Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm PN 40

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

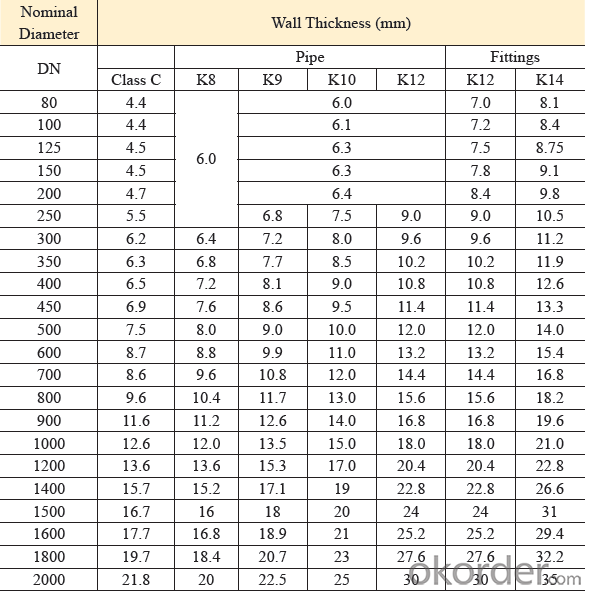

Specification:

1. size : DN80-DN2000 available with PN16 or PN10 or PN25 flanges

2.Standard : ISO2531/EN545/EN598/AWWA standard

3. WRAS Potable Water FBE Internal Lining

4.Material : Ductile iron

5.Technical: Casting

6. Type: Socket / flange PN10 / PN16 / PN25

7. Length=6m, 5.8m

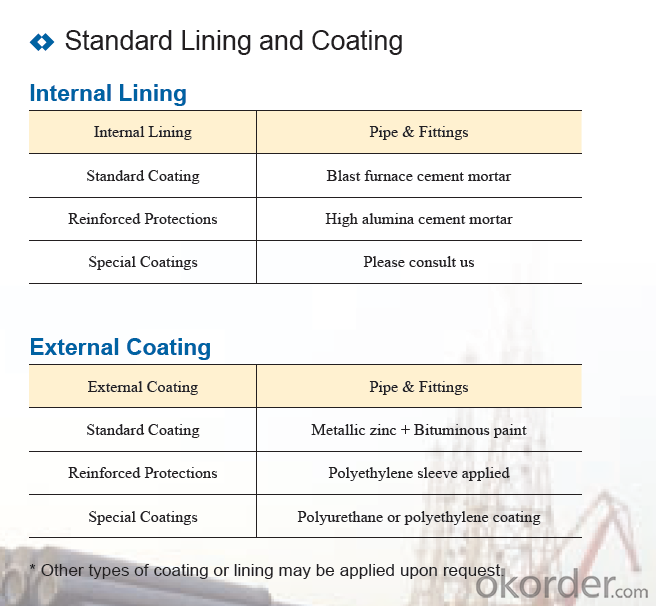

8. Coating: Fusion bonded epoxy to 300 microns Dry Film Thickness

Portland cement lining internally and zinc-rich paint with not less than 70 microns bitumen externally

Quality:

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

Standard Lining and Coating:

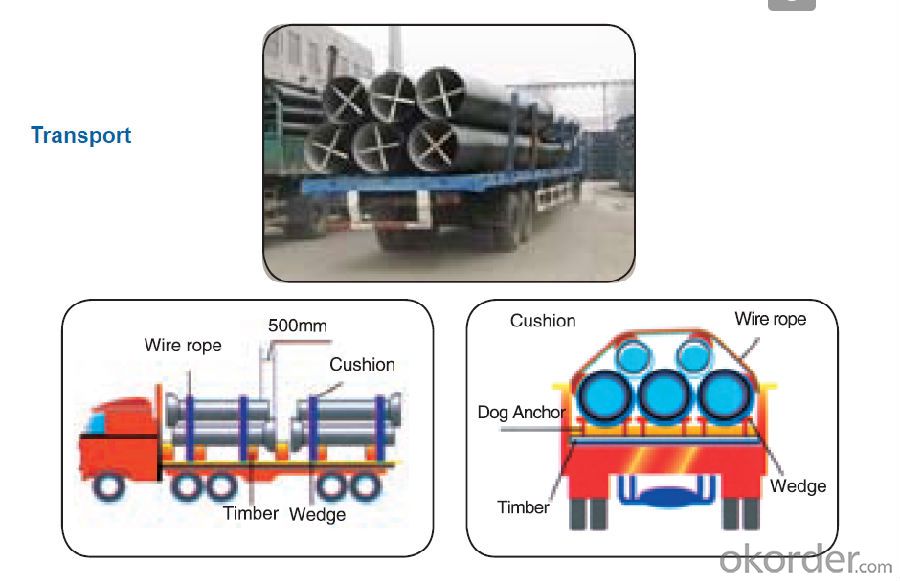

Transport:

- Q: Are ductile iron pipes resistant to acid attacks?

- Yes, ductile iron pipes are generally resistant to acid attacks. Ductile iron has a protective layer of graphite and a dense matrix structure that helps in preventing the penetration of acid. However, prolonged exposure to highly corrosive acids or extreme pH levels may still cause some degradation over time.

- Q: Can ductile iron pipe be used for geothermal heat exchange systems?

- Yes, ductile iron pipe can be used for geothermal heat exchange systems. Ductile iron pipe is known for its strength and durability, making it suitable for underground applications such as geothermal heat exchange systems. Additionally, it has good corrosion resistance and can withstand high temperatures, which are important factors in geothermal systems.

- Q: Can ductile iron pipes be used for stormwater drainage?

- Yes, ductile iron pipes can be used for stormwater drainage. Ductile iron pipes are known for their strength, durability, and ability to withstand heavy loads, making them a suitable choice for various applications, including stormwater drainage systems.

- Q: What is the ductile cast iron pipe

- Have not heard of the nodular cast iron pipe pipe, ductile iron may be a tube or a certain short tube is referred to as excellent grade.

- Q: Are ductile iron pipes resistant to corrosion?

- Ductile iron pipes possess resistance against corrosion, indeed. Ductile iron, a variant of cast iron, undergoes treatment with additional substances to enhance its flexibility and durability. These substances, like graphite, magnesium, and cerium, form a protective barrier on the pipe's surface, rendering it highly resistant to corrosion. Furthermore, ductile iron pipes are frequently coated with either cement mortar or a fusion-bonded epoxy coating, thereby augmenting their resistance against corrosion. This attribute renders ductile iron pipes suitable for a range of applications, including water distribution, wastewater treatment, and industrial pipelines, where corrosion is commonly encountered.

- Q: How can the cast iron pipe be connected?

- Cast iron pipes are flanged and socket connected

- Q: Are ductile iron pipes suitable for use in agricultural applications?

- Yes, ductile iron pipes are suitable for use in agricultural applications. Ductile iron pipes are known for their high strength and durability, making them ideal for withstanding the heavy loads and pressures often found in agricultural operations. Additionally, they have excellent corrosion resistance, which is important in agricultural environments where pipes may be exposed to chemicals or fertilizers. Ductile iron pipes also have a long lifespan, reducing the need for frequent replacements and minimizing maintenance costs. Overall, their robust nature and ability to handle various agricultural demands make them a reliable choice for use in agricultural applications.

- Q: What is the average cost of ductile iron pipe?

- The cost of ductile iron pipe can vary depending on various factors, including the pipe's diameter, length, thickness, supplier, and location. Generally, the price range for ductile iron pipe is around $40 to $200 per linear foot. However, it is crucial to understand that these figures are estimations and may change due to market conditions and other variables. To obtain precise pricing information that aligns with your project needs, it is advisable to reach out to local suppliers or distributors.

- Q: How do ductile iron pipes handle ground settlement due to construction activities?

- Ductile iron pipes have the ability to handle ground settlement caused by construction activities due to their flexibility and strength. These pipes are designed to withstand external pressure and can accommodate minor ground movements without significant damage or failure. The ductility of the material allows the pipes to deform slightly, absorbing the ground settlement and preventing them from cracking or breaking. Additionally, the joints in ductile iron pipes are typically flexible, allowing for further movement and reducing the risk of leakage or structural issues. Overall, ductile iron pipes are well-suited for withstanding ground settlement and ensuring the integrity of the pipeline system during construction activities.

- Q: The plug connection DN800 ductile iron pipe has been installed. "Shall I think so?"

- In many areas of our country, ductile iron pipe in the middle and small diameter to tube connected with the tube, the bearing type or flange interface method; ductile iron, angle limit must be allowed better seismic performance and sealing performance.

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm PN 40

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords