Ductile Iron Pipe ISO2531 / EN545 / EN598 K9

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200

- Supply Capability:

- 10000 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets

accoding to ISO4633

3) we can do third party inspection according to customer's request.

4) Our products have been sold to many international market,

such as Middle East and South East Asia and Africa.

2,Main Features of the Ductile Iron Pipe:

·High yield strength

·High tensile Strength

·High corrosion resistance

·Pressure Resistence

·Anti-corrosion

·Installation is convenient

·Satisfy the highest hygienic standards

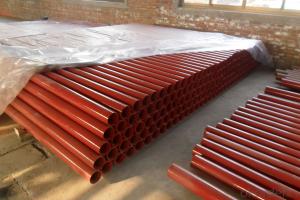

3,Ductile Iron Pipe Images:

4.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: What is the internal lining used in ductile iron pipes?

- The internal lining used in ductile iron pipes is typically a cement mortar lining. This lining is applied to the inside surface of the pipe to protect it from corrosion and abrasion. The cement mortar lining helps to extend the lifespan of the pipes and ensures they can withstand the harsh conditions of transporting water or sewage. Additionally, the lining also improves the hydraulic efficiency of the pipes by reducing friction and preventing the formation of biofilms or deposits on the inner surface. Overall, the use of cement mortar lining in ductile iron pipes is essential for maintaining the integrity and functionality of the infrastructure.

- Q: What is the typical pressure rating of ductile iron pipes?

- The pressure rating of ductile iron pipes varies depending on the application and size, typically designed to endure high pressure levels. In water and wastewater systems, for instance, ductile iron pipes generally have a pressure rating of 250 psi or higher. In industrial applications like oil and gas pipelines, larger pipes can have a pressure rating ranging from 350 psi to 500 psi or more. To determine the precise pressure rating for a specific ductile iron pipe, it is crucial to consult the manufacturer's specifications and industry standards.

- Q: Are ductile iron pipes suitable for underground storage tanks?

- No, ductile iron pipes are not suitable for underground storage tanks.

- Q: How does ductile iron pipe perform in areas with high soil acidity?

- Due to its innate corrosion resistance, ductile iron pipe is highly effective in areas with high soil acidity. It is specifically engineered to endure harsh environments and incorporates a safeguarding lining that shields against damage caused by acidic soil. This lining functions as a barrier, safeguarding the pipe from corrosion induced by the acid in the soil. Moreover, ductile iron pipe exhibits exceptional resistance to external loads, making it well-suited for regions with unstable soil conditions. In conclusion, ductile iron pipe is a dependable option for areas with high soil acidity, as it can withstand corrosive effects and offer enduring performance.

- Q: Can ductile iron pipes be used for underground parking lot drainage?

- Ductile iron pipes are indeed suitable for drainage in underground parking lots. This robust material is frequently utilized in underground piping systems due to its strength and durability. It exhibits exceptional resistance to corrosion, making it an ideal choice for situations where the pipes will come into contact with moisture and water. Furthermore, ductile iron pipes possess considerable tensile strength, enabling them to bear heavy loads and endure the pressure exerted by vehicles in a parking lot. Consequently, opting for ductile iron pipes for underground parking lot drainage ensures a dependable and enduring solution.

- Q: Do ductile iron pipes require internal linings for potable water?

- No, ductile iron pipes do not require internal linings for potable water. Ductile iron is a type of iron that has been treated to enhance its strength and flexibility. It is commonly used for water distribution systems due to its durability and resistance to corrosion. Unlike other materials, such as cast iron or steel, ductile iron pipes have a protective layer called a cement-mortar lining, which provides an effective barrier against corrosion and prevents the leaching of any harmful substances into the water. This lining is applied during the manufacturing process and is designed to withstand the corrosive properties of potable water, making internal linings unnecessary. Additionally, the smooth surface of ductile iron pipes helps to maintain the quality and flow of water without the need for additional linings.

- Q: How to control mortar proportioning in ductile iron pipe cement coating

- The calculation steps are: first to calculate the amount of plastering engineering (area), and then check the "national construction basic quota" quota in the corresponding amount of mortar project, engineering quantity multiplied by the amount of mortar that fixed amount of mortar, the mortar amount multiplied by the corresponding mix ratio of mortar, the consumption of raw materials can be obtained.

- Q: How does ductile iron pipe perform in areas with high ground movement?

- Ductile iron pipe performs well in areas with high ground movement due to its inherent flexibility and strength. Its ability to bend and absorb ground movements makes it less susceptible to cracking or breaking compared to other rigid pipe materials. Additionally, the material's high tensile strength and durability ensure that it can withstand the stresses caused by ground movement without compromising its structural integrity.

- Q: Disadvantages of ductile iron pipes

- Compared with cast iron, ductile iron has an absolute advantage in strength. The tensile strength of ductile iron is 60K, while the tensile strength of cast iron is only 31k. The yield strength of ductile iron is 40K, while the cast iron does not show yield strength, and eventually breaks. The strength to cost ratio of ductile iron is far superior to that of cast iron.

- Q: How much is the manual installation fee of ductile iron pipes from 100 to 150 per metre?

- Upstairs said 9 yuan per meter, about the same, if you use the special (ductile iron pipe installation tool) construction greatly saves the labor cost, very fast and convenient, can search, is a special tool for the new, I hope to help you.

Send your message to us

Ductile Iron Pipe ISO2531 / EN545 / EN598 K9

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200

- Supply Capability:

- 10000 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords