Duct Iron Pipe DI Pipe ISO 2531 DN 1100-2000mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

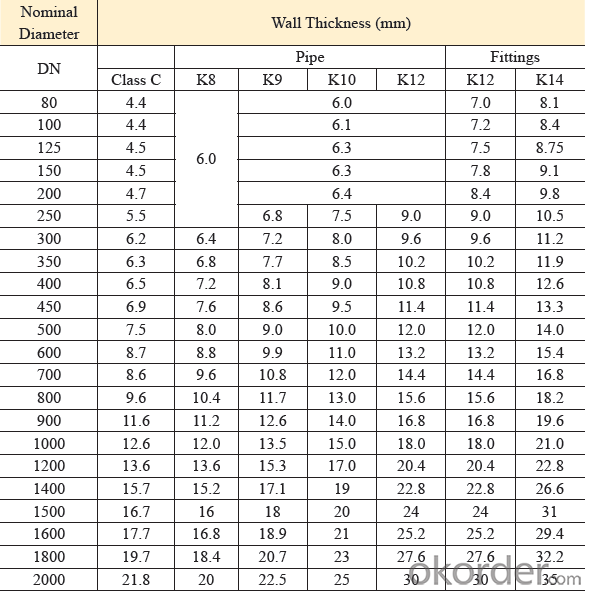

Specification:

1. size : DN80-DN2000 available with PN16 or PN10 or PN25 flanges

2.Standard : ISO2531/EN545/EN598/AWWA standard

3. WRAS Potable Water FBE Internal Lining

4.Material : Ductile iron

5.Technical: Casting

6. Type: Socket / flange PN10 / PN16 / PN25

7. Length=6m, 5.8m

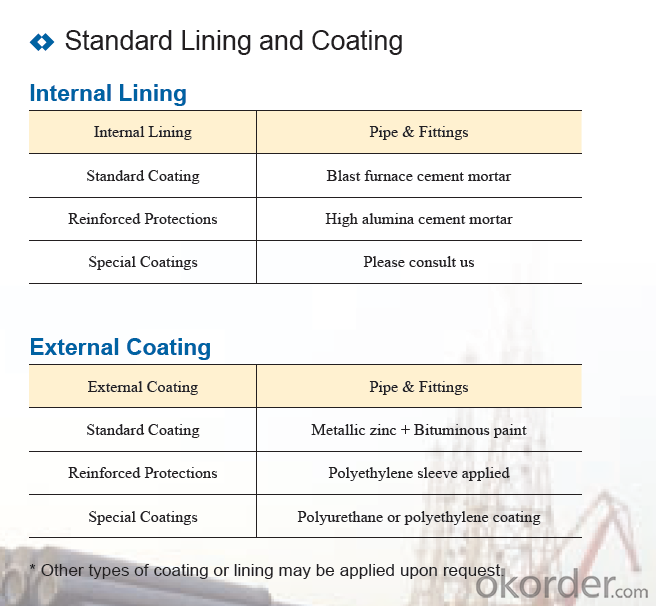

8. Coating: Fusion bonded epoxy to 300 microns Dry Film Thickness

Portland cement lining internally and zinc-rich paint with not less than 70 microns bitumen externally

Quality:

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

Standard Lining and Coating:

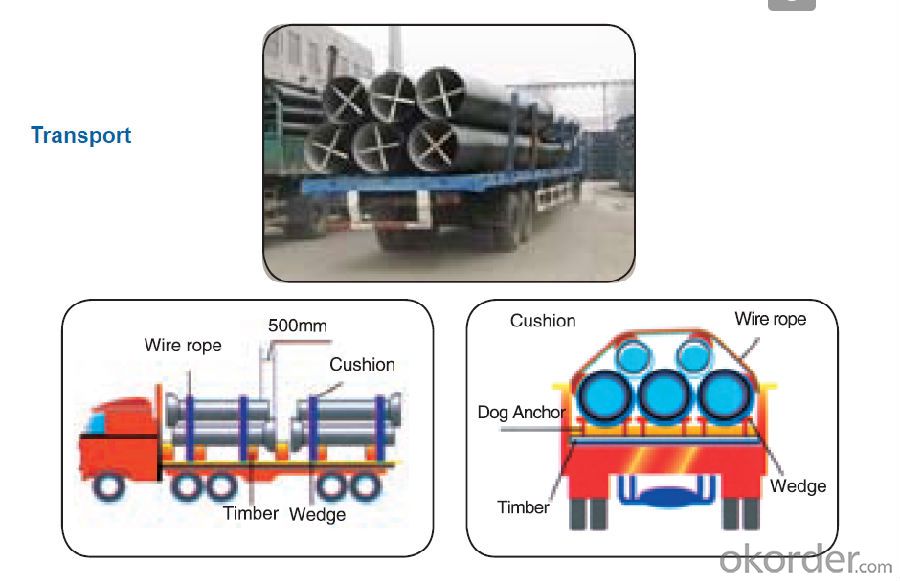

Transport:

- Q: What is the maximum pressure rating for ductile iron pipe?

- The maximum pressure rating for ductile iron pipe typically ranges from 350 to 500 psi, depending on the diameter and wall thickness of the pipe. However, it is always recommended to consult the manufacturer's specifications for accurate and specific pressure ratings.

- Q: How does ductile iron pipe perform in seismic conditions?

- Seismic conditions are where ductile iron pipe truly shines. This type of pipe has gained a reputation for its outstanding performance in such situations, making it the go-to choice for underground water and wastewater systems, particularly in earthquake-prone areas. The remarkable strength and flexibility of ductile iron pipe make it highly resistant to seismic forces. It can withstand the ground movements and vibrations caused by earthquakes without suffering significant damage or failure. The secret lies in its unique composition, which consists of a high iron content combined with small amounts of carbon and other alloying elements. The crucial advantage of ductile iron pipe in seismic conditions is its ability to absorb and dissipate seismic energy through its inherent flexibility. When the ground shifts during an earthquake, the pipe can adapt and deform slightly to accommodate the movement. This minimizes stress concentrations and reduces the risk of fractures. Furthermore, the joint integrity of ductile iron pipe is exceptional, a vital characteristic in seismic conditions. The joints are designed to offer maximum strength and resistance against external forces, including seismic activity. Different joint types, such as push-on, mechanical, and restrained joints, are available to suit various seismic requirements and installation conditions. Not only does ductile iron pipe possess impressive mechanical properties, but it also offers long-term corrosion resistance. Typically, the pipe is lined with a cement mortar or a protective coating, acting as a barrier against corrosive elements present in the soil or water. This corrosion resistance ensures the pipe's structural integrity and longevity, even in regions with high seismic activity. Overall, ductile iron pipe has a proven track record of exceptional performance in seismic conditions. Its strength, flexibility, joint integrity, and corrosion resistance make it a reliable choice for underground infrastructure, providing secure and efficient water and wastewater systems in areas prone to earthquakes.

- Q: Maximum pipe diameter of ductile iron pipe

- The maximum diameter of ball milling cast iron pipe can be DN3000.. For long pressure pipeline, the performance of ball milling cast iron pipe is better than that of PCCP tube, and the performance is reliable, safe and stable!

- Q: What is the weight of ductile iron pipes compared to other materials?

- Ductile iron pipes are generally heavier than other commonly used materials such as PVC or HDPE pipes.

- Q: What are the common methods for flow control in ductile iron pipes?

- The common methods for flow control in ductile iron pipes include the use of valves, such as gate valves, butterfly valves, and check valves. These valves are designed to regulate the flow of water or other fluids in the pipe, allowing for control and adjustment of the flow rate. Additionally, flow control can also be achieved through the use of flow meters and flow regulators, which monitor and regulate the flow of fluids through the pipe system.

- Q: What are the recommended bedding and backfill materials for ductile iron pipe?

- The recommended bedding and backfill materials for ductile iron pipe include a combination of granular materials such as sand, gravel, or crushed stone. These materials provide support and stability to the pipe, ensuring proper alignment and preventing damage during installation and operation. For bedding, a layer of sand is typically used to create a uniform and level surface for the pipe to rest on. This helps distribute the load evenly along the pipe's length and reduces the potential for stress concentration. Backfill material is used to fill the remaining space around the pipe once it is properly bedded. It is crucial to select a material that offers good compaction and drainage properties to prevent settling and potential damage to the pipe. Commonly used backfill materials include crushed stone or gravel, which provide stability and allow for proper compaction. It is important to follow the recommendations of the pipe manufacturer and any relevant industry standards when selecting bedding and backfill materials for ductile iron pipe. These materials should meet the specified size and quality requirements to ensure the long-term performance and durability of the pipe system. Additionally, local regulations and soil conditions should also be taken into consideration when determining the appropriate bedding and backfill materials for ductile iron pipe installations.

- Q: How do ductile iron pipes handle ground settlement near construction sites?

- Ductile iron pipes are highly resilient and can withstand ground settlement near construction sites. Due to their flexible nature, these pipes can accommodate small movements and settlement without incurring significant damage or failure. The ductility of the material allows the pipes to bend and adjust to the changing ground conditions, ensuring their integrity and minimizing the risk of leaks or breakage. Additionally, the strong and durable properties of ductile iron make it a reliable choice for underground infrastructure, providing long-term stability even in challenging environments.

- Q: The difference between ductile iron pipe and steel pipe used in pipe jacking

- The casting processes of nodular cast iron pipes are continuous casting, hot die casting and water-cooled centrifugal casting, in which water cooling is the most advanced process in the world,

- Q: What is the maximum temperature that ductile iron pipes can handle?

- The maximum temperature that ductile iron pipes can handle depends on various factors such as the specific grade of ductile iron, the specific application, and the duration of exposure to elevated temperatures. Generally, ductile iron pipes have a maximum recommended operating temperature of around 400-450 degrees Fahrenheit (205-232 degrees Celsius). However, it is important to consult the manufacturer's specifications and guidelines for the specific product being used as different grades and manufacturers may have slightly different temperature limits. It is also crucial to consider the thermal expansion and contraction characteristics of ductile iron pipes to avoid any potential issues in high-temperature environments.

- Q: What is the expected joint performance of ductile iron pipes?

- The expected joint performance of ductile iron pipes is generally considered to be excellent. Ductile iron pipes are known for their high durability and strength, making them suitable for various applications such as water distribution, sewer systems, and industrial pipelines. One of the key aspects of joint performance in ductile iron pipes is their ability to withstand external loads and pressure. The joints in ductile iron pipes are typically designed to provide a tight and secure connection, ensuring minimal leakage and long-term structural integrity. This is achieved through various joint types, including push-on joints, mechanical joints, and restrained joints. Push-on joints are commonly used in ductile iron pipes and allow for easy installation without the need for special tools or equipment. These joints utilize a rubber gasket that provides a watertight seal, preventing any leakage. Mechanical joints, on the other hand, involve the use of mechanical devices such as bolts and nuts to create a rigid connection between the pipes. This type of joint provides additional strength and resistance against external forces. In terms of performance, ductile iron pipes have been extensively tested and proven to meet or exceed industry standards for pressure and bending strength. They have high resistance to corrosion, which ensures a long service life, and are also less susceptible to damage from ground movements or vibrations. These properties contribute to the overall joint performance of ductile iron pipes, ensuring reliable and efficient operation in various infrastructure systems. Overall, when installed and maintained properly, ductile iron pipes exhibit excellent joint performance, providing a reliable and durable solution for various applications in the water and wastewater industry.

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 1100-2000mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords