Perforated Honeycomb Direct Casting Aluminum Sheet for Color Prepainted Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

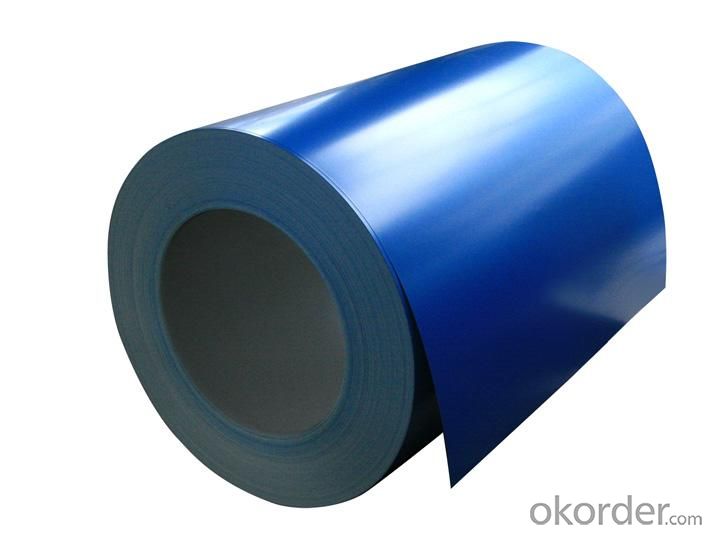

1.Structure of Direct Casting Aluminum Sheet for Color Prepainted Panel

Direct Casting Aluminum Sheet for Color Prepainted Panel is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Direct Casting Aluminum Sheet for Color Prepainted Panel

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | TEMPER | THICKNESS | COATING THICNESS | WEIGHT |

| AA3003 | H15 | 0.2MM-5MM | 22-25 MICRONS | 3TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are the aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are suitable for aerospace applications due to their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance, making them ideal for aircraft structures and components. Moreover, aluminum's ability to be easily machined, formed, and welded further enhances its suitability for aerospace use.

- Q: are there any carbonated mineral water that are produced in aluminium cans.

- Aluminium cans have an oxide covering on them so the reaction between them and the carbonated water is so little if any that it can't be noticed. Aluminium is also not so high on the reactivity series

- Q: Which is better, a water bottle made out of steel or one made out of aluminum?

- Aluminim is the way to go. I have an aluminum water bottle and so far it has been great. The bottle doesn't give the water any bad added flavor and it is lighter. Downside is that my water bottle has several dents in it but they just add character.

- Q: Can aluminum sheets be used in outdoor environments?

- Indeed, aluminum sheets are capable of being utilized in outdoor settings. Aluminum, a material that is both highly adaptable and enduring, proves to be a fitting choice for outdoor uses. Its exceptional resistance to corrosion renders it well-equipped to endure environmental factors like rain, snow, and UV radiation. Moreover, aluminum sheets are characterized by their lightweight nature and structural robustness, rendering them appropriate for a multitude of outdoor endeavors, including roofing, siding, and cladding. Furthermore, aluminum's non-combustible nature makes it a secure option for outdoor environments. All in all, aluminum sheets offer a dependable and enduring solution for outdoor applications.

- Q: How much is the aluminum plate with a thick 2mm 1000*2000? Thanks

- Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: Are 101 aluminum sheets suitable for outdoor applications?

- Yes, 101 aluminum sheets are suitable for outdoor applications. 101 aluminum is a popular alloy that offers excellent corrosion resistance, making it ideal for outdoor environments where exposure to moisture, sunlight, and other elements is common. Additionally, 101 aluminum has good strength and durability, allowing it to withstand various weather conditions and physical stress. It is often used in outdoor applications such as siding, roofing, gutters, and outdoor signage.

- Q: Is it possible to manufacture furniture using aluminum sheets?

- <p>Yes, aluminum sheets can be used to make furniture. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various furniture applications. It is commonly used in outdoor furniture, such as patio sets, as well as in modern indoor furniture designs. Aluminum furniture is easy to maintain, has a sleek appearance, and can be an eco-friendly choice due to its recyclability.</p>

- Q: What are the different types of finishes available for painted aluminum sheets?

- There are several types of finishes available for painted aluminum sheets, including matte, satin, glossy, metallic, and textured finishes. These finishes provide different levels of sheen, texture, and visual appeal, allowing for a wide range of aesthetic options for various applications.

- Q: Can 101 aluminum sheets be used in food storage containers?

- No, 101 aluminum sheets should not be used in food storage containers. Aluminum sheets, commonly known as 101 aluminum, are not food-grade materials. They are typically used in industrial applications such as roofing, construction, and electrical wiring. Food storage containers need to be made of food-grade materials that are safe for storing and preserving food. It is recommended to use containers made of stainless steel, glass, or food-grade plastic for food storage to ensure the safety and quality of the stored food.

- Q: what kind of aluminum sheet is suitable for aluminum alloy double-edged saw?

- general horizontal driving sawing and precision sawing.

Send your message to us

Perforated Honeycomb Direct Casting Aluminum Sheet for Color Prepainted Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords