Ductile Iron Pipe Self Anchor Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meter m

- Supply Capability:

- 250000 Ton Per Year m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

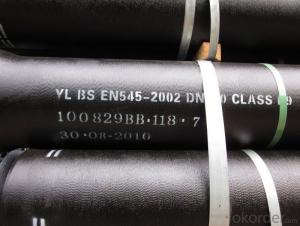

General Introduction & Specifications of Ductile Iron Pipe Self Anchor Type

Pipes according to ISO2531/EN545

Self Anchor Type

Size: DN80-DN2000

Effective length: 6m/pc or 5.7m/pc or 5.5m/pc

Internal lining: cement mortar lining comply with ISO4179

External coating: sprayed metallic Zinc coating (min.130g/m2) according to ISO8179 + bitumen painting (min.70μm) according to BS3416.

Gasket: Matched 100% natural rubber gasket in accordance with ISO4633.

Applications of Ductile Iron Pipe Self Anchor Type

Pipelines transferring portable/sewage water or gas will be greatly influenced by the chemical and physical property of soil. Things will become more serious when pipes are joined to be a long and continuous electrify entity. Thanks to its joint sealed by insulating rubber gasket every 4-6 meters, ductile cast iron pipe obtained a high resistance to corrosion caused by electric current.

Plenty ductile of cast iron pipelines which have been laying underground for over 100 years are still working in good condition nowadays.

Other Properties of Ductile Iron Pipe Self Anchor Type

Our ductile cast iron pipe are made in strict accordance with the relevant international standard and European standard. Zinc coating of CNBM pipes conforms to ISO8179, the minimum zinc coating per square meter should not be less than 70μm. Cement lining conforms to ISO4179 with thickness listed as follows:

Standard Lining and Coating of Ductile Iron Pipe Self Anchor Type

Internal Lining:

Standard Coating: Blast furnace cement mortar

Reinforced Protections: High alumina cement mortar

Special Coatings: Please consult us

External Coating:

Standard Coating: Metallic zinc & Bituminous paint

Reinforced Protections: Polyethylene sleeve applied

Special Coatings: Polyurethane or polyethylene coatings

Other types of coating or lining may be applied upon request.

Packing & Delivery of Ductile Iron Pipe Self Anchor Type

DN80-DN300: Usually by bundles and containers;

DN400-DN2600: Usually by bulk.

During the transportation, the pipes are fixed by timbers, blocks, nails & steel ropes, with cushion at the side in possible moving directions.

Bulk or containers for shipments, and trucks or trains for inland transport.

Shows of Special Lining and Coatings of Ductile Iron Pipe Self Anchor Type

If you have other question, please feel free to consult us.

- Q: Are ductile iron pipes resistant to impact damage?

- Yes, ductile iron pipes are highly resistant to impact damage due to their inherent strength and durability.

- Q: How are ductile iron pipes protected against abrasion or wear?

- Various methods and protective coatings are utilized to protect ductile iron pipes against abrasion or wear. One commonly employed method involves the application of cement mortar lining on the inner surface of the pipe. This creates a smooth and durable layer that effectively resists the damaging effects of flowing water and other substances passing through the pipe. Furthermore, external protection for ductile iron pipes can be achieved by applying a bituminous or epoxy coating. These coatings act as a barrier, safeguarding against external factors like soil or chemicals that may lead to wear or corrosion. By serving as a protective layer, they prevent direct contact between the iron pipe and the surrounding environment. Moreover, in areas where severe abrasion or wear conditions are prevalent, special linings or coatings can be applied. Polyethylene encasement or polyurethane lining can be utilized to provide enhanced protection against abrasion, especially in regions where the pipe is exposed to high turbulence or abrasive materials. In certain cases, ductile iron pipes can also be reinforced with additional materials such as fiberglass or steel wire to increase their resistance to abrasion or wear. These reinforcements offer an extra layer of protection, strengthening the pipe and reducing the likelihood of damage. Overall, ductile iron pipes are designed with a combination of protective measures to ensure their durability and resistance to abrasion or wear. These measures encompass cement mortar linings, protective coatings, special linings or coatings for severe conditions, and reinforcements. These protective methods play a crucial role in prolonging the lifespan of the pipes and maintaining their functionality even in challenging environments.

- Q: How do ductile iron pipes compare to PVC pipes in terms of strength?

- PVC pipes are generally considered to be less strong than ductile iron pipes. Ductile iron, a type of cast iron, is strengthened and made more flexible through the addition of small amounts of magnesium. This treatment enhances its resistance to cracking and breaking under pressure, making it suitable for various applications including water and wastewater transportation. In contrast, PVC pipes are made from a plastic known as polyvinyl chloride. While PVC pipes are relatively durable, they do not possess the same level of strength as ductile iron pipes. They are more susceptible to cracking and breaking when subjected to high pressure or extreme temperature changes. PVC pipes are commonly utilized in low-pressure systems such as irrigation and drainage. In terms of strength, ductile iron pipes exhibit greater tensile strength and can endure higher internal and external pressures compared to PVC pipes. Additionally, ductile iron pipes have a higher resistance to impacts, reducing the likelihood of damage from external forces like heavy machinery or accidental impacts. However, it is important to consider specific project requirements when choosing between ductile iron and PVC pipes. Factors such as cost, ease of installation, corrosion resistance, and the nature of the fluid being transported should all be taken into account.

- Q: Can ductile iron pipes be used for bridge drainage systems?

- Yes, ductile iron pipes can be used for bridge drainage systems. Ductile iron pipes are known for their strength, durability, and resistance to corrosion, making them suitable for various applications, including bridge drainage systems. They can effectively handle the flow of water and withstand the weight and pressure of vehicles passing over the bridge.

- Q: Can ductile iron pipes be used for underground utilities?

- Underground utilities can indeed utilize ductile iron pipes. Renowned for their robustness, strength, and ability to withstand external pressure, ductile iron pipes prove to be a fitting option for subterranean applications demanding remarkable load-bearing capacity, such as utility installations. Furthermore, these pipes exhibit resistance to corrosion, a crucial attribute for underground environments that subject the pipes to dampness and soil conditions. Moreover, ductile iron pipes surpass alternative materials in terms of service life, thereby reducing the necessity for frequent replacements and maintenance. Consequently, ductile iron pipes find widespread application in underground utilities, encompassing water distribution, sewage systems, and gas pipelines.

- Q: How are ductile iron pipes made?

- Ductile iron pipes are made using a specific manufacturing process known as centrifugal casting. This process involves pouring molten iron into a rotating mold, which is usually made of steel. The centrifugal force created by the rotation of the mold helps in distributing the molten iron evenly, ensuring the final product is of high quality. To begin the manufacturing process, a mixture of scrap iron, steel, and recycled material is melted in a furnace at extremely high temperatures. Once the molten iron reaches the desired temperature and consistency, it is ready to be cast into pipes. The rotating mold is first preheated to prevent the molten iron from cooling too quickly. The preheating process also helps in ensuring a smooth surface finish of the pipes. Next, the molten iron is poured into the rotating mold through a central sprue. As the mold spins, the molten iron is forced against the inner walls of the mold due to centrifugal force. This causes the iron to solidify rapidly, resulting in a dense, strong, and corrosion-resistant pipe. The centrifugal force also helps to remove any impurities or slag from the inner surface of the pipe, further enhancing its quality. Once the casting process is complete, the mold is allowed to cool, and the pipe is removed. The pipes are then subjected to various tests to ensure they meet the required quality standards. These tests may include checking the dimensions, mechanical properties, and surface finish of the pipes. After passing the quality tests, the ductile iron pipes are typically coated with a protective lining to prevent corrosion and extend their lifespan. This lining can be made of cement mortar, epoxy, or polyethylene, depending on the intended application of the pipes. In summary, ductile iron pipes are made through the centrifugal casting process, which involves pouring molten iron into a rotating mold. This process ensures the production of strong, corrosion-resistant pipes with a smooth surface finish.

- Q: How does ductile iron pipe compare to steel pipe in terms of durability?

- Ductile iron pipe and steel pipe possess distinct characteristics, but when it comes to durability, ductile iron pipe holds several advantages over its steel counterpart. To begin with, ductile iron pipe boasts exceptional resistance to corrosion. It incorporates a protective layer of zinc or cement lining that safeguards it against rust and corrosion, enhancing its durability and reducing the likelihood of leaks or failures. Conversely, steel pipe is vulnerable to corrosion, particularly when exposed to moisture or specific chemicals. This susceptibility can lead to structural problems and diminish its overall durability. Furthermore, ductile iron pipe exhibits remarkable impact resistance. It can endure substantial loads and external pressures without cracking or breaking, rendering it suitable for applications in high-traffic areas or situations where the pipe may be subject to accidental impacts. Steel pipe, despite its strength, can be more brittle and prone to fractures under similar circumstances. Moreover, ductile iron pipe boasts a longer service life compared to steel pipe. With proper maintenance, it has been known to endure for over a century, making it a dependable and long-lasting choice for infrastructure projects. Steel pipe, although still durable, may necessitate more frequent inspections and maintenance to ensure its longevity. In conclusion, ductile iron pipe surpasses steel pipe in terms of durability due to its corrosion resistance, impact resistance, and extended service life. Nevertheless, the selection between the two ultimately depends on the specific application, budgetary constraints, and other project requirements.

- Q: Is there any cast iron pipe used in the fire hose?

- I do not know, are generally seamless steel pipe or spiral pipe, straight seam pipe.

- Q: How are ductile iron pipes different from cast iron pipes?

- Ductile iron pipes are different from cast iron pipes in terms of their composition and properties. Ductile iron pipes are made from a type of cast iron that has been treated with magnesium to improve its strength and flexibility. This makes ductile iron pipes more durable, impact-resistant, and less prone to cracking or breaking compared to traditional cast iron pipes. Additionally, ductile iron pipes have a higher tensile strength, allowing them to withstand higher internal and external pressures. In summary, ductile iron pipes are a more modern and advanced version of cast iron pipes, offering improved performance and longevity.

- Q: Are ductile iron pipes resistant to frost heave?

- Yes, ductile iron pipes are generally resistant to frost heave due to their strong and flexible nature.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1989 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | Mid East Europe; Eastern Asia; South Africa; |

| Company Certifications | ISO 9001:2008;ISO2531:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 2000 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ductile Iron Pipe Self Anchor Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Meter m

- Supply Capability:

- 250000 Ton Per Year m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords