Flange Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Metric Ton pc

- Supply Capability:

- 300000 Metric Tons per Year pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

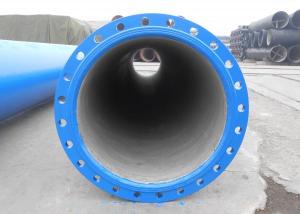

General introduction of Flange Pipe

•Material: Ductile Cast Iron

•Size Range: DN 80mm to DN 2000mm

•Unit Effective Length: 5.7m or 6m or negotiable

•Manufacture Standard: ISO 2531:1998/ EN 545:2006/EN 598:2007

•Annual capacity: 300,000 tons

• Internal lining: cement mortar lining comply with ISO4179.

External coating: sprayed metallic Zinc coating (min.130g/m2) according to ISO8179 + bitumen painting (min.70μm) according to BS3416.

Gasket: Matched 100% natural rubber gasket in accordance with ISO4633.

•Special requirements on external coating and internal lining can be applied

•We also provide accessories such as SBR/EPDM rubber gaskets, lubricant paste, pipe caps, PE sleeves, etc.

Features of Flange Pipes:

Ductile cast iron, also called ductile iron, spheroidal graphite iron, or nodular cast iron, is a type of cast iron invented in 1943. While most varieties of cast iron are brittle, ductile cast iron is much more flexible and elastic, due to its nodular graphite inclusions.

· Ductile Iron Pipe offers proven reliability and the quality.

· It is quick and easy installation.

· The ductile iron pipe has high pressure capability.

· Available in sizes DN80 – DN2000

· Both T Type (Push-on Joint) and K Type (Mechanical Joint) are available

· Match 100% Natural rubber / SBR / EPDM rubber gaskets

Application:

Much of the production of ductile iron is in the form of ductile cast iron pipe, used for water supply and sewerage design. Ductile iron pipe is stronger and easier to tap, requires less support and provides greater flow area compared with pipes made from other materials like PVC, concrete, polyethylene or steel.

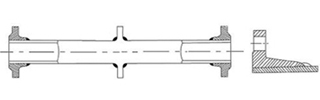

Types of Flange Pipe:

Flange pipes with screwed-on flanges, Flanged pipes with cast-on flanges, Flanged pipes with welded-on flanges are available

Flange pipes with screwed-on flanges, K9 K10 DN80-DN600, Length to be specified

Flange pipes with cast-on flanges, K12 DN1200-2000, L≤4000mm

Flange pipes with welded-on flanges, K9 K10, DN80-DN1000, Length to be specified

Nominal Diameter of Flange Pipe:

|

Nominal Diameter DN |

Body |

| ||||||||

|

k=9 |

k=10 |

k=12 |

Each Flange | |||||||

|

e mm |

kg/m |

e mm |

kg/m |

e mm |

kg/m |

PN10 |

PN16 |

PN25 |

PN40 | |

|

80 |

6 |

12.2 |

6 |

12.2 |

7 |

14.1 |

3.6 |

3.6 |

3.5 |

3.5 |

|

100 |

6.1 |

15.1 |

6.1 |

15.1 |

7.2 |

17.7 |

4.2 |

4.2 |

4.5 |

4.5 |

|

150 |

6.3 |

22.8 |

6.5 |

23.5 |

7.8 |

28 |

6.3 |

6.3 |

7.1 |

9.2 |

|

200 |

6.4 |

30.6 |

7 |

33.3 |

8.4 |

39.7 |

8.8 |

8.6 |

10.4 |

15.7 |

|

250 |

6..8 |

40.2 |

7.5 |

44.3 |

9 |

52.8 |

12 |

11.8 |

15.3 |

25.4 |

|

300 |

7.2 |

50.8 |

8 |

56.3 |

9.6 |

67.3 |

16.8 |

16.6 |

20.8 |

36.3 |

|

350 |

7.7 |

63.2 |

8.5 |

69.6 |

10.2 |

83.1 |

23 |

25.5 |

29.0 |

- |

|

400 |

8.1 |

75.5 |

9 |

83.7 |

10.8 |

100 |

26.5 |

31 |

37.4 |

- |

|

500 |

9 |

104.3 |

10 |

115.6 |

12 |

138.2 |

41 |

54 |

54.5 |

- |

|

600 |

9.9 |

137.1 |

11 |

152 |

13.2 |

181.8 |

56 |

79.8 |

79.1 |

- |

|

700 |

10.8 |

173.9 |

12 |

193 |

14.4 |

230.8 |

72.5 |

84.2 |

- |

- |

|

800 |

11.7 |

215.2 |

13 |

238.7 |

15.6 |

285.5 |

102 |

117 |

- |

- |

|

900 |

12.6 |

260.2 |

14 |

288.7 |

16.8 |

345.4 |

118.5 |

137.5 |

- |

- |

|

1000 |

13.5 |

309.3 |

15 |

343.2 |

18 |

410.6 |

135 |

169.4 |

- |

-- |

|

1200 |

15.3 |

420.1 |

17 |

466.1 |

20.4 |

557.8 |

180 |

235 |

- |

- |

|

1400 |

17.1 |

547.2 |

19 |

607.2 |

22.8 |

726.8 |

253 |

301 |

- |

- |

|

1600 |

18.9 |

690.3 |

21 |

766 |

25.2 |

916.9 |

- |

- |

- |

- |

|

1800 |

20.7 |

850.1 |

23 |

943.4 |

27.6 |

1129.3 |

- |

|

- |

- |

|

2000 |

22.5 |

1026.3 |

25 |

1139 |

30 |

1363.4 |

- |

- |

- |

- |

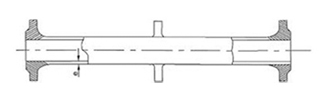

Double Flange Pipes

Double Flanged Pipes

We are involved in the manufacture and supply of the ductile iron double flanged pipe. We manufacture these with the premium quality raw materials. Our pipes ensure high durability and strength. Our range of Double Flanged Pipes caters to various industrial requirements. We offer these Double Flanged Pipes in different sizes and lengths in order to meet the various requirements of our esteemed clients.

K12

Size: DN80-1200

|

Nominal Diameter DN |

L |

Mass(kg) | |

|

Inch size end |

Metric size end | ||

|

3 |

80 |

150 |

6.8 |

|

3 |

80 |

200 |

7.5 |

|

3 |

80 |

250 |

8.2 |

|

4 |

100 |

250 |

10.8 |

|

5 |

150 |

250 |

15.4 |

|

6 |

150 |

250 |

16.3 |

|

7 |

200 |

250 |

21.5 |

|

8 |

200 |

250 |

23.0 |

|

9 |

250 |

250 |

30.0 |

|

10 |

250 |

250 |

34.5 |

|

12 |

300 |

250 |

44.0 |

|

14 |

350 |

250 |

59.0 |

|

15 |

400 |

250 |

65.0 |

|

16 |

400 |

250 |

71.0 |

|

18 |

450 |

250 |

89.5 |

|

20 |

500 |

250 |

115.0 |

|

21 |

500 |

350 |

133.0 |

|

24 |

600 |

300 |

178.0 |

|

27 |

700 |

500 |

261.8 |

|

30 |

700 |

500 |

289.0 |

|

30 |

800 |

500 |

317.0 |

|

33 |

800 |

500 |

356.0 |

|

36 |

900 |

500 |

420.0 |

|

42 |

1000 |

500 |

514.0 |

|

42 |

1100 |

500 |

575.0 |

|

48 |

1200 |

500 |

718.0 |

Photo Show of Flange Pipe:

- Q: Are ductile iron pipes suitable for industrial water systems?

- Yes, ductile iron pipes are suitable for industrial water systems. Ductile iron pipes are known for their strength, durability, and corrosion resistance, making them an ideal choice for transporting water in industrial settings. They can withstand high-pressure and heavy-duty applications, making them suitable for conveying water in large-scale industrial facilities such as power plants, factories, and chemical plants. Additionally, ductile iron pipes have the ability to handle a wide range of temperatures, making them suitable for both hot and cold water systems. Their inherent flexibility allows for easy installation and maintenance, further adding to their suitability for industrial water systems. Overall, ductile iron pipes are a reliable and cost-effective solution for industrial water transportation needs.

- Q: What is the expected joint tightness for ductile iron pipes?

- The expected joint tightness for ductile iron pipes is typically high. Ductile iron pipes are known for their strong and durable nature, making them highly resistant to leaks and joint failures. The joints in ductile iron pipes are usually designed to provide a secure and tight connection, ensuring minimal water or fluid loss. Various joint types are commonly used for ductile iron pipes, including mechanical joints, restrained joints, and push-on joints. Each of these joint types is designed to provide a reliable seal and prevent any leakage. Mechanical joints use a mechanical gland and rubber gaskets to create a tight seal. These joints require a certain level of torque during assembly to ensure proper compression and sealing. Restrained joints, on the other hand, are specifically designed to withstand external forces, such as soil movement or pressure, and maintain their tightness. These joints typically use a mechanical restraint system, such as a key-locking mechanism, to prevent joint separation. Push-on joints are the easiest to install and provide a secure seal by utilizing a rubber gasket that is compressed when the pipes are pushed together. These joints are commonly used in smaller diameter pipes where the external forces are minimal. Overall, ductile iron pipes are expected to have a high level of joint tightness, ensuring reliable and leak-free performance in various applications, including water distribution, wastewater systems, and industrial piping networks.

- Q: Can ductile iron pipe be used for gas distribution systems?

- Indeed, gas distribution systems can utilize ductile iron pipe. Ductile iron, being a robust and enduring substance, exhibits resistance to corrosion, thus rendering it suitable for subterranean applications. Its capacity to endure high pressure and furnish a dependable and enduring solution has led to its widespread employment in gas distribution systems for numerous years. Moreover, ductile iron pipes are acknowledged for their pliability, facilitating simpler installation and upkeep. Nevertheless, it is imperative to guarantee conformity with the specific requirements and standards of gas distribution systems when implementing ductile iron pipes to ensure the system's safety and efficiency.

- Q: What are the meanings of cast iron pipe wall thicknesses LA, A and B respectively?

- You are mistaken in concept. The cast iron pipe is the sort of connection method. The ductile iron pipe is classified according to the material.

- Q: Can ductile iron pipes be used in areas with high temperature variations?

- Yes, ductile iron pipes can be used in areas with high temperature variations. Ductile iron has a high resistance to thermal expansion and contraction, making it suitable for withstanding temperature fluctuations without compromising its structural integrity or performance.

- Q: What is the expected fatigue life of ductile iron pipes under cyclic loading?

- The fatigue life of ductile iron pipes under cyclic loading can vary due to factors such as the magnitude and frequency of the loading, material quality, pipe design and installation, and environmental conditions. Ductile iron possesses high strength and ductility, enabling it to withstand cyclic loading to a certain extent. However, like any material, it is susceptible to fatigue failure over time. Engineers commonly employ fatigue analysis and testing methods to estimate the expected fatigue life of ductile iron pipes. These methods involve subjecting representative samples of the pipes to controlled cyclic loading and determining the number of cycles required for failure. The results of these tests can then be used to extrapolate the expected fatigue life of the pipes under similar loading conditions. It is important to note that the expected fatigue life can significantly differ depending on the specific conditions and loading patterns experienced by the pipes in a given application. Therefore, it is crucial to consider operational demands, maintenance practices, and the overall structural integrity of the pipeline system. Additionally, adhering to appropriate design standards and guidelines, along with regular inspection and maintenance, can help enhance the fatigue life of ductile iron pipes. In conclusion, while providing a specific value for the expected fatigue life of ductile iron pipes under cyclic loading is challenging, engineers can estimate it through fatigue analysis and testing methods. Considering various factors and maintaining the pipes properly is essential to ensure their longevity and prevent potential failures.

- Q: Can ductile iron pipes be used in areas with high soil settlement?

- Yes, ductile iron pipes can be used in areas with high soil settlement. Ductile iron pipes have excellent strength and flexibility, which allows them to withstand the settlement and movement of the surrounding soil without causing significant damage or failure.

- Q: Can ductile iron pipes be used in areas with high soil liquefaction potential?

- Ductile iron pipes can be used in areas with high soil liquefaction potential, but certain precautions and considerations need to be taken into account. Soil liquefaction is a phenomenon in which saturated soil temporarily loses its strength and behaves like a liquid during an earthquake or other seismic events. Ductile iron pipes are known for their strength, durability, and resistance to external loads, making them suitable for various applications, including water and wastewater transportation. However, when it comes to areas with high soil liquefaction potential, additional measures should be considered to ensure the pipes' performance and integrity. One crucial factor to consider is the pipe's installation depth. Ductile iron pipes should be installed at a sufficient depth below the ground surface to minimize the effects of soil liquefaction. The depth will vary depending on soil conditions and the level of seismic activity in the area. Consulting with geotechnical engineers and following local building codes and regulations is essential to determine the appropriate installation depth. Furthermore, proper backfill materials and compaction techniques must be employed during the pipe installation process. Using granular materials, such as crushed stone or gravel, for backfill can help improve the soil's stability and reduce the potential for liquefaction. Adequate compaction of the backfill is also necessary to ensure the pipes' stability and prevent settlement or movement during seismic events. Moreover, it is recommended to use flexible joints, such as restrained joints or push-on joints, when installing ductile iron pipes in areas prone to soil liquefaction. These joints allow for some movement and flexibility, which can help absorb the ground's movement during an earthquake, reducing the stress on the pipes and minimizing the risk of damage. Regular inspection and maintenance of the ductile iron pipes are crucial in high soil liquefaction potential areas. Monitoring for any signs of movement, settling, or damage should be conducted, and any necessary repairs or reinforcements should be promptly addressed to ensure the pipes' continued performance and safety. In conclusion, ductile iron pipes can be used in areas with high soil liquefaction potential, but careful consideration of installation depth, proper backfill materials and compaction, the use of flexible joints, and regular maintenance are crucial to ensuring their optimal performance and longevity. Consulting with geotechnical engineers and following local building codes and regulations is highly recommended to ensure the pipes' suitability in such areas.

- Q: What do ductile iron pipes need to connect with three? Can I contact it directly?

- Old craft1. dozen to lead lead; cut into strips, with a file play in the interface2. use expanded cement with asbestos3 use the asphalt

- Q: Ductile iron pipe joint leakage

- The main reason for the leakage is that the installation is not in place, resulting in the loss of the apron. Sealed with cement or pipe head Hough section. Recommend the use of Hough section fast and convenient, and there is no menace from the rear.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1958 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East, Africa, South Asia, Eastern Asia |

| Company Certifications | ISO 9001:2008;ISO2531:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 3000 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Flange Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Metric Ton pc

- Supply Capability:

- 300000 Metric Tons per Year pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords