements. Ductile iron pipes also have a high tensile strength, which allows them to withstand external loads and prevent cracking or breakage under ground movement or heavy traffic. Additionally, ductile iron pipes have a longer lifespan compared to other materials, making them a cost-effective option for underground installations. Overall, ductile iron pipes are a reliable and suitable choice for underground applications due to their durability, corrosion resistance, and long-term performance.

- Q: Can ductile iron pipes be used for water treatment facilities?

- Water treatment facilities can utilize ductile iron pipes. Ductile iron, a type of cast iron, boasts improved strength, flexibility, and durability. These characteristics render it suitable for a range of applications, including water treatment facilities. Ductile iron pipes exhibit exceptional resistance to corrosion, a crucial attribute for water treatment facilities where pipes come into contact with various chemicals and water contaminants. They can endure the demanding conditions and chemicals inherent in water treatment processes, ensuring a lengthy lifespan. Additionally, ductile iron pipes possess high tensile strength and can withstand elevated pressures. This makes them ideal for conveying water throughout the facility, encompassing the distribution system, pumping stations, and treatment units. They can handle the required flow rates and pressures without compromising pipe integrity. Furthermore, ductile iron pipes are renowned for their flexibility and resilience. They can tolerate ground movement and other external stresses, diminishing the likelihood of pipe failures and leaks. This proves invaluable in water treatment facilities where pipes frequently traverse diverse terrains and undergo regular maintenance activities. Moreover, ductile iron pipes offer cost-effective advantages over alternative pipe materials such as steel or PVC. They boast an extended lifespan, necessitate minimal maintenance, and exhibit low failure rates, thereby reducing overall operational and maintenance expenses for water treatment facilities. In conclusion, ductile iron pipes provide a dependable and durable solution for water treatment facilities. Their corrosion resistance, high tensile strength, flexibility, and cost-effectiveness render them a suitable choice for transporting water and chemicals within the facility, ensuring efficient and effective water treatment processes.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1958 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East, Africa, South Asia, Eastern Asia |

| Company Certifications | ISO 9001:2008;ISO2531:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 3000 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Self-restrained Joint Ductile Iron Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Metric Ton m.t.

- Supply Capability:

- 300000 Metric Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords