Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm PN 10

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

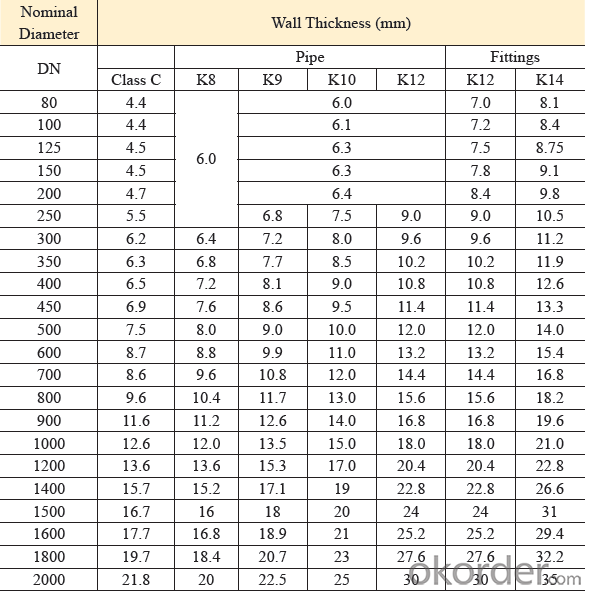

1. size : DN80-DN2000 available with PN16 or PN10 or PN25 flanges

2.Standard : ISO2531/EN545/EN598/AWWA standard

3. WRAS Potable Water FBE Internal Lining

4.Material : Ductile iron

5.Technical: Casting

6. Type: Socket / flange PN10 / PN16 / PN25

7. Length=6m, 5.8m

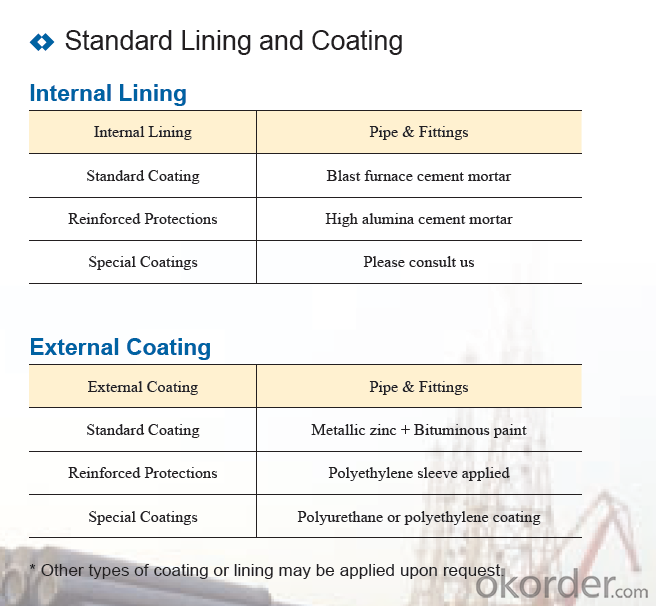

8. Coating: Fusion bonded epoxy to 300 microns Dry Film Thickness

Portland cement lining internally and zinc-rich paint with not less than 70 microns bitumen externally

Quality:

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

Standard Lining and Coating:

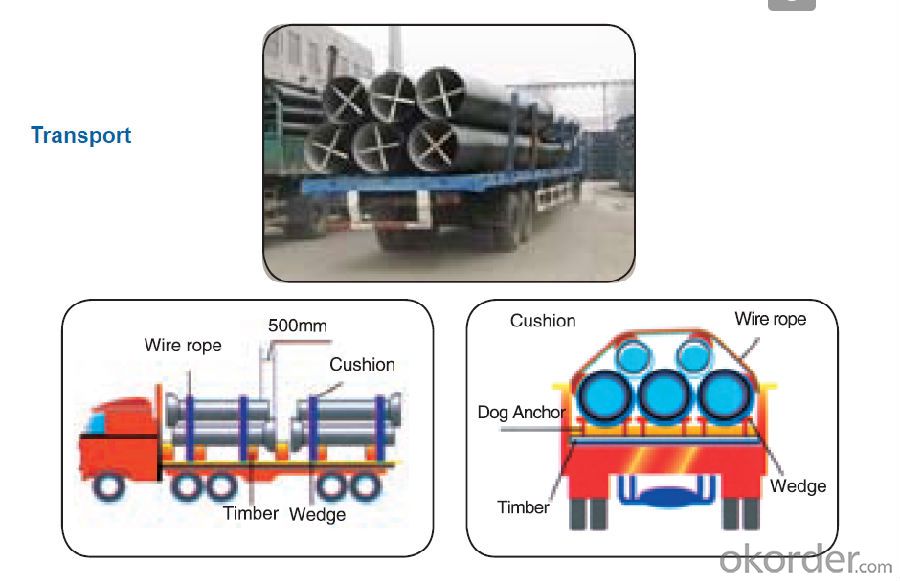

Transport:

- Q: What is the lifespan of ductile iron pipes?

- The lifespan of ductile iron pipes can vary depending on various factors such as the quality of the pipes, the environment they are installed in, and the level of maintenance they receive. However, on average, ductile iron pipes have a lifespan of approximately 80-100 years.

- Q: Are ductile iron pipes suitable for power plant applications?

- Yes, ductile iron pipes are suitable for power plant applications. Ductile iron pipes are known for their high strength and durability, making them capable of withstanding the high-pressure and high-temperature conditions typically found in power plants. Additionally, ductile iron pipes have excellent corrosion resistance, which is crucial in power plant environments where water and chemicals are often present.

- Q: Ductile iron pipes perennial bubbles in the water will rot it

- Ductile iron pipes mainly called centrifugal ductile iron pipe, it has the properties of nature, iron and steel, excellent corrosion resistance, good ductility, good sealing effect, simple installation, mainly for municipal, industrial and mining enterprises, water supply, gas, oil etc..

- Q: What is the expected thermal expansion of ductile iron pipes?

- The expected thermal expansion of ductile iron pipes can vary depending on several factors such as the specific composition of the iron, the temperature range, and the length of the pipe. However, in general, ductile iron pipes have a coefficient of thermal expansion ranging from 10 to 13 microinches per inch per degree Fahrenheit (µin/in/°F). This means that for every one degree Fahrenheit increase in temperature, the ductile iron pipe will expand by approximately 10 to 13 microinches per inch in length. It is important to note that this value is an estimate and may vary slightly depending on the specific conditions and characteristics of the pipe.

- Q: How is ductile iron different from cast iron?

- Ductile iron and cast iron are two types of iron alloys that differ in terms of their composition, properties, and applications. The main difference between ductile iron and cast iron lies in their microstructure and mechanical properties. Ductile iron, also known as nodular cast iron or spheroidal graphite iron, is a type of cast iron that undergoes an additional treatment process to enhance its strength and ductility. This is achieved by adding small amounts of magnesium to the molten iron during the casting process, which results in the formation of graphite nodules throughout the material. These graphite nodules act as stress raisers and prevent the propagation of cracks, making ductile iron more resistant to fractures and providing it with improved ductility compared to cast iron. In contrast, cast iron is a type of iron alloy that contains a higher carbon content than ductile iron. This higher carbon content leads to the formation of graphite flakes within the material, giving cast iron its characteristic brittle nature. Due to its brittleness, cast iron is more prone to cracking and less flexible than ductile iron. However, cast iron has excellent compressive strength and is highly resistant to wear and abrasion, making it suitable for applications where strength and durability are important, such as in engine blocks, pipes, and manhole covers. Another difference between ductile iron and cast iron is their machinability. Ductile iron is generally easier to machine due to its lower carbon content and the presence of graphite nodules, which act as lubricants during the cutting process. On the other hand, the presence of graphite flakes in cast iron can cause tool wear and result in poor surface finish during machining. In summary, ductile iron and cast iron differ in their microstructure, mechanical properties, and applications. Ductile iron offers improved ductility and resistance to fractures, making it suitable for applications requiring flexibility and impact resistance. Cast iron, with its higher carbon content and graphite flakes, provides excellent compressive strength and wear resistance, making it ideal for applications requiring strength and durability.

- Q: Are ductile iron pipes suitable for acidic or alkaline environments?

- Ductile iron pipes are generally suitable for both acidic and alkaline environments, although their performance may vary depending on the specific conditions. Ductile iron is a type of cast iron that has been treated with a small amount of magnesium to enhance its strength and flexibility. This treatment allows ductile iron pipes to withstand a wide range of conditions, including those found in acidic or alkaline environments. In acidic environments, ductile iron pipes provide good resistance to corrosion. The iron in the pipes reacts with the acid to form a protective layer of iron oxide, which helps prevent further corrosion. However, it is important to note that the performance of ductile iron pipes in acidic environments can be influenced by factors such as the concentration of the acid and the temperature. In highly concentrated or extremely acidic conditions, alternative materials like stainless steel or corrosion-resistant alloys may be more suitable. Similarly, in alkaline environments, ductile iron pipes exhibit good resistance to corrosion. The alkaline conditions in these environments typically help to passivate the surface of the iron, forming a protective layer that prevents further corrosion. However, as in acidic environments, the specific conditions and concentrations of alkalis may impact the performance of ductile iron pipes. In cases of very high alkalinity or extreme temperatures, other materials like plastic or concrete pipes may be more appropriate. It is worth noting that although ductile iron pipes are generally suitable for both acidic and alkaline environments, regular maintenance and monitoring are crucial to ensure their long-term performance. Proper attention should be given to monitoring the pH levels and other chemical characteristics of the environment to identify any potential issues or required maintenance. Consulting with experts or engineers in the field can provide valuable insights and guidance in selecting the most appropriate materials for specific acidic or alkaline environments.

- Q: How does ductile iron pipe handle changes in pipe diameter or size?

- Ductile iron pipe offers a convenient solution for dealing with alterations in pipe diameter or size. Its excellent flexibility and capacity to adapt to changes in pipe dimensions without compromising its structural integrity are a result of its unique composition, which contains a significant amount of graphite nodules that provide ductility and elasticity to the material. When faced with adjustments in pipe diameter or size, ductile iron pipe can be easily manufactured or modified to meet specific requirements. It can be cast or fabricated in different diameters and lengths, allowing for seamless integration and adaptability within a pipeline system. This versatility proves particularly advantageous when connecting different pipe sizes or making alterations to the pipeline layout. Furthermore, the superior mechanical properties of ductile iron pipe enable it to withstand the stresses and forces associated with changes in pipe diameter or size. It possesses high tensile strength, impact resistance, and durability, ensuring its ability to handle the internal and external pressures exerted on the pipe during operations. Moreover, the jointing systems employed with ductile iron pipe contribute to its ability to handle changes in diameter or size. Various joint types, including push-on, restrained, or mechanical joints, provide secure and leak-free connections between different pipe sections. These joints facilitate easy assembly and disassembly, enabling efficient adjustments to the pipe diameter or size as required. In conclusion, ductile iron pipe is well-equipped to handle changes in pipe diameter or size due to its inherent flexibility, adaptability, and robustness. Its composition, manufacturing capabilities, and jointing systems all contribute to its capacity to accommodate variations in pipe dimensions without compromising its performance.

- Q: What is the difference between ductile iron and cast iron pipes?

- The main difference between ductile iron and cast iron pipes lies in their composition and properties. Ductile iron pipes are made from an alloy of iron, carbon, and silicon, which makes them more flexible and resistant to cracking. On the other hand, cast iron pipes are made from a mixture of iron, carbon, and other elements, which provides them with a higher resistance to corrosion and pressure. In summary, ductile iron pipes are more flexible and durable, while cast iron pipes are more resistant to corrosion and pressure.

- Q: Will the quality of ductile iron shrink?

- This is a ductile iron is prone to problems, manhole covers, large flat pieces, you have to see clearly, and some appear to be concave, not shrink, it may be caused by large gas emissions, not out

- Q: How does ductile iron pipe perform in extreme weather conditions?

- Ductile iron pipe performs exceptionally well in extreme weather conditions. Its superior strength and durability make it resistant to cracking, breaking, or corroding, even in harsh environments. This stability allows it to withstand extreme temperatures, high winds, heavy rain, and even seismic activities, ensuring reliable performance and longevity.

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm PN 10

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords