Aluminum Awning Sheets - Direct Deep Drawing Aluminium Circle AA3003 for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

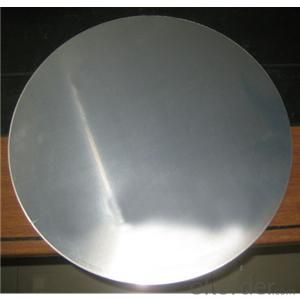

1.Structure of Direct Casting Aluminium Circle for Deep Drawing

Direc Casting Aluminium Circle for Deep Drawing is one semi-finished aluminium material. Aluminium Circle is widly used cookware, for example, aluminium pot, aluminium pan, aluminium cup ect. Our aluminium circle are widly exported to African market. We export more than 2000 tons every month. We can assure the breakage rate below 5%. Extra breakage will be responsible by our company.

2. Main features of Direct Casting Aluminium Circle for Deep Drawing

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Thickness | Diameter | Weight | Style |

| AA3003 | 0.2MM-2MM | 100MM-1000MM | 2 TONS | DEEP DRAWING |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 2 tons.

- Q: Describe the steps involved in installing aluminum sheets on a roof.

- <p>Installing aluminum sheets on a roof involves several key steps: 1) Inspect the roof structure to ensure it can support the new material. 2) Remove any existing roofing material. 3) Install roof underlayment to protect against moisture. 4) Position the first aluminum sheet at the lowest point of the roof, aligning it with the eaves. 5) Secure the sheet using clips or screws, ensuring a watertight seal. 6) Continue installing sheets up the roof, overlapping each by at least 2 inches for a secure fit. 7) Cut and fit sheets around vents, pipes, and other roof protrusions. 8) Install flashing and trim to finish edges and seal the roof. 9) Check for proper alignment and secure all fasteners. 10) Clean up debris and inspect the installation for any gaps or leaks.</p>

- Q: 1mm the aluminum plate is pulled to the height of 45mm. Can I pull it out at 1? How much space should I put in?

- How much clearance does aluminum plate stretch?The clearance value of the stretched aluminum plate is =1.3~1.4t (first stretch), 1.15~1.2t (second times stretch), and 1.1t (last stretch). The tensile properties of aluminum sheets are inferior to those of low carbon steel, and they are easily broken when stretched. The tensile height 45mm depends on the diameter of the drawing piece.A cylindrical part of a large cross-sectional area from a material to a small cross section is called a tensile coefficient. That is, the ratio of the cross-sectional area to the cross-sectional area before stretching, i.e., m=A0/An-1. For cylindrical parts, m1=d1/D0, the coefficient of the first stretch can be around 0.5, i.e., the diameter after the first stretch is 1/2 of the blank diameter before the drawing. In the future, the tensile coefficients are usually around 0.7~0.8. The calculation of drawing blank, roughly calculate the blank size according to the principle of equal area of the blank before and after the drawing.

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: What are the disadvantages of using aluminum sheets?

- Using aluminum sheets comes with several drawbacks. To begin with, aluminum is a relatively soft metal when compared to materials like steel. This softness makes it more susceptible to dents and scratches, which can negatively impact the sheet's overall appearance and structural integrity. Additionally, aluminum is a highly reactive metal, particularly in the presence of certain chemicals or harsh environments. This reactivity leads to corrosion, resulting in the formation of aluminum oxide, a white powdery substance. This corrosion weakens the sheet and compromises its durability. Furthermore, aluminum sheets are not as strong as steel sheets, rendering them less suitable for applications that demand high strength and stiffness. When dealing with heavy loads or extreme conditions, aluminum sheets may not provide the necessary structural support. Another disadvantage of aluminum sheets is their relatively high cost compared to other materials. The production process for aluminum involves energy-intensive steps, making it more expensive to manufacture. This cost can limit their use in projects with budget constraints. Moreover, aluminum sheets exhibit poor thermal and electrical conductivity when compared to metals like copper. This can be a disadvantage in applications where efficient heat transfer or electrical conductivity is required. Lastly, aluminum sheets have a lower melting point than steel, restricting their use in high-temperature applications. Subjecting aluminum sheets to high temperatures can cause them to weaken or deform, compromising their structural integrity. Overall, while aluminum sheets offer advantages such as being lightweight, corrosion-resistant, and versatile, they also come with several disadvantages that must be considered depending on the specific application.

- Q: What is the use?

- A series of 1000, representing the 1050106010701000 series aluminum is called pure aluminum, all in series 1000 series aluminum content belongs to one of the largest series. The purity can reach more than 99%. Because the technology does not contain other elements, the production process is relatively simple, the price is relatively cheap, is most commonly used in the conventional industry a a series of circulation on the market for most of the 1050 and 1060 series.1000 series aluminum plate to determine the minimum aluminum content in this series according to the amount of the last two Arabia figures, such as the 1050 series of the last two Arabia number 50, according to the international brand naming principles, content must reach to the top 99.5% qualified products. Aluminum Alloy technical standards China (gB/T3880-2006) is also clear that the aluminum content of 1050 aluminum content reached 99.5%. the same 1060 series aluminum must reach above 99.6%.The two and 2000 series aluminum 2A16 (LY16) 2A06 (LY6) features of 2000 series aluminum is high hardness, which belongs to the copper content is the highest, probably around 3-5%.2000 series aluminum plate belongs to aviation aluminum, currently in the conventional industries should not be used. Our current production of 2000 series aluminum manufacturers quality can not less. Compared with foreign countries. Currently imported aluminum is mainly provided by the production enterprises of South Korea and Germany. With the rapid development of China's aerospace industry, aluminum production technology of the 2000 series will be further improved.

- Q: Can aluminum sheets be anodized with custom colors?

- Yes, aluminum sheets can be anodized with custom colors. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum, and during this process, dyes can be applied to achieve a wide range of custom colors.

- Q: Are aluminum sheets suitable for cladding?

- Yes, aluminum sheets are suitable for cladding purposes. Aluminum is a popular choice for cladding due to its numerous advantages. Firstly, it is lightweight, making it easier to handle and install. This reduces the overall weight of the cladding system and minimizes structural load. Secondly, aluminum is highly durable and resistant to corrosion, making it suitable for both interior and exterior applications. It is also weather-resistant, ensuring that the cladding remains in good condition even in harsh climates. Additionally, aluminum is a highly versatile material that can be easily shaped and fabricated, allowing for a variety of design options. It can be painted or coated with various finishes to enhance its appearance and provide additional protection. Moreover, aluminum cladding is low maintenance, as it does not require frequent cleaning or painting. Overall, aluminum sheets are an excellent choice for cladding due to their lightweight, durability, versatility, and low maintenance requirements.

- Q: How much weight/people can a 12ft aluminum boat hold?and if anyone knows how much weight can a 6.5hp motor push around

- 12 Ft Aluminum Boats

- Q: How do you clean aluminum sheets?

- To clean aluminum sheets, you can start by rinsing them with water to remove any loose dirt or debris. Then, create a mixture of mild dish soap and warm water. Use a soft cloth or sponge to gently scrub the aluminum sheets with the soapy solution. Avoid using abrasive cleaners or scrub brushes, as they can scratch the surface of the sheets. Once you've thoroughly cleaned the sheets, rinse them again with water and dry them with a clean towel or cloth.

- Q: What's the difference between 6061 aluminum plate, 7075 aluminium plate and 6063 aluminum plate?

- 7075 T6 hardness in 150HB, hardness is highestUsually 6061 and 6063 can be common

Send your message to us

Aluminum Awning Sheets - Direct Deep Drawing Aluminium Circle AA3003 for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords