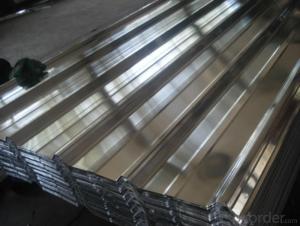

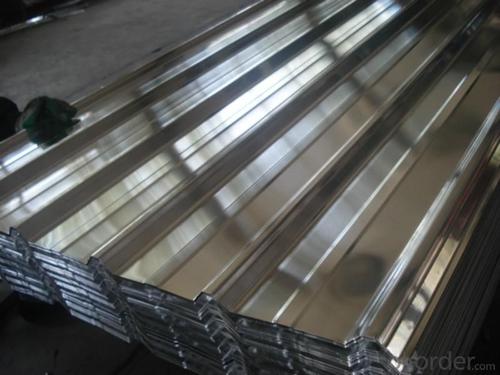

Aluminum Sheets Ace Hardware - Direct Casting Aluminum Plate in Different Corrugation Profiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Direct Casting Aluminum Plate in Different Corrugation Profiles

Specifications

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

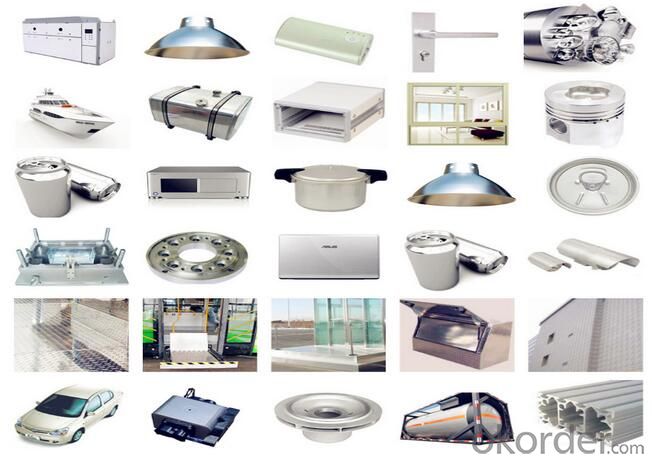

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

Packing

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q: Can aluminum sheet be painted?

- Certainly, painting aluminum sheet is possible. However, it is crucial to adequately prepare the surface beforehand to guarantee strong paint adhesion and long-lasting results. Typically, this involves thoroughly cleaning the aluminum sheet to eliminate any dirt, grease, or oxidation. Subsequently, a primer is applied to enhance adhesion. Once the primer has dried, you can proceed with applying your desired paint. For optimal outcomes, it is recommended to select a high-quality paint suitable for metal surfaces. Moreover, if the aluminum sheet will be exposed to outdoor conditions, it is advisable to utilize a paint specifically designed for exterior use. This will ensure protection against weathering and corrosion.

- Q: What are the different forming techniques for aluminum sheets?

- Aluminum sheets can be shaped using several different forming techniques. One technique commonly used is bending, where force is applied to the sheet to achieve the desired shape. This can be done manually with a press brake or through automated processes like roll forming or stretch forming. Another technique, called deep drawing, involves using a die and punch to stretch the aluminum sheet into a three-dimensional shape. This method is often employed to create cylindrical or box-shaped components such as cans or containers. Hydroforming is another option for shaping aluminum sheets. It utilizes hydraulic pressure to mold the sheet against a form or mold. This technique is particularly useful for creating complex and irregular shapes that would be challenging to achieve with other methods. For creating symmetrical shapes like bowls or cones, spinning is a commonly used technique. It entails rotating the aluminum sheet against a mandrel while applying pressure to shape it into the desired form. Lastly, there is a technique known as stamping, which involves pressing the aluminum sheet against a die to create a specific shape. This technique is frequently employed in high-volume production of components such as automotive body panels. In conclusion, these forming techniques provide a wide range of options for shaping aluminum sheets into various forms and designs. This allows for flexibility and versatility in manufacturing processes.

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Yes, aluminum sheets are suitable for use in HVAC systems. They offer several advantages such as high thermal conductivity, corrosion resistance, and lightweight nature, making them ideal for efficient heat transfer and durability in HVAC applications.

- Q: Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum, making it thicker and more durable. This process can be customized to achieve various finishes such as clear, colored, or even textured surfaces. The type of finish depends on factors like the alloy composition, anodizing method, and the desired appearance. Anodized aluminum sheets are widely used in various industries including architecture, automotive, and electronics due to their corrosion resistance, aesthetic appeal, and ability to retain color over time.

- Q: Maybe you didn't know but in the year 2025 the earth's population will be up to 12 billion people, which is double what we have now. And i am doing a project on Aluminum, and I have to know if there is enough AL for this many people in the year 2025. So will there be enough AL in the world to support us all?

- Aluminium is the third most abundant element on earth after oxygen and silicon. I am quite sure that we will not run out of aluminium in the future. Oxygen - or at least pure good quality oxygen - is probably a more worrying scenario.

- Q: why does 10% sulfuric acid not react with aluminum sheet?

- 10% sulfuric acid has a high concentration and will be passivated and formulate a layer of oxide film after reacting with aluminum,and the reaction will stop after seperating sulfuric acid and aluminum. there is a layer of Al2O3 oxide film on the surface of aluminum, so it's hard for sulfuric acid to break the oxide film and react with aluminum.

- Q: How is the coated aluminum mirror plate produced?

- Coated aluminum mirror as mean coated aluminum, aluminum mirror above the mirror effect is produced by the mirror, the mirror is in ordinary composite aluminum plate, the aluminum mirror cost will be relatively low. But the film of aluminum in the actual use of the process, must consider the problems of high temperature, because the mirror can not afford high temperature, easy to fall off, of course, as the most low-end series aluminum mirror inside a material, or he has a huge market range.And protect the protective coating of the material, whether it is coated with aluminum, or polished mirror aluminum, or other oxidation mirror aluminum, there will be.Interested in more understanding, you can search for "Ming Bao metal.""

- Q: What are the properties of anodized aluminum sheets?

- Anodized aluminum sheets have a protective oxide layer that provides increased corrosion resistance, durability, and a decorative finish. They are lightweight, non-toxic, and offer excellent heat and electrical conductivity. Additionally, anodized aluminum sheets are easy to clean, resistant to fading and scratching, and can be dyed in various colors for aesthetic purposes.

- Q: Can aluminum sheets be used for signage purposes?

- Indeed, signage purposes can be fulfilled by utilizing aluminum sheets. The signage industry often relies on aluminum, a highly adaptable and enduring material. Renowned for its lightweight nature, corrosion resistance, and exceptional weather resilience, aluminum is an ideal choice for both indoor and outdoor signage. By effortlessly cutting and molding aluminum sheets, one can fashion diverse sizes and designs for signs. These sheets can be painted, coated, or printed upon to exhibit logos, text, or graphics. Moreover, aluminum signs are economically advantageous and possess a prolonged lifespan, rendering them a favored option for businesses, construction sites, road signs, and various other signage applications.

- Q: How do aluminum sheets perform in terms of fatigue resistance?

- Aluminum sheets possess outstanding fatigue resistance, showcasing their ability to endure repeated stress and strain cycles without significant degradation in their mechanical properties. The exceptional fatigue resistance of aluminum sheets primarily stems from their microstructure, characterized by small and uniformly dispersed grains. This microstructure aids in the even distribution of applied stress throughout the material, effectively preventing crack formation and propagation. Moreover, fatigue resistance in aluminum sheets can be further enhanced through various processing techniques, such as heat treatment, alloying, and surface treatments. These techniques serve to refine the microstructure, enhance strength, and elevate the overall fatigue performance of the material. Furthermore, aluminum's relatively low density compared to other metals contributes to its superior fatigue resistance. This lower density enables improved energy absorption during cyclic loading, thereby reducing the likelihood of crack initiation and propagation. It is worth noting, however, that the fatigue resistance of aluminum sheets can vary depending on the specific alloy, temper, and thickness. Different aluminum alloys possess distinct mechanical properties and fatigue limits, necessitating the selection of the appropriate alloy and temper based on specific application requirements. In conclusion, aluminum sheets are highly esteemed for their remarkable fatigue resistance, making them a favored choice in industries that demand materials capable of enduring cyclic loading and extended service life.

Send your message to us

Aluminum Sheets Ace Hardware - Direct Casting Aluminum Plate in Different Corrugation Profiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords