Ductile Iron Pipe ISO2531 / EN545 / EN598 K9 DN200

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Ductile Iron Pipe Description :

DI pipe fittings are manufactured according to ISO 2531 or BS EN545 or BS4772 FOR POTABLE WATER ,internal is cement lining or wet epoxy coating;External is zinc plus bitumen or wet epoxy coating. We also manufacture ductile iron fittings with fusion bonded epoxy both inside and outside. All the producets are sutible to water pipes fields.We have passed ISO9001,ISO14001,OHSMS18001 certificate.

2.Main Features of the Ductile Iron Pipe:

1).Quality guarantee

• Chemical checking

• NDE after rough machining

• Mechanical testing after heat treatment

• Final NDE,dimension inspected

2).Quality document

• Full Q.A document as per client request

3).Packing and Shipping

• standard export package(carton/wooden case/pallet)

• accept FOB,FAS,CNF,CIF door to door etc or customer designated shipping agent

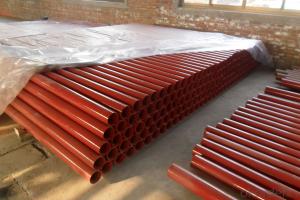

3.Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

Surface Finishes: Bare, Oiled, Mill Varnish, Galv,FBE, FBE Dual, 3LPE, 3LPP, Coal Tar,Concrete Coating and Tape Wrap

End Finishes: Beveled, Square Cut, Threaded, hat

Additional Services: Internal Coating

Packaging: packed in bag, plastic bag, steel strip, steel wire,double wire, iron box, wooden box, tarpaulin, plastic sheeting

Inspection: MOODY SGS BV GL DNV ABS LIOYD’S

Test: X-ray, UT, magnetic particle,inspection,hydrostatic test.

5.FAQ:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: What are the different pressure classes available for ductile iron pipe?

- The different pressure classes available for ductile iron pipe include Class 100, Class 150, Class 200, Class 250, Class 300, Class 350, and Class 400.

- Q: Are ductile iron pipes suitable for use in paper mills?

- Yes, ductile iron pipes are suitable for use in paper mills. Ductile iron is known for its high strength and durability, making it an excellent choice for various industrial applications, including paper mills. These pipes can withstand high-pressure systems and are resistant to corrosion, making them suitable for transporting water, chemicals, and other fluids commonly used in paper mills. Additionally, ductile iron pipes have good impact resistance, which is beneficial in an environment where heavy machinery and equipment are often present. Overall, ductile iron pipes are a reliable and long-lasting option for paper mills due to their strength, durability, corrosion resistance, and ability to handle high-pressure systems.

- Q: An urban infrastructure construction, water supply pipe is ductile iron pipe and PE pipe, thank you

- Water supply pipe is the first choice, with high cost performance. Compared with the PE pipe, from the installation time, ductile pipe PE pipe installation is simple and rapid, and after the installation of internal and external bearing pressure better;

- Q: How can the internal and external walls of ductile iron pipes be protected from corrosion?

- The inner wall is not needed and the outer wall is painted

- Q: Can ductile iron pipes be used for pressure reducing stations?

- Ductile iron pipes are indeed capable of being utilized in pressure reducing stations. Renowned for their robustness and resilience, these pipes are well-suited for managing applications involving high pressure. Their exceptional resistance to corrosion allows them to endure the mechanical pressures and strains typically associated with pressure reducing stations. Moreover, the smooth interior surface of ductile iron pipes minimizes friction losses and contributes to maintaining a consistent and regulated pressure within the system. Consequently, it can be concluded that ductile iron pipes are a dependable and frequently employed material in pressure reducing stations.

- Q: What are the different coating thickness options for ductile iron pipe?

- The coating thickness options for ductile iron pipe can vary depending on the specific application and requirements. Generally, there are three common coating thickness options for ductile iron pipe: 1. Standard Thickness: The standard coating thickness for ductile iron pipe is usually between 200 and 250 microns (8-10 mils). This thickness provides adequate protection against corrosion and abrasion in most soil and water environments. 2. Increased Thickness: In some cases, where the pipe is exposed to more aggressive environments or requires a longer service life, an increased coating thickness may be necessary. This can range from 300 to 500 microns (12-20 mils) or even more, depending on the specific requirements. 3. Specialized Coatings: For particularly demanding applications, specialized coatings may be used. These coatings can provide even higher levels of protection against corrosion, abrasion, or chemical exposure. The thickness of these specialized coatings can vary significantly depending on the specific coating material and application requirements. It is important to note that the selection of coating thickness should be based on a thorough assessment of the environmental conditions, intended service life, and any applicable industry standards or specifications. Consulting with a coating manufacturer or a corrosion specialist is recommended to determine the appropriate coating thickness for a specific ductile iron pipe application.

- Q: Can ductile iron pipes be used for water treatment facilities?

- Yes, ductile iron pipes can be used for water treatment facilities. Ductile iron is a type of cast iron that has enhanced strength, flexibility, and durability. These properties make it suitable for use in various applications, including water treatment facilities. Ductile iron pipes have excellent corrosion resistance, which is crucial in water treatment facilities where the pipes come in contact with different chemicals and water contaminants. They can withstand the harsh conditions and chemicals found in water treatment processes, ensuring a long service life. Moreover, ductile iron pipes have high tensile strength and are capable of withstanding high pressure. This makes them suitable for carrying the water throughout the facility, including the distribution system, pumping stations, and treatment units. They can handle the required flow rates and pressures without compromising the integrity of the pipes. In addition, ductile iron pipes are known for their flexibility and resilience. They can withstand ground movement and other external stresses, minimizing the risk of pipe failures and leaks. This is important in water treatment facilities where pipes often pass through different terrains and undergo frequent maintenance activities. Furthermore, ductile iron pipes are cost-effective compared to other alternative pipe materials like steel or PVC. They have a long life span, require minimal maintenance, and have low failure rates, reducing the overall operational and maintenance costs for water treatment facilities. Overall, ductile iron pipes offer a reliable and durable solution for water treatment facilities. Their corrosion resistance, high tensile strength, flexibility, and cost-effectiveness make them a suitable choice for transporting water and chemicals within the facility, ensuring efficient and effective water treatment processes.

- Q: What does ductile iron pipe "ND200" mean?

- Generally speaking, the diameter of the pipe can be divided into outer diameter, inner diameter and nominal diameter. The pipe is a seamless steel pipe pipe diameter by the letter D to represent, then additional outer diameter size and thickness, such as diameter of seamless steel pipe 108, a wall thickness of 5MM, denoted by D108*5, is also used outside said, such as De63 plastic pipe, such as reinforced concrete pipe, cast iron pipe, galvanized steel pipe, said the DN, in the design drawings is generally used to represent the nominal diameter, nominal diameter is a standard in order to design and manufacture and maintenance convenient set artificially, with nominal diameter, tube (or pipe) specification name.

- Q: How are ductile iron pipes different from cast iron pipes?

- Ductile iron pipes are different from cast iron pipes in terms of their composition and properties. Ductile iron pipes are made from a type of cast iron that has been treated with magnesium to improve its strength and flexibility. This makes ductile iron pipes more durable, impact-resistant, and less prone to cracking or breaking compared to traditional cast iron pipes. Additionally, ductile iron pipes have a higher tensile strength, allowing them to withstand higher internal and external pressures. In summary, ductile iron pipes are a more modern and advanced version of cast iron pipes, offering improved performance and longevity.

- Q: How do ductile iron pipes compare to PVC pipes?

- Ductile iron pipes and PVC pipes are two common materials used for plumbing and water distribution systems. While both have their advantages and disadvantages, there are several factors to consider when comparing the two. Strength and Durability: Ductile iron pipes are known for their exceptional strength and durability. They have a high resistance to pressure and can withstand heavy loads, making them suitable for underground applications and areas with high traffic. On the other hand, PVC pipes are less sturdy and can be more vulnerable to cracking or breaking under extreme conditions. However, PVC pipes are resistant to corrosion and do not rust, which can be a significant advantage in certain environments. Installation and Maintenance: Ductile iron pipes are heavier than PVC pipes, making them more challenging to handle and install. They require specialized equipment and skilled labor to be properly installed. In contrast, PVC pipes are lightweight and easy to handle, making them simpler and quicker to install. Additionally, PVC pipes require less maintenance as they do not corrode or develop mineral deposits over time, unlike ductile iron pipes which may require regular cleaning and maintenance to prevent rust and sediment buildup. Cost: PVC pipes are generally more affordable than ductile iron pipes. The lower material and installation costs associated with PVC pipes make them a popular choice for residential and commercial plumbing projects on a budget. Ductile iron pipes, while offering superior strength and durability, tend to be more expensive due to the higher cost of materials, specialized installation requirements, and additional maintenance expenses. Environmental Impact: PVC pipes are made from plastic materials, which are derived from non-renewable resources and can have a negative impact on the environment during production and disposal. Ductile iron pipes, on the other hand, are made from recycled iron and have a longer lifespan, reducing the need for replacement and minimizing waste. However, it is worth noting that PVC pipes can be recycled, and many manufacturers have implemented sustainable practices to minimize their environmental footprint. In summary, ductile iron pipes and PVC pipes have distinct characteristics that make them suitable for different applications. Ductile iron pipes excel in strength and durability, making them ideal for heavy-duty applications, while PVC pipes offer cost-effectiveness, easy installation, and resistance to corrosion. Ultimately, the choice between the two materials depends on the specific requirements, budget, and environmental considerations of the project.

Send your message to us

Ductile Iron Pipe ISO2531 / EN545 / EN598 K9 DN200

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords