Ceiling Profile for Partition Decoration Stud and Track

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Characters

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

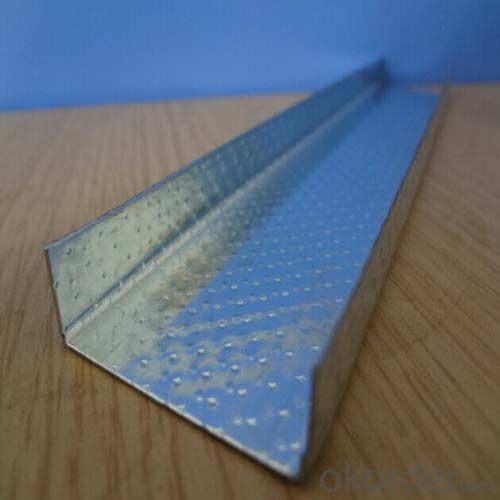

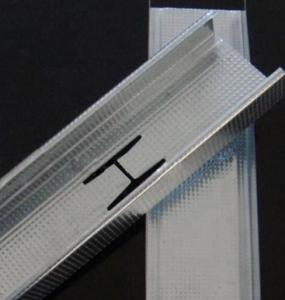

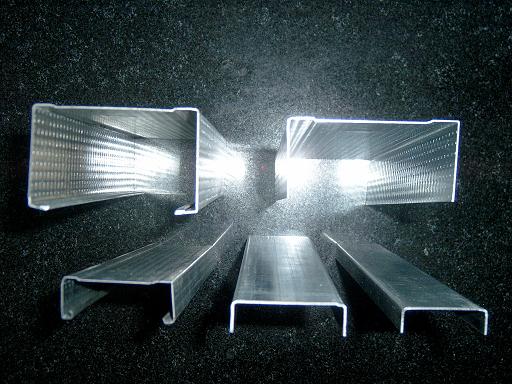

Drywall partition Hot dipped zinc galvanized stee strip zinc coating is 40-180g/m2.good quality and competitive price

Item Name:furring channel

Size: 68*35*22mm

Thickness:0.4-0.8mm

furring channel Surface:Zinc Galvanized

Specifications

Item name: furring channel

furring channel Thickness:0.4-0.8mm

Surface:Zinc Galvanized

Furrring channel Packing: Clear tape, 20pcs/bundle

Furring channel Technicology

adopting high-grade quality hot-dipped galvanized steel,The products surface zero spangle,and intensity toughness, besides, it can add 20% more than common.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures

- Q: Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- Construction Measures of Caustic Sintered Calcium Silicate Board Ceiling 1, the roof height level: according to the level of the floor level, with the vertical bar to the ceiling design elevation, along the wall to the surrounding height of the ceiling. 2, designated keel file line: according to the design requirements of the primary and secondary keel spacing arrangement, has been on the roof of the standard elevation of the keel sub-line. 3, the installation of the main keel boom, playing a good ceiling elevation and keel sub-file position, to determine the boom under the head of the elevation, according to the main keel location and hanging spacing, the end of the bucket without screw button embedded with the floor expansion Bolt connection is fixed. 4, install the main keel 1> equipped with boom pheasant 2> Install the pendant on the main keel 3> Install the main keel: the main keel will be assembled hanging pendant, according to the location of the sub-line to hang the hanging pieces into the corresponding ring bolt. 4> main keel connected with the installation of connectors, pull the line to adjust the elevation, from the arch and straight. 5> around the keel with nailing Hong set. Design no request, the nail spacing of 1000mm.

- Q: Light steel keel ceiling do anti-support angle iron how fixed on the main keel, how fixed on the ceiling surface?

- When installing the support material, use the angle iron to drill the hole first in the angle iron, and then use the wire to the angle iron can be tied to the hanging bar, do not need to fix it on the ceiling, the length of the support material, generally to support Of the ends of the hanging ends of not less than 20 cm can be. For example, if the length of the hanging bar is 2 meters, then the length of the support should not be less than 1.60 meters on the two ends of the average points on the line.

- Q: 140 square meters light steel keel double gypsum board ceiling fee, material costs about how much money

- The general cost of about 4,000 materials, first-line brand of materials costs around 7000, labor costs about 3000-4500 between ...

- Q: How to pick the ceiling keel

- The keel is an indispensable part of the decoration ceiling, which includes wood keel and light steel keel. Use wood keel to pay attention to the wood must be dry. Now most of the home decoration is not easy to deformation, with fire performance of light steel keel, selection should pay attention to the thickness of the keel, preferably not less than 0.6 mm ceiling metal keel is generally made of light steel and aluminum alloy, with light weight , Rigidity, fire and seismic performance is good, easy to install and so on, according to profile section points, there are U-keel and T-keel.

- Q: Ecological wood veneer gypsum board closed light steel keel ceiling decoration drawings so what is the meaning? How to understand

- The above is just speculation in accordance with the practice only, the designer belongs to the garbage family, did not see such a "note". It is recommended to consult the designer, be confirmed, so as to avoid mistakes.

- Q: Light steel keel ceiling ,,, Commonly used is 50 to 50 system ,,, Light steel keel, the surface after the heat crossing zinc treatment, and long no rust, no deformation ,,, State regulations installed on the light steel keel on the gypsum board, as a class A fireproof material Wood keel because the water is too large, and love deformation ,,, no fire, so you can see Large place, no one is covered with wooden keel. The There are two real problems: 1 "with wood keel, the effect is not bad, and the cost is not cheap ,,, now light steel 50 keel and 3 * 5 wooden cost

- Landlord or light steel bar! One word: province.

- Q: Light steel keel moisture-proof gypsum board ceiling which is the grass-roots which is the surface layer?

- Nice, smooth, neat positive

- Q: Wood keel and light steel keel were used for where?

- Light steel keel main use in a large area of the ceiling, the general home decoration in addition to kitchen and steel is used outside the light keel are used wood keel. Be sure to pay attention to full brush fire retardant coating.

- Q: Home decoration living room ceiling (light steel keel or wood keel) between the two, what is the difference?

- Family wood keel more convenient, light steel keel is mainly used in large space ceiling -

- Q: Light steel keel ceiling boom and whether the strong electric lines can be common

- It is best not to put together. Because light steel keel rods are metal substances, there is a strong ability to conduct. If you wear a wire tube can share a pole.

Send your message to us

Ceiling Profile for Partition Decoration Stud and Track

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords