Duct Iron Pipe DI Pipe ISO 2531 DN 80-300mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

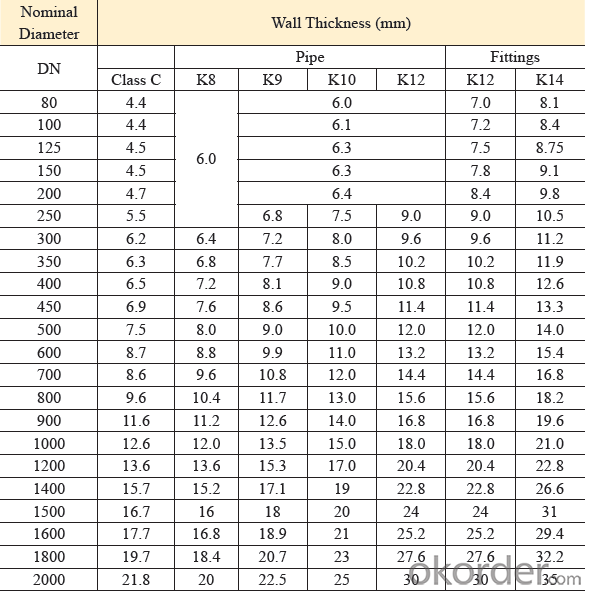

1. size : DN80-DN2000 available with PN16 or PN10 or PN25 flanges

2.Standard : ISO2531/EN545/EN598/AWWA standard

3. WRAS Potable Water FBE Internal Lining

4.Material : Ductile iron

5.Technical: Casting

6. Type: Socket / flange PN10 / PN16 / PN25

7. Length=6m, 5.8m

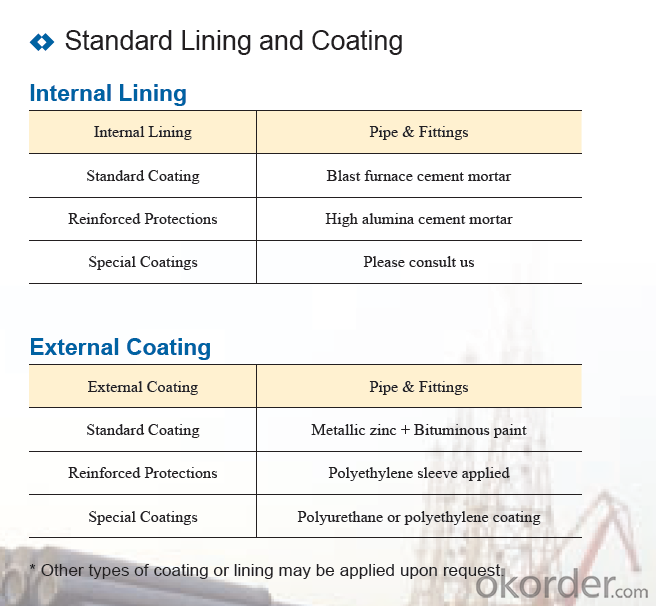

8. Coating: Fusion bonded epoxy to 300 microns Dry Film Thickness

Portland cement lining internally and zinc-rich paint with not less than 70 microns bitumen externally

Quality:

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

Standard Lining and Coating:

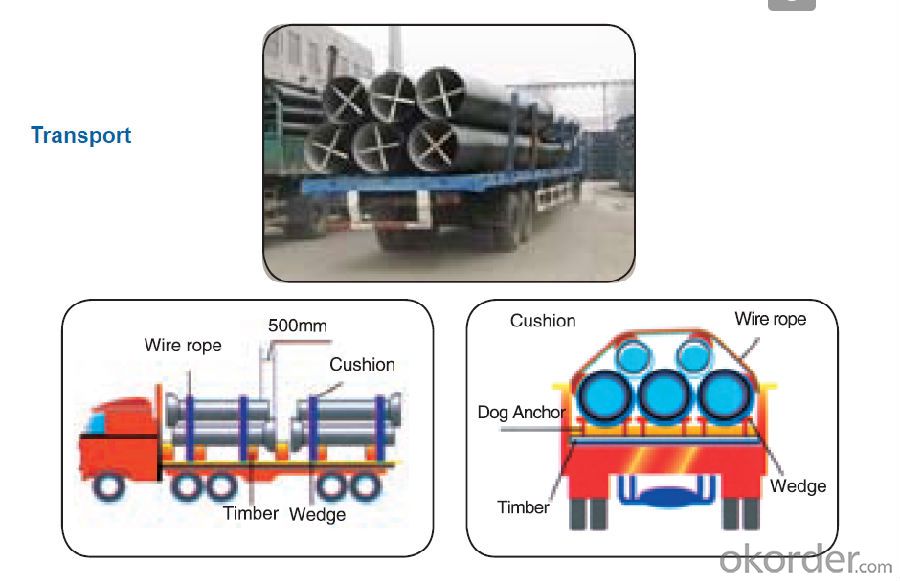

Transport:

- Q: How can the internal and external walls of ductile iron pipes be protected from corrosion?

- Internal walls can be painted anti-corrosion paint, exterior anti-corrosion can choose to paint, but also useful anti-corrosion tape, or do 3PE anti-corrosion, look at your anti-corrosion requirements, cost budget and other construction objective conditions.

- Q: Can ductile iron pipes be used for irrigation of sports fields?

- Yes, ductile iron pipes can be used for irrigation of sports fields. Ductile iron pipes are known for their strength, durability, and flexibility, making them an ideal choice for various applications, including irrigation. These pipes have high resistance to external pressures and impact, which is beneficial for sports fields that may experience heavy foot traffic and potential damage. Additionally, ductile iron pipes have excellent corrosion resistance, ensuring long-term performance and minimal maintenance. Their smooth interior surface also allows for efficient water flow, preventing clogs and ensuring adequate irrigation for the sports fields. Overall, ductile iron pipes are a reliable and suitable option for irrigation systems in sports fields.

- Q: How do ductile iron pipes handle ground movement or settlement?

- Ductile iron pipes are renowned for their remarkable strength and flexibility, enabling them to effectively manage ground movement or settlement. Ground movement or settlement pertains to the natural shifts or settling of the earth's surface, which can exert stress on subterranean infrastructure such as pipes. Concerning ground movement, ductile iron pipes possess the advantage of enduring and absorbing the pressure and movement caused by shifting soil. The material's ductility permits the pipes to flex and bend to a certain extent without fracturing. This flexibility aids in distributing the load and minimizing the potential for harm. Additionally, ductile iron pipes exhibit high resistance to cracking or fracturing, even under extreme circumstances. This resilience stems from the material's unique microstructure, which imparts excellent tensile strength and impact resistance. Consequently, ductile iron pipes can withstand external forces and ground settlement without compromising their integrity. To further augment their capacity to handle ground movement or settlement, ductile iron pipes are frequently installed using flexible joints. These joints allow for slight movement and accommodate any shifting or settling of the ground. Furthermore, proper bedding and backfilling techniques are employed during installation to provide added support and stability. Overall, ductile iron pipes possess a proven track record in managing ground movement or settlement. Their strength, flexibility, and resistance to cracking establish them as a dependable choice for subterranean infrastructure, ensuring the durability and efficiency of water distribution systems.

- Q: What is the maximum temperature that ductile iron pipe can handle?

- The maximum temperature that ductile iron pipe can handle typically ranges between 350-400 degrees Fahrenheit.

- Q: What is the expected surge pressure rating of ductile iron pipes?

- The surge pressure rating for ductile iron pipes can vary based on several factors, including pipe diameter, thickness, joint type, and manufacturer specifications. Generally, ductile iron pipes are built to withstand surge pressures ranging from 150% to 200% of their working pressure rating. For instance, if a ductile iron pipe has a working pressure rating of 250 psi, it can typically handle surge pressures of 375 psi to 500 psi. To obtain accurate surge pressure ratings for the specific ductile iron pipes being used, it is crucial to refer to the manufacturer's specifications and guidelines.

- Q: What is the expected maintenance for ductile iron pipes?

- The expected maintenance for ductile iron pipes typically includes regular inspections for signs of corrosion or damage, cleaning to remove any sediment or debris buildup, and occasional repair or replacement of sections that are worn or compromised.

- Q: Are ductile iron pipes suitable for use in food processing plants?

- Ductile iron pipes are indeed suitable for use in food processing plants due to their numerous advantageous qualities. Firstly, they possess immense strength and durability, enabling them to withstand high-pressure situations. This feature proves crucial in food processing plants where pipes encounter diverse pressures during liquid and slurry transportation. Moreover, ductile iron pipes exhibit exceptional resistance to corrosion. This attribute becomes paramount in food processing plants as the pipes come into contact with various types of food, beverages, and cleaning agents, which can gradually corrode them. The corrosion resistance of ductile iron pipes ensures the pipes' integrity and safeguards the food products from contamination. Furthermore, these pipes display remarkable resistance to temperature fluctuations, rendering them suitable for the extreme temperature conditions often present in food processing plants. They can endure both hot and cold fluids without compromising their structural integrity. Additionally, ductile iron pipes possess a smooth inner surface, contributing to the maintenance of food product quality and purity. The smooth interior minimizes deposits like scaling or biofilm, thereby reducing the risk of bacterial growth. This quality proves essential in food processing plants where maintaining a hygienic environment is of utmost importance. Lastly, ductile iron pipes are easy to install and maintain. They boast a lengthy service life and require minimal upkeep, thereby minimizing downtime and associated costs in food processing plants. Considering these factors, ductile iron pipes emerge as a reliable and suitable choice for use in food processing plants. They ensure the safe and efficient transportation of fluids while meeting the industry's stringent hygiene and quality requirements.

- Q: Ductile iron pipe, socket connection, pipe length, you can cut open it?

- Yes, but the pipe that needs cutting is a cut off pipe with a scissors mark.

- Q: Are ductile iron pipes resistant to frost heave?

- Yes, ductile iron pipes are generally resistant to frost heave due to their strong and flexible nature.

- Q: Classification of cast iron pipes

- Continuous cast iron straight pipe:Continuous cast iron pipe, namely continuous casting gray cast iron pipe, suitable for water and gas pressure fluid delivery.

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 80-300mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords