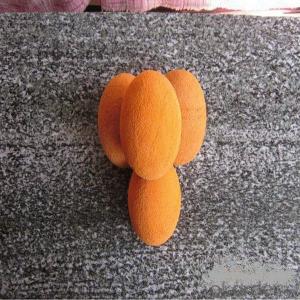

DN125 Concrete Pump Pipeline Rubber Cleaning Ball

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Pump Pipe Cleaning Ball

SIZE

Cleaning Ball --- DN80, DN100, DN125, DN150

Cleaning Column --- DN125, DN150

STYLE

Cleaning Ball --- hard type, soft type

Cleaning Column --- hard type

FUNCTION

Its main function is used for cleaning concrete pipeline.

PACKING

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Feature

1. It is mainly used for cleaning all kinds of diameter of pump pipe cleaning tool,

maintenance of pipeline cleaning, made channel is more unblocked, unimpeded.

2. Greatly improving the work efficiency.

3. Prolong the service life of the various diameter pipe .

The main products

1. Concrete pump pipe :ST52 concrete pump pipe , 45Mn2 Wear resistant pipes, Twin wall pipes ,Reducer , tee, .ect.

2. the towed concrete pump, Concrete placing boom series.

3. Concrete pump truck fittings : Wear plate and wearring, Svalves, Concrete pump piston , delivery cylinder,.ect

4. Concrete pump clamp : DN80, DN100,DN125,DN150 Casting pipe clamp and Forged clamp.

5. Other accessories: Rubber hose , Cleaning ball , Sponge plug, Seal, The bearing seat, Flange etc.

- Q: What does the rubber tire do to people?

- Rubber is an elastic polymer. Rubber can be obtained from the plant sap, can also be man-made, both have many applications and products, such as tires, washers, etc., has become an important economic crop. The cultivation of rubber is mainly concentrated in Southeast Asia, such as Thailand, Malaysia and Indonesia.

- Q: Are rubber products poisonous? What harm?

- A product of a combination of many components, produced by certain cross reactions, with high elasticity. In general by the rubber, filler, plasticizer, active agent, accelerator, curing agent and other additives (pigment, odor, conductive composition etc.).

- Q: Is mixed silicone rubber dangerous?

- With excellent thermal stability, high and low temperature resistance, can -60 to +250 DEG C under the condition of long-term work, ozone resistance, weatherability and good electrical properties, corona resistance, electric arc, electric spark is extremely strong, with chemical stability, weathering resistance, radiation resistance, physical inertia and good air permeability.

- Q: What is the difference between vulcanized rubber and butyl rubber?

- Vulcanized rubber refers to vulcanized rubber, has the characteristics of constant viscosity, not easy to break, and rubber products are mostly made of this kind of rubber. Also known as "mature rubber", commonly known as rubber or rubber.

- Q: Explain why butyl rubber is more resistant to oxidation and aging than other elastomers, such as natural rubber

- Usually smoked rubber, crepe, dry glue, glue... Etc.. The dry glue without smoke and natural rubber, color to dry shallow, suitable for light and color products

- Q: How is rubber made? What kind of equipment do you need? How much is it?

- Machining process:This process involves basic processes such as plasticization, mixing, calendering or extrusion, forming and vulcanizing. Each process has different requirements for the product and cooperates with a number of auxiliary operations. In order to make all the necessary coordination agent in rubber, rubber Plasticating must first go through improving the plastic; then by mixing carbon black and all kinds of rubber and rubber additives are evenly mixed into rubber; rubber shaped blank after extruding; and then the textile materials and rolled hanging glue or glue (or metal material) together formed into semi-finished products; finally after vulcanization will have final semi-finished products made of high elastic plastic. The products with higher precision requirements, such as oil seals, O rings and seals, also need trimming and deburring, and manual trimming, mechanical trimming and cold trimming can be used.

- Q: What is a rubber accelerator? What role?

- Thiofide ETU (Na-22), Thiofide DETU, Thiofide ZDC (EZ), Thiofide ZDMC (PZ) Thiofide ZDBC (BZ), Thiofide ZMBT (MZ), Thiofide TMTM, Thiofide MBT (M), Thiofide MBTS (DM)

- Q: Why does rubber stink?

- After vulcanization, the chemical composition of the rubber is sulfur compounds and smells bad.

- Q: What do you pay attention to when using rubber?

- Note the aging of rubber rubber rubber and its products in the processing, storage and use of the process, due to the comprehensive effect of internal and external factors caused by the physical and chemical properties and mechanical properties of rubber gradually deteriorated, and finally lose value, this kind of change is called aging of rubber. The surface is characterized by crazing, sticking, hardening, softening, powdering, discoloration, mildew, etc..

- Q: What kind of rubber is suitable for waterproof aprons?

- Typical properties of rubber material are low glass transition temperature and high elasticity. The main properties of common rubber materials are shown in the schedule after the teaching materials.

Send your message to us

DN125 Concrete Pump Pipeline Rubber Cleaning Ball

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords