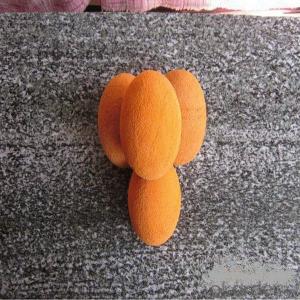

Zoomlion DN125 Concrete Pump Pipe Cleaning Ball

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Zoomlion DN125 Concrete Pump Pipe Cleaning Ball

SIZE

Cleaning Ball --- DN80, DN100, DN125, DN150

Cleaning Column --- DN125, DN150

STYLE

Cleaning Ball --- hard type, soft type

Cleaning Column --- hard type

FUNCTION

Its main function is used for cleaning concrete pipeline.

PACKING

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Feature

1. It is mainly used for cleaning all kinds of diameter of pump pipe cleaning tool,

maintenance of pipeline cleaning, made channel is more unblocked, unimpeded.

2. Greatly improving the work efficiency.

3. Prolong the service life of the various diameter pipe .

The main products

1. Concrete pump pipe :ST52 concrete pump pipe , 45Mn2 Wear resistant pipes, Twin wall pipes ,Reducer , tee, .ect.

2. the towed concrete pump, Concrete placing boom series.

3. Concrete pump truck fittings : Wear plate and wearring, Svalves, Concrete pump piston , delivery cylinder,.ect

4. Concrete pump clamp : DN80, DN100,DN125,DN150 Casting pipe clamp and Forged clamp.

5. Other accessories: Rubber hose , Cleaning ball , Sponge plug, Seal, The bearing seat, Flange etc.

- Q: How are rubber wires processed?

- [summary] the main raw material is rubber, rubber products with various agents, as well as the fiber and metal skeleton material, the basic production process of rubber products including plastication, mixing, calendering, extrusion, molding, curing 6 basic processes.The processing process of rubber is mainly to solve the process of plastic and elastic contradictions, through various means of processing, the elastic rubber has become the plastic rubber, adding various in the preparation of semi-finished products, and then through the vulcanization is has semi-finished plastic and rubber products into high elasticity and good mechanical performance the.

- Q: Silicone is silicone rubber? Extracted from there?

- Inorganic silica gel is a kind of highly active adsorbent material, which is usually reacted with sodium silicate and sulfuric acid, followed by a series of post treatment processes such as aging and acid foaming.

- Q: Why is natural rubber a strategic material?

- Rubber is an important strategic material, in the national defence application is very extensive, for example, a tank with more than 800 kg of general rubber; thirty thousand ton warship with sixty-eight tons of rubber, military equipment, air force facilities, almost all defense engineering rubber footprint. The use of rubber made ship, tent, warehouse and protective equipment, clothing etc. there are many varieties of bath water. As for the anti - tip technology needs high temperature, low temperature, oil resistance, high vacuum resistance and other special properties of the rubber, the constitution of 0 products is indispensable. With the development of national defense modernization, rubber, which is capable of resisting the temperature range of minus 100-400 DEG C and capable of resisting various acids, bases and oxidants with special properties, is being developed and manufactured.

- Q: What are the rubber parts for the car?

- Filter rubber parts, cloth (diaphragm), injection pump sealing ring, car frame sealing strip, door seal..... There are many, the car inside the big, small, a lot of rubber products. Watch more and you'll see.

- Q: How to solve the exhaust problem in rubber vulcanization process

- Rubber: the word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. The finished product is material with elasticity, insulation, waterproof and air

- Q: Can rubber products be injection molded and plastic injection functions?

- Rubber is an elastic polymer. Rubber can be obtained from the plant sap, can also be man-made, both have many applications and products, such as tires, washers, etc., has become an important economic crop. The cultivation of rubber is mainly concentrated in Southeast Asia, such as Thailand, Malaysia and Indonesia.

- Q: How to clean rubber products?

- Rubber products aging test belongs to the category of aging test, rubber aging refers to rubber and products in the processing, storage and use of the process, due to the comprehensive effect of internal and external factors caused by the performance of the structure change, then the loss of use value phenomenon. They are crazing, sticking, hardening, softening, powdering, discoloration, mildew, etc..

- Q: How can there be a crack in the rubber ring?

- In use, high temperature and exposure to sunlight in the air can cause aging and cracking of NBR

- Q: For the application of common synthetic rubber, not too long or too difficult, want to do

- Polybutadiene rubber (BR) is formed by polymerization of butadiene rubber CIS structure. The advantages are: flexibility and excellent abrasion resistance, good aging resistance, low temperature resistance is excellent in heat under dynamic load is small, easy to metal bonding. The disadvantage is low strength, tear resistance, processability and self-adhesive poor. Using temperature range: - 60 DEG C ~ + 100 DEG C. The general and natural rubber or butadiene rubber and tire tread, main production and transportation with cold and special products.

- Q: What are the causes of fracture in rubber products?

- Rubber products appear broken phenomenon, mainly for the following reasons:1, rubber products for a long time led to the phenomenon of fracture;2, too tired lead to rubber products broken;3, long-term exposure to ultraviolet light will cause rubber products broken;4, in the production of the use of chemical additives and materials conflict, resulting in incompatible and broken;5, the production process, the release of time is not appropriate, resulting in fracture (such as scratches);6, abrasive structure is irrational, lead to fracture;7, the use of materials is irrational, leading to fracture is also common;8, materials placed too long, in use, resulting in broken products, resulting in waste.

Send your message to us

Zoomlion DN125 Concrete Pump Pipe Cleaning Ball

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords