Duct Iron Pipe DI Pipe ISO 2531 DN 350-600mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

1. size : DN80-DN2000 available with PN16 or PN10 or PN25 flanges

2.Standard : ISO2531/EN545/EN598/AWWA standard

3. WRAS Potable Water FBE Internal Lining

4.Material : Ductile iron

5.Technical: Casting

6. Type: Socket / flange PN10 / PN16 / PN25

7. Length=6m, 5.8m

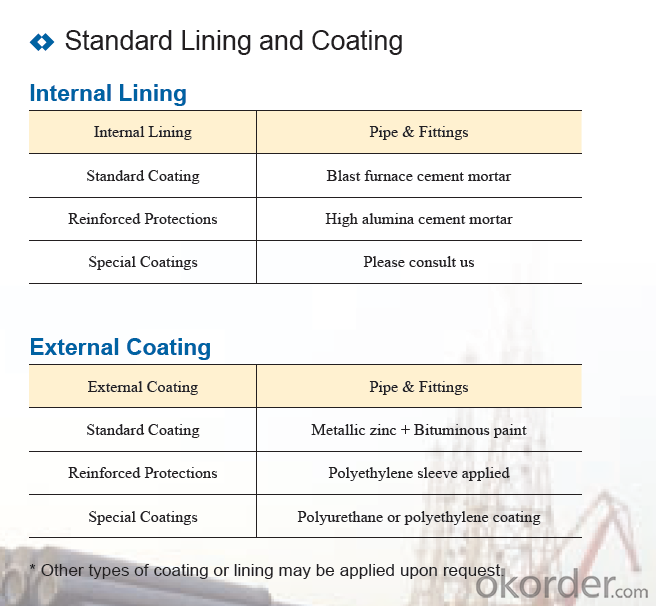

8. Coating: Fusion bonded epoxy to 300 microns Dry Film Thickness

Portland cement lining internally and zinc-rich paint with not less than 70 microns bitumen externally

Quality:

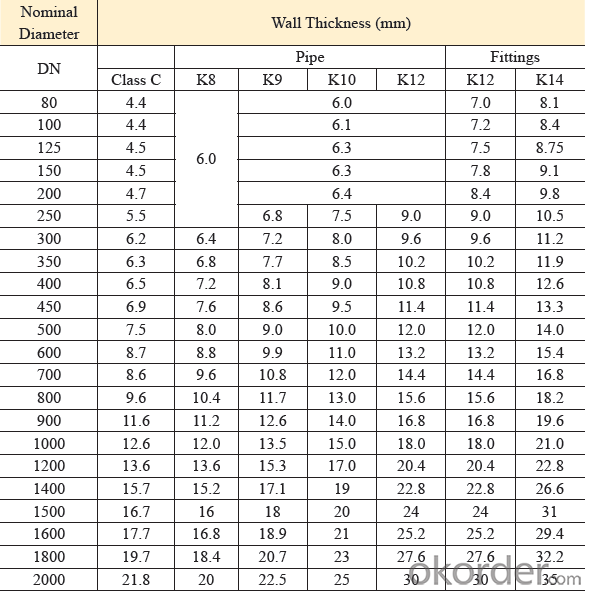

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

Standard Lining and Coating:

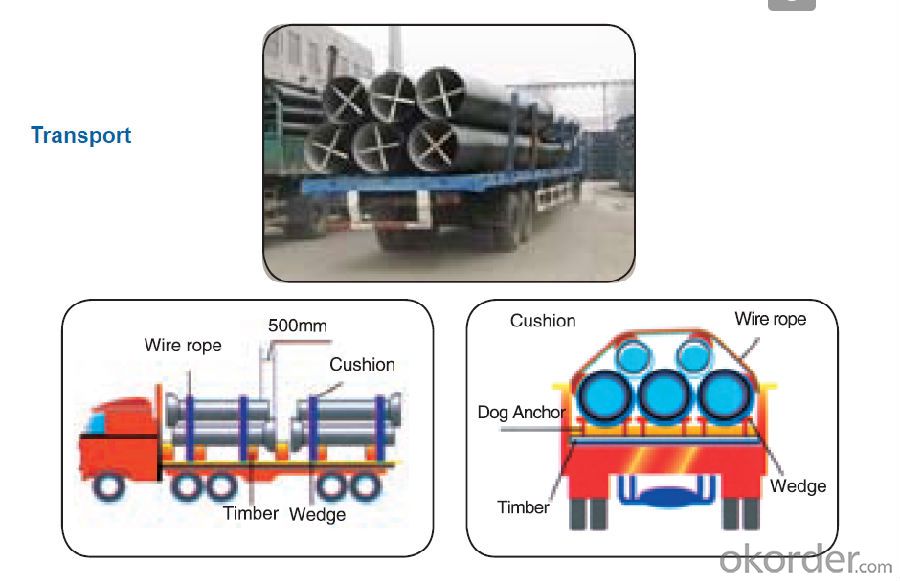

Transport:

- Q: Ductile cast iron can replace copper sleeve

- Although the ductile cast iron with lubrication, but no lubrication or copper sleeve, Rongchang graphite copper sleeve, with self lubrication with high strength copper alloy (CuZn25Al5, CuZn24Al6Fe3Mn4) as the basic material, according to the use conditions according to a certain proportion in the work surface processing hole and fill in the solid lubricant, high strength copper alloy provide a high bearing capacity and solid lubricant can form low friction.

- Q: What is the expected leakage rate for ductile iron pipes?

- The expected leakage rate for ductile iron pipes can vary depending on various factors such as the age, condition, and installation methods of the pipes, as well as the quality of the materials used. However, ductile iron pipes are generally known for their durability and low leakage rates compared to other pipe materials. According to industry standards and research studies, the expected leakage rate for well-maintained ductile iron pipes can be as low as 0.1% per year. This means that, on average, less than 1 liter of water per meter of pipe length may leak annually. However, it is important to note that this is an average figure and actual leakage rates can vary. Regular maintenance and inspections play a crucial role in minimizing leaks and ensuring the longevity of ductile iron pipes. Additionally, proper installation techniques, such as using effective jointing methods and adequate bedding and backfill materials, can also contribute to reducing leakage rates. It is recommended to consult with industry professionals and adhere to applicable standards and regulations to determine the expected leakage rate for specific ductile iron pipe installations.

- Q: QT400-10 nodular cast iron requires hardness of HRC47~51. Why can't quench hardness be reached?

- QT400-10 shall ensure sufficient pearlite in the casting state, at least half of the pearlite. This is done with the temperature, time, and water. But if it is big, the heart hardness will not go up.

- Q: Can ductile iron pipes be used for stormwater management systems?

- Yes, ductile iron pipes can be used for stormwater management systems. Ductile iron pipes are known for their strength, durability, and corrosion resistance, making them suitable for handling stormwater runoff. They can effectively transport large volumes of water and withstand the pressure and impact associated with stormwater management.

- Q: Can ductile iron pipes be used for slurry transportation?

- Yes, ductile iron pipes can be used for slurry transportation. Ductile iron pipes are known for their strength and durability, which makes them suitable for transporting various types of fluids, including slurry. They have the ability to withstand the abrasive nature of slurry and can effectively handle the pressure and flow requirements associated with slurry transportation.

- Q: Are ductile iron pipes recyclable?

- Yes, ductile iron pipes are recyclable. Ductile iron is a type of cast iron that has superior strength and durability, making it an excellent choice for various applications, including water and sewage systems. When these pipes reach the end of their lifespan, they can be recycled and reused. The recycling process involves melting down the ductile iron pipes and using the molten metal to produce new pipes or other iron-based products. Recycling ductile iron pipes not only helps to conserve natural resources but also reduces the amount of waste that goes into landfills. Therefore, ductile iron pipes are considered a sustainable and environmentally friendly option for piping systems.

- Q: What is ductile iron?

- Ductile iron, after being treated with either magnesium or cerium, undergoes an improvement in its mechanical properties. This particular type of cast iron earns the name "ductile" due to its higher degree of ductility in comparison to other cast iron varieties. Ductility pertains to a material's capacity to stretch or deform without breaking. This quality renders ductile iron particularly ideal for applications that demand both high strength and resistance to wear and tear, such as pipes, automotive components, and machinery parts. The inclusion of magnesium or cerium during the manufacturing process aids in the formation of graphite within the iron's structure, contributing to its distinctive properties. This graphite formation serves to enhance the iron's flexibility and reduce its brittleness, enabling it to absorb shock and vibrations without fracturing. As a whole, ductile iron presents a fine balance between the strength of cast iron and the flexibility of steel, thereby establishing itself as a versatile material well-suited for diverse industrial applications.

- Q: What does "K8" mean in ductile iron pipe grades?

- K9 is GB, K10 is specially customized, K8... Strictly speaking, it is not up to standard, standard length, wall thickness and so on.. Many workshops, grades of factory products, such as K9, standard length 6.15M, K8 is 6M, wall thickness from the beginning of DN100, are thin on the point.

- Q: How are ductile iron pipes protected against external impact or loading?

- Ductile iron pipes undergo various methods and measures to safeguard them against external impact or loading, guaranteeing their durability and integrity. Several common approaches are employed to protect ductile iron pipes, including: 1. Adequate Thickness and Strength: Ductile iron pipes are designed with ample wall thickness and high strength to withstand external loads and impacts. This design feature ensures that the pipes can endure heavy loads without deforming or cracking. 2. Implementation of Coatings: Ductile iron pipes are typically coated with protective layers to create an additional barrier against external impact. These coatings may comprise cement mortar lining, polyethylene encasement, or epoxy coatings. They not only grant impact resistance but also safeguard against corrosion. 3. Utilization of Proper Bedding and Backfilling Techniques: Proper techniques for bedding and backfilling are crucial in protecting ductile iron pipes from external loads. The correct placement of pipes within suitable materials, such as compacted granular bedding and backfill, helps distribute external loads evenly and minimizes the risk of pipe damage. 4. Consideration of Trench Design: The design of the trench in which ductile iron pipes are installed plays a vital role in safeguarding them against external impact. The dimensions of the trench, slope stability, and proper compaction of the backfill are all taken into account to reduce the likelihood of damage caused by external loads. 5. Implementation of Effective Pipe Layout and Support: Appropriate pipe layout and support are essential for protecting ductile iron pipes from external impact. Sufficient support mechanisms, including thrust blocks, pipe anchors, and pipe restraints, are utilized to absorb and distribute external loads, preventing any damage to the pipes. 6. Installation of Protective Structures: In areas where the risk of external impact is higher, additional protective structures are installed to safeguard ductile iron pipes. These structures may include concrete encasements, bollards, or reinforced concrete slabs, which act as physical barriers against potential impacts. In conclusion, a combination of factors, including pipe strength, coatings, proper installation techniques, and support measures, work together to ensure the protection of ductile iron pipes against external impact or loading. These measures enhance the longevity and reliability of the pipes, guaranteeing efficient performance in various applications.

- Q: Can ductile iron pipes be used in areas with high levels of groundwater contamination?

- Areas with high levels of groundwater contamination can make use of ductile iron pipes. Ductile iron, known for its strength and durability, is resistant to corrosion, making it suitable for various environments, including those with contaminated groundwater. It provides a high level of resistance to chemicals and can withstand the corrosive effects of contaminants that may be present in the groundwater. Furthermore, ductile iron pipes possess a protective lining, further enhancing their corrosion resistance. However, it is important to consider that the suitability of ductile iron pipes in such areas relies on the specific nature and concentration of contaminants in the groundwater. Seeking advice from experts and adhering to local regulations and industry standards is essential to ensure the proper selection and installation of pipes in areas with high levels of groundwater contamination.

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 350-600mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords