Duct Iron Pipe DI Pipe ISO 2531 DN 700-1000mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

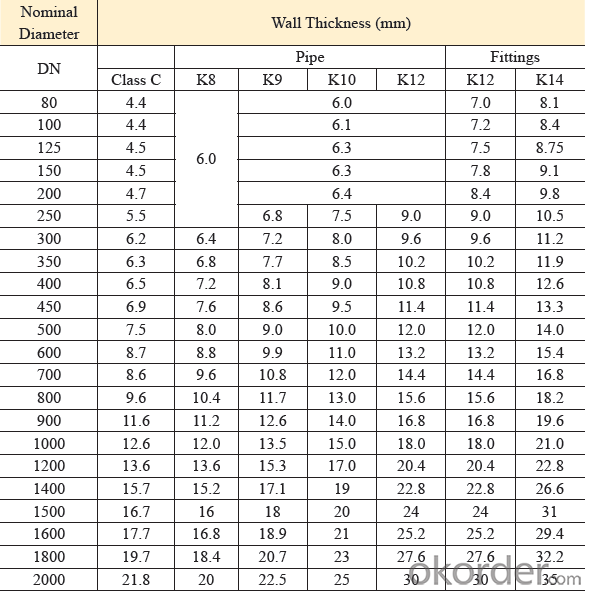

Specification:

1. size : DN80-DN2000 available with PN16 or PN10 or PN25 flanges

2.Standard : ISO2531/EN545/EN598/AWWA standard

3. WRAS Potable Water FBE Internal Lining

4.Material : Ductile iron

5.Technical: Casting

6. Type: Socket / flange PN10 / PN16 / PN25

7. Length=6m, 5.8m

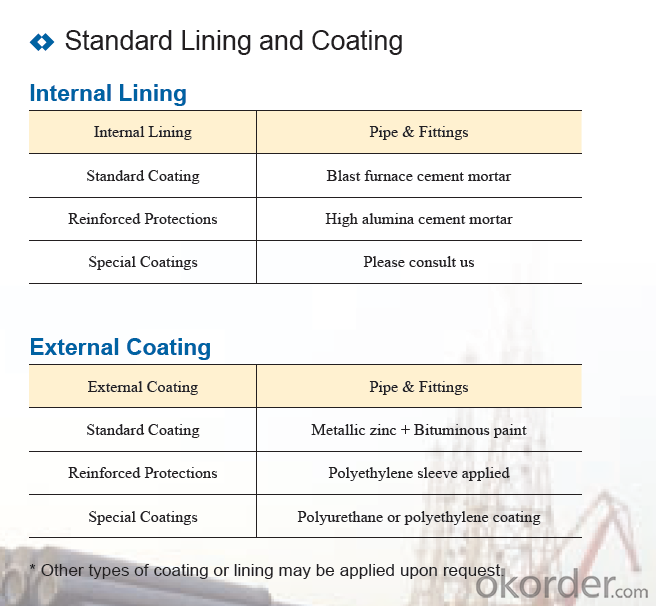

8. Coating: Fusion bonded epoxy to 300 microns Dry Film Thickness

Portland cement lining internally and zinc-rich paint with not less than 70 microns bitumen externally

Quality:

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

Standard Lining and Coating:

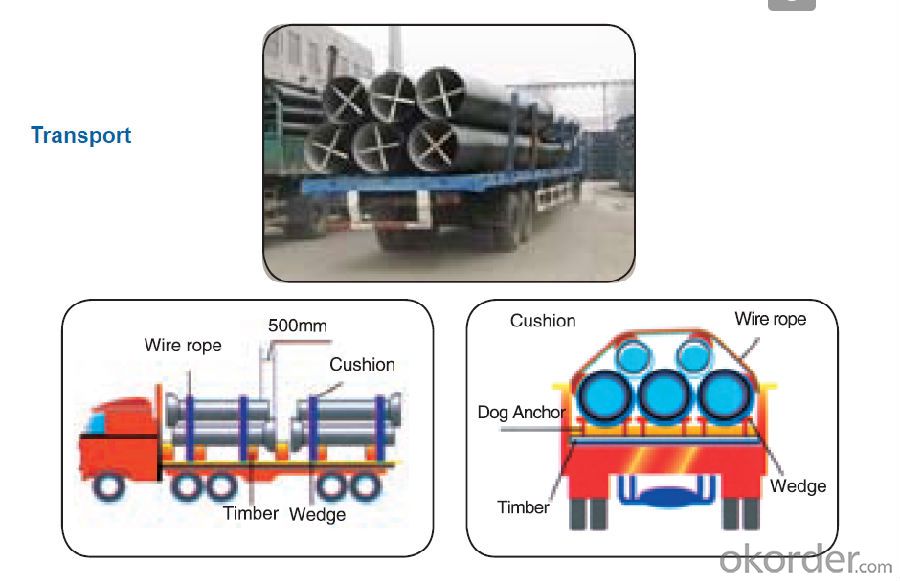

Transport:

- Q: QT400-10 nodular cast iron requires hardness of HRC47~51. Why can't quench hardness be reached?

- Quenching temperature: when the silicon content of nodular cast iron is 2.0-3.0%, the quenching temperature is 860-900 DEG C, the silicon content is low, and the upper limit is taken when the lower limit is high.2. holding time: because of the consideration of diffusion graphite cast iron, alloy steel is therefore the holding time, holding time longer than carbon steel.3. oil quenching.

- Q: Can ductile iron pipes be used for geothermal systems?

- Yes, ductile iron pipes can be used for geothermal systems. Ductile iron pipes have excellent strength and durability, making them suitable for handling the high temperatures and pressures typically encountered in geothermal systems. Their corrosion resistance and flexibility also make them a reliable choice for transporting geothermal fluid efficiently.

- Q: What is the composition of ductile iron pipes?

- Ductile iron pipes are primarily composed of iron, with small amounts of carbon, silicon, manganese, and trace elements such as sulfur and phosphorus.

- Q: What are the different methods for tapping ductile iron pipe?

- Tapping ductile iron pipe can be done in several different ways, depending on the project's specific needs. Some commonly used methods include: 1. Mechanical Tapping: To create a hole in the ductile iron pipe, a mechanical tapping machine is employed. Equipped with a rotating cutting tool, the machine easily cuts through the pipe wall, resulting in a clean hole. This method is ideal for smaller diameter pipes and is both quick and efficient. 2. Hot Tapping: While the ductile iron pipe is still in service and under pressure, hot tapping involves creating a hole. To ensure safety and maintain the pipe's integrity, specialized equipment and expertise are required. Hot tapping is commonly used when shutting down the pipeline for maintenance or repair work is impractical or not feasible. 3. Electrofusion Tapping: For larger diameter pipes, electrofusion tapping is a suitable method. It involves using an electrofusion saddle and fitting to create a branch connection on the ductile iron pipe. By welding a fitting onto the pipe with an electrofusion machine, a secure and leak-proof connection is achieved. This method can be used for both water and gas applications. 4. Saddle Tapping: A cost-effective and simple method for smaller diameter pipes is saddle tapping. It involves attaching a saddle or clamp onto the ductile iron pipe and drilling a hole through it. The saddle is then equipped with a threaded outlet to connect a branch line. 5. Split Sleeve Tapping: For larger diameter pipes, split sleeve tapping is commonly used. This method requires cutting a section out of the ductile iron pipe and installing a split sleeve over the cut. By bolting the split sleeve together, a secure and watertight connection is established. It is suitable for both water and gas applications. When selecting the tapping method, it is crucial to consider factors like pipe size, pressure rating, required branch connection, and project-specific requirements. Consulting a professional engineer or tapping specialist is highly recommended to ensure the correct method is used for tapping ductile iron pipe.

- Q: How does ductile iron pipe perform in areas with high soil erosion?

- Ductile iron pipe performs well in areas with high soil erosion due to its inherent strength and durability. Its thick walls and strong composition make it resistant to external pressures, including the erosive forces of soil. The pipe's ability to withstand the effects of soil erosion helps ensure its long-term performance and reliability in such challenging environments.

- Q: How does the white iron appear in the case of ductile iron?

- The addition of 0.2% SiC in the raw iron water can effectively reduce the chill.

- Q: Can ductile iron pipe be used for oil and gas pipelines?

- Yes, ductile iron pipe can be used for oil and gas pipelines. Its high strength, durability, and corrosion resistance make it suitable for transporting oil and gas over long distances. Additionally, its flexibility and ability to withstand high pressures and temperatures make it a reliable choice for such applications.

- Q: How does ductile iron pipe perform in areas with high soil consolidation?

- Ductile iron pipe performs well in areas with high soil consolidation due to its inherent strength and durability. The pipe's flexibility allows it to withstand ground movement, settlement, and consolidation without compromising its structural integrity. Additionally, ductile iron is resistant to corrosion, making it a suitable choice for areas with varying soil conditions.

- Q: Can ductile iron pipe be used for marine and offshore applications?

- Yes, ductile iron pipe can be used for marine and offshore applications. Ductile iron is known for its high strength and durability, making it suitable for various environments, including those with exposure to saltwater and harsh conditions. It is commonly used in marine and offshore projects due to its resistance to corrosion, impact, and pressure. Additionally, ductile iron pipes have proven to be cost-effective and reliable for transporting fluids in these challenging environments.

- Q: Are ductile iron pipes compatible with other pipe materials?

- Yes, ductile iron pipes are generally compatible with other pipe materials. Ductile iron pipes have a high level of flexibility and strength, making them suitable for connecting with different pipe materials such as PVC, HDPE, and steel. Transition fittings are commonly used to connect ductile iron pipes to other materials, ensuring a secure and leak-free joint. It is important to adhere to industry standards and guidelines when connecting different pipe materials to ensure compatibility and maintain the integrity of the pipeline system.

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 700-1000mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords