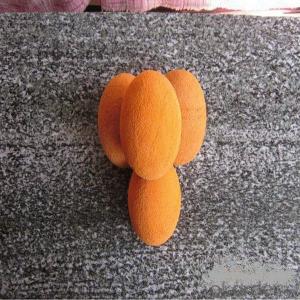

DN125 Concrete Pump Pipeline Cleaning Ball

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Pump Pipe Cleaning Ball

SIZE

Cleaning Ball --- DN80, DN100, DN125, DN150

Cleaning Column --- DN125, DN150

STYLE

Cleaning Ball --- hard type, soft type

Cleaning Column --- hard type

FUNCTION

Its main function is used for cleaning concrete pipeline.

PACKING

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Feature

1. It is mainly used for cleaning all kinds of diameter of pump pipe cleaning tool,

maintenance of pipeline cleaning, made channel is more unblocked, unimpeded.

2. Greatly improving the work efficiency.

3. Prolong the service life of the various diameter pipe .

The main products

1. Concrete pump pipe :ST52 concrete pump pipe , 45Mn2 Wear resistant pipes, Twin wall pipes ,Reducer , tee, .ect.

2. the towed concrete pump, Concrete placing boom series.

3. Concrete pump truck fittings : Wear plate and wearring, Svalves, Concrete pump piston , delivery cylinder,.ect

4. Concrete pump clamp : DN80, DN100,DN125,DN150 Casting pipe clamp and Forged clamp.

5. Other accessories: Rubber hose , Cleaning ball , Sponge plug, Seal, The bearing seat, Flange etc.

- Q: Which is better waterproof performance, neoprene or silica gel?

- Chloroprene rubber and chloroprene rubber, chloroprene rubber is Xinping (i.e. 2-, -1,3- chloride butadiene) as the main raw material for the polymerization of alpha elastomer. Neoprene should be stored in a cool, ventilated, dry warehouse. Do not stress it to prevent it from being laid. It is widely used in weather resistant products, viscose soles, paints and rocket fuels.

- Q: What are the differences in the properties of neoprene models?

- Different types of applications are different:CR122 chloroprene rubber: belt, conveyor belt, wire and cable, oil resistant rubber sheet, oil hose, sealing materials and other rubber products.CR232 chloroprene rubber: cable sheath, oil resistant hose, rubber seals, adhesives and so on.CR2441 2442 chloroprene: a raw material used in adhesives for bonding metals, wood, rubber, leather and other materials.CR321 322 type chloroprene rubber cables, plywood, ordinary and hose, oil resistant rubber boots, air duct, cloth, tent cloth, conveyor belt, conveyor belt, rubber seals, agricultural capsule cushion, lifeboat etc..Used as toughening agent for modified acrylate fast structural adhesive (SGA).

- Q: Does antirust oil affect rubber?

- Antirust oil on rubber must have some influence, and a variety of anti rust oil, you can choose corrosive minimum rust preventive oil,,

- Q: How does the rubber part of the watch become yellow?

- It is mainly divided into two kinds of natural rubber and synthetic rubber. Natural rubber is made from rubber, rubber and grass. Synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life. It has a wide range of uses. [1] can also be divided into rubber with natural rubber, general rubber, styrene butadiene rubber, nitrile rubber, silicone rubber, butadiene rubber, butyl rubber, EPDM rubber, chloroprene rubber types.

- Q: Aging of rubber parts for automobiles

- The engine bracket, the foot pad, the leaf spring bushing, and the shock absorbing foot cushion, such as rubber aging, will vibrate abnormally and cause abnormal noise, which will cause the damage of the whole component and even the radiation to the surrounding parts. In addition, the rubber bushings on the trucks need to be replaced, it is not an easy task and sometimes requires larger actions. For example, the shock absorber rubber of the cab needs to be lifted if it needs to be replaced.

- Q: UV glue can glue rubber products?

- If only the outside screen is glued, the UV glue with a surface fixing type is OK (if the crack is too big and the glue can seep in, it is not recommended to mend), but the crack can still be seen.

- Q: Is the odour emitted by industrial rubber poisonous?

- Rubber production process including plastic, mixing, rolling or extrusion, molding and vulcanizing and other basic processes, each process for the products have different requirements, respectively, with a number of auxiliary operations.

- Q: Why do rubber products become so long that they seem to melt and become sticky on the surface?

- If the solvent is tacky, the reason why the rubber is not involved in the crosslinking is dissolved. Rubber products are generally crosslinked, and the crosslinked part is the main part of rubber. It only swells and dissolves under the action of solvent. If this is the case, it will not stick when the solvent is dry.

- Q: What adhesive does rubber and wood have better glue?

- Early rubber was made from latex of rubber trees, rubber grass and other materials made of flexible, insulating, impermeable and air. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: What kind of rubber does TPE belong to?

- TPE does not belong to rubber.Although TPE has a tensile resilience similar to that of ordinary rubber, TPE is thermoplastic and rubber is thermosetting. Rubber needs cross-linking. It can not be reprocessed after molding. TPE can be processed repeatedly.

Send your message to us

DN125 Concrete Pump Pipeline Cleaning Ball

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords