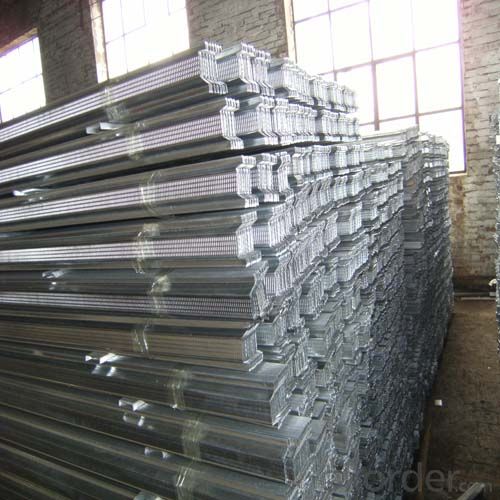

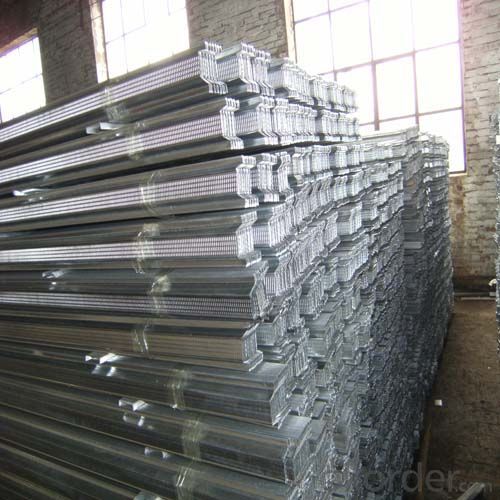

Drywall System Stainless Galvanized Steel Profile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Drywall Metal Profile

Drywall ceiling Channel is galvanized metal structure used in non-bearing partition systerm .

Drywall steel frame system is a popular way to be used to divide the space,especially using in commercial buildings.

HUILON Drywall Steel Frame System is made of galvanized steel sheet with good rust-Proof function.A variety of frames are ready for customers' demands and designers' choice for different purposes and places. One of our merits is the special hole for channel on C-stud in per 6Ocm which is easy for workers to install the electric lines and water tubes.CH and IH type of studs are the special type we developed to solve the hard work situation in elevator ventilator and offer a better protection of workers' safety.

Our dry wall steel frames are covered with HUILON magnesium fireproof boards and fulfilled with material which is heat insulation and noise-proof mineral wool between two layers of boards. It will create a better living environment than the traditional building materials.

Suspension ceiling structure,Galvanized metal structure which is the vertical metal framework used in non-bearing partition system.

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Light steel keel gypsum board wall height is how to determine

- D = <l 240 Parameter Description: d: Maximum deformation of the component under uniform load, unit mmq: Uniform load, unit Pa, test In the composition of the material, the cross-sectional nature of the wall stiffness coefficient: EI value of the test to determine the length of the wall The use of 15mm plate instead of 12.5mm plate, the wall stiffness EI can be increased by 33% 2. The keel spacing from 600mm to 400mm, wall EI value increased by 50% 3. The keel spacing reduced from 400mm to 300mm, the wall EI value increased by 50% 4. keel on the wall than the non-buckle wall, EI value increased by 60% 5. Use type I keel than the use of C-keel, EI value increased by at least 100%. The effect of thickness on the EI value is very small relative to several other factors, EI is called bending stiffness, 75 keel spacing is 400, double-sided single layer 12mm gypsum board wall EI = 4.6 × 1010 according to the actual test EI value of the structural partition system: (unit: N.mm2, 1010)

- Q: Light steel keel wall Why use gypsum board to do grass-roots level?

- Longgang wall: light steel keel is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, Easy to deformation and so on.

- Q: Lightproof wall how to fire

- These three criteria are three basic requirements for detecting whether a partition can reach a certain refractory limit; Landlord asked if the fire? Very simple to say that fire is built on the basis of thermal insulation to achieve the purpose of fire;

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- Mainly to see the use of the environment, if used in a humid environment, the life must be short, so the bathroom wall is best not to use light steel keel search.

- Q: PVC plastic buckle the corners of the corner is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall surface and ceiling how fixed

- Plastic buckle the corners of the line, the normal practice for the eye plug plug stopper, with self-tapping screws fixed. Plastic buckle has its own slot, in the male slot with self-tapping screws fixed on the keel. Light steel keel gypsum board wall, with the heaven and earth keel to the ground in the ground punching cork with nails fixed; Tianlong the same.

- Q: How to install light steel keel gypsum board wall

- Light steel keel gypsum board installation should generally be through the following steps: wall line → wall construction → installation along the ground, along the top keel → installation of vertical keel → fixed door and window makeup → installation of the wall side of the gypsum board → install another side of the plaster price → seam processing → wall decoration. 1. Wall line According to the design of the wall, in the ground to release the wall bit line, and the line leads to the ceiling and side walls. 2. Wall construction First on the wall and floor, ground contact parts for cleaning, coated with interface treatment agent together, then pouring C20 concrete wall, the wall surface should be smooth, both sides should be vertical. 3. Install the edge along the top keel Along the ground, along the top keel in place, with the nail fixed, shot nail from the 900mm, the location of the nail should avoid the laying of the tube area. 4. Install the vertical keel According to the determined vertical keel spacing, along the ground, along the top keel on the line drawing line. The vertical keel is arranged by the end of the wall. When the doors and windows are provided with windows and doors, they should be arranged from one side or both sides of the door window. When the last keel from the wall of the size is greater than the provisions of the keel spacing, you must add a keel. The upper and lower ends of the keel should be fixed along with the top, along the keel with rivets or tapping screws.

- Q: I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- These two estimates are problematic, you can use light steel keel cement pressure plate nail steel wire mesh paint, do waterproof post-paste wall tiles, the following also do waterstops

- Q: Light steel keel wall gypsum board seams how to deal with? Including smallpox

- First with gypsum slit smooth, and then paste the old white leather paste with kraft paper, as long as the joints have to deal with. Better than the kind of gauze belt. My family used

- Q: Light steel keel gypsum board partition wall brush black latex paint, I would like to change the brush blue latex paint, how to deal with grassroots?

- Can ah, the paper gypsum board above also scraping putty ah, the workers will deal with, you just ask the request on it, professional things professional do

- Q: What is the pros and cons of a brick or a gypsum board?

- Brick, then the shortcomings are obvious: take up space, the construction is very troublesome, brick weight caused by the future you think it is not good demolition demolition is not good, is it And brick sound insulation is completely unprofessional, the general people also use hollow brick, hollow brick sound insulation effect? Oh, presumably contact people are clear that you do not think it is not sound on the good.

Send your message to us

Drywall System Stainless Galvanized Steel Profile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords