Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm PN 25

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

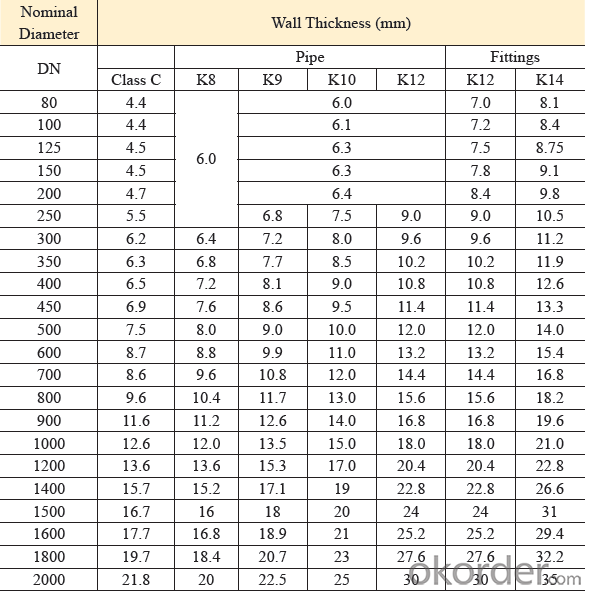

Specification:

1. size : DN80-DN2000 available with PN16 or PN10 or PN25 flanges

2.Standard : ISO2531/EN545/EN598/AWWA standard

3. WRAS Potable Water FBE Internal Lining

4.Material : Ductile iron

5.Technical: Casting

6. Type: Socket / flange PN10 / PN16 / PN25

7. Length=6m, 5.8m

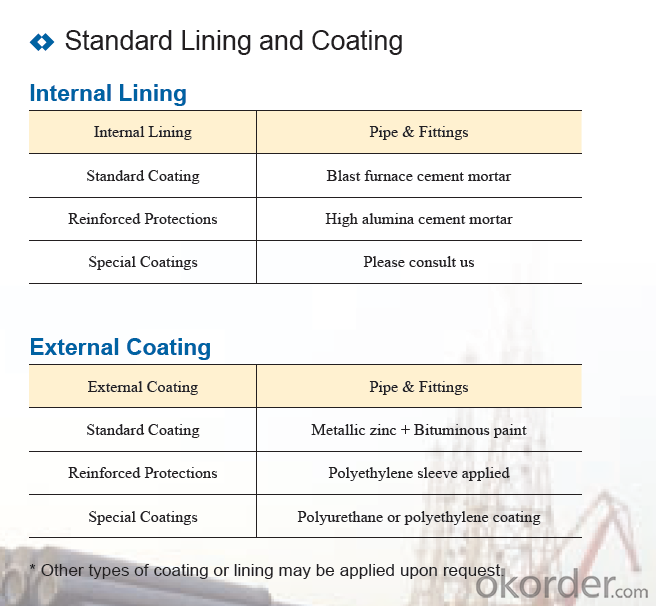

8. Coating: Fusion bonded epoxy to 300 microns Dry Film Thickness

Portland cement lining internally and zinc-rich paint with not less than 70 microns bitumen externally

Quality:

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

Standard Lining and Coating:

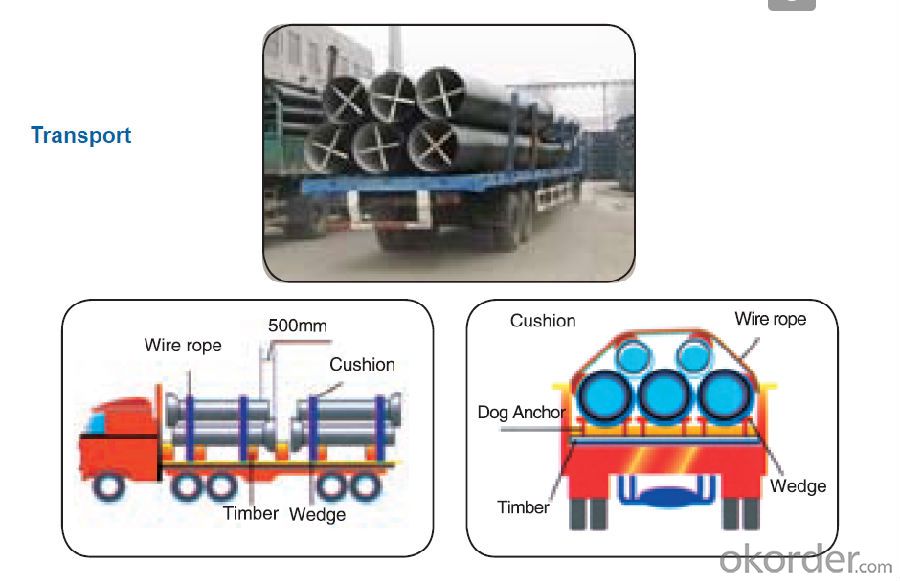

Transport:

- Q: What is the internal lining used in ductile iron pipes?

- The internal lining used in ductile iron pipes is typically a cement mortar lining.

- Q: Can ductile iron pipes be used for water distribution networks in rural areas?

- Yes, ductile iron pipes can be used for water distribution networks in rural areas. Ductile iron pipes are known for their high strength and durability, making them suitable for various applications, including water distribution. They have excellent resistance to external loads and pressure, making them ideal for underground installations. In rural areas where the water distribution network may be subjected to harsh environmental conditions or agricultural activities, ductile iron pipes can withstand external forces and resist corrosion better than other materials. They are also less prone to cracking or leaking, ensuring a reliable water supply for rural communities. Moreover, ductile iron pipes have a long service life, often exceeding 100 years. This makes them a cost-effective choice for rural water distribution networks, as they require minimal maintenance and replacement over time. However, it is important to consider other factors such as the availability of ductile iron pipes in the area, the cost of installation, and the technical expertise required for their installation and maintenance. Additionally, local regulations and standards should be followed to ensure compliance and safety. Overall, ductile iron pipes can be a suitable and reliable option for water distribution networks in rural areas, providing a long-lasting and efficient solution for delivering clean water to communities.

- Q: What are the typical joint restraint requirements for ductile iron pipes?

- The typical joint restraint requirements for ductile iron pipes involve the use of mechanical joint restraints, such as thrust blocks or tie rods, to prevent the pipe from separating or moving under internal pressure or external forces. These restraints ensure the stability and integrity of the pipeline system.

- Q: The benefits of ductile iron castings

- Its performance is close to carbon steel, but it has good casting performance, easy molding, better machinability than cast steel, better heat resistance, corrosion resistance and wear resistance than steel. And a very important one: cheap.

- Q: What are the different types of restrained joints for ductile iron pipe?

- There are several different types of restrained joints for ductile iron pipe. These joints are designed to prevent pipe separation or movement due to internal pressure, external forces, or ground movement. Some of the commonly used restrained joints for ductile iron pipe include: 1. Mechanical Restrained Joint: This type of joint uses mechanical devices such as bolts, nuts, and gaskets to hold the pipe in place. The joint is typically made up of a gland, a gland follower, and a restraint ring. The gland and gland follower compress the gasket against the pipe, while the restraint ring provides additional support and resistance against movement. 2. Push-on Restrained Joint: This joint utilizes a rubber gasket that is compressed when the two pipe ends are pushed together. The gasket provides a tight seal and also acts as a restraint against movement. Some push-on restrained joints also include additional mechanical devices to enhance the restraint capability. 3. Restrained Flange Joint: This type of joint combines the features of a flanged joint and a restrained joint. It consists of a flanged pipe end that is bolted to a flange on another pipe or fitting. The bolts and nuts provide the mechanical restraint, while the flange connection ensures a secure and leak-free joint. 4. Restrained Coupling Joint: This joint is a variation of the mechanical restrained joint. It utilizes a coupling that is bolted or clamped around the pipe ends, providing the necessary restraint. The coupling may also have a gasket to ensure a tight seal. 5. Restrained Socket Joint: This joint is similar to the push-on restrained joint, but it includes additional mechanical devices to enhance the restraint capability. The socket end of the pipe is typically designed to receive a pipe spigot, which is then secured using bolts, clamps, or other mechanical devices. These different types of restrained joints for ductile iron pipe offer varying levels of restraint and are selected based on the specific requirements of the application. They ensure the integrity and stability of the pipeline system, reducing the risk of leaks, pipe separation, or movement.

- Q: Can ductile iron pipe be used for industrial process piping?

- Indeed, industrial process piping can make use of ductile iron pipe. Renowned for its robustness, longevity, and ability to withstand corrosion, ductile iron pipe proves itself as an appropriate selection for diverse industrial functions. It boasts the capability to manage high-pressure systems and commonly finds application in sectors like water and wastewater treatment, oil and gas, chemical processing, and power generation. Moreover, ductile iron pipe offers ease of installation and an extensive lifespan, thus rendering it a cost-efficient choice for industrial process piping.

- Q: What is the K9 standard pressure for ductile iron pipes?

- Ductile iron pipe is a kind of cast iron. It is an alloy of iron, carbon and silicon. Graphite is exist in spherical form, usually graphite size is 6-7, casting spheroidization grade control requirements for 1-3 quality (spheroidization rate greater than 80%), so the mechanical properties of the material itself has been improved, has the essence of iron, steel performance.

- Q: What is the maximum temperature that ductile iron pipe can handle?

- The maximum temperature that ductile iron pipe can handle typically ranges between 350-400 degrees Fahrenheit.

- Q: What is the typical weight of ductile iron pipes?

- The typical weight of ductile iron pipes can vary depending on their size and thickness. However, as a general guideline, ductile iron pipes commonly range in weight from around 1 pound per foot for smaller diameter pipes to several hundred pounds per foot for larger diameter pipes. The weight of ductile iron pipes is determined by factors such as the pipe's dimensions, the thickness of its walls, and the specific requirements of the intended application. It is important to note that these weights are approximate and can vary based on the specific manufacturer and product specifications.

- Q: Can ductile iron pipes be used for firefighting systems?

- Ductile iron pipes are capable of being utilized in firefighting systems. This material, known for its strength and resilience, can withstand intense pressures and extreme temperatures, thereby making it a suitable option for transporting water in such systems. Moreover, the pipes' resistance to corrosion and ability to handle external loads guarantee their long-term dependability and effectiveness. Furthermore, ductile iron pipes possess exceptional fire-resistant qualities, as they are non-combustible, do not emit harmful fumes, and do not contribute to the propagation of fire. Consequently, due to their robustness, durability, and fire resistance, ductile iron pipes are widely chosen and trusted for firefighting systems.

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm PN 25

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords