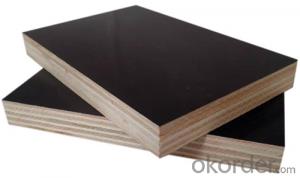

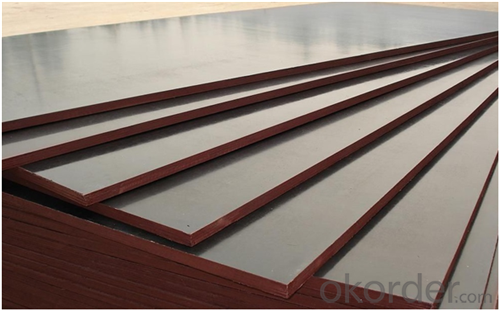

Different Color (Brown, Red or Black) Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywood

· Place of Origin: Shandong, China (Mainland)

· Model Number: film faced plywood

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E2, E0,E1,E2,

· Plywood Type: 9-Ply Boards

· Film faced plywood thickness: 18mm

· Moisture: 8~10%

· Species Core: Poplar, Combi, Hardwood, Birch

· Standard Size: 1220x2440mm,1250x2500mm

· Glue: Melamine WBP, Phenolic WBP,MR

· Film: Brown, Red, Black

· Cycle Life: about 6~10 repeated using times

Packaging & Delivery

Packaging Details: | film faced plywood Inner packing: Wrapped with 0.2mm plastic bag Outer packing: Pallets are covered with 2.0 mm plywood and then steel tape for strength. |

Delivery Detail: | within 15 days after order confirmed |

Product Description:

Film faced plywood is mainly made up of eucalyptus plywood, poplar plywood or eucalyptus and poplar plywood, it is economic and practical for the construction concrete pouring, for it could be the face panel for any formwork system, for example, steel frame formwork system, single side formwork system, timber beam formwork system, steel props formwork system, scaffolding formwork system, etc.

Product features:

1. Light Weight: We choose the high grade eucalyptus and poplar as the basic material, they are very light, so film faced plywood is convenient for transporting, and only one person could delivery single formwork by hand.

2. Easy To Cut: the plywood is easy to cut, so according to the construction, the formwork could be cut into the required size.

3. Re-used: Film faced plywood could be used 8-10 times.

4. Multi Using: Film faced plywood could be used for wall, slab, column, beam and bridge concrete pouring etc.

5. No Deformation: Film faced plywood is also whole but not deformation and chipping after 72 hours cooking in boiling water.

6. High Quality Film: It protect the formwork surface from the corrosion and makes the formwork durable, improves the flatness of the concrete surface and makes the concrete surface save the second time plastering, so it could save a lot cost of construction.

Product Specification:

Product Name | Film faced plywood | ||||

F/B | Black film, brown film, red film | ||||

Grade | Construction grade(one/two time hot press) | ||||

Core | Poplar, hardwood, birch, pine, combi , and so on | ||||

Glue | melamine and WBP | ||||

Thickness | 9-25mm | ||||

Specification | 1220x2440mm, 1250x2500mm,915x1830mm | ||||

Moisture Content | 8-10% | ||||

Package | Standard export packing | ||||

Press | one times press/two time press grade | ||||

MOQ | 1x20GP | ||||

Price Terms | FOB, CIF, CFR | ||||

Payment | T/T 30%, irrevocable LC | ||||

Delivery Time | Within 15 days after order confirmed | ||||

Supply Capacity | 4500 cbm/month | ||||

Usages | Can be widely used for building concrete, etc | ||||

Remarks | Top class equipment with top class produce technique; Credit first, fair trading | ||||

Formaldehyde Emission Standards | E2<30mg/100kg E1<9mg/100kg E0<5mg/100kg | ||||

Thickness(mm) | Layers | Standard size | Large size | ||

min. (mm) | max.(mm) | min.(mm) | max.(mm) | ||

9 | 7 | 8.5 | 9.5 | 8.2 | 9.5 |

12 | 8 | 11.5 | 12.5 | 11.2 | 12.5 |

15 | 9-10 | 14.5 | 15.5 | 14.2 | 15.5 |

18 | 11 | 17.5 | 18.5 | 17.2 | 18.5 |

21 | 13 | 20.2 | 21.5 | 20.2 | 21.5 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Housing ceiling with a good light or good sandwich panels

- Of course, light steel keel Well, first of all, wood keel easy to crack, deformation. Because the wood keel is not moisture, which easily lead to ceiling cracking, deformation, and easy to be corrosion, insects. In addition to the above problems, there are hidden dangers such as ceiling fall. Second, the wood keel strength and toughness is poor, resulting in the ceiling, partition wall life is short, and not fire, easily lead to fire. Light steel keel is a substitute for wood keel. Light steel keel with high strength, corrosion resistance, structural stability, easy to deformation and so on. Its flatness is better, the construction speed, good stability, as well as fire, moisture and other advantages, so, in order to renovate the dormant hidden, it is best to use light steel keel.

- Q: Tell us about the polyurethane sandwich panels, and how is its fireproof function?

- Polyurethane sandwich panel is a kind of new type of building material with hard foam polyurethane as sandwich material and color steel cover. It is by the pressure plate, polyurethane insulation materials, under pressure from the composition of the plate together. Polyurethane energy-saving board for the roof tilt of 3% of the class of industrial and commercial buildings, self-cleaning high-grade panel, reducing the amount of roof ash, so that the building roof to maintain long-term crystallization, high crest to improve the carrying capacity of the roof, Large, fast drainage, easy installation and other characteristics, lap at the use of fluid mechanics design to ensure the installation of fast, airtight, anti-capillary water seepage effect. Polyurethane insulation board has a good insulation, heat insulation, noise effects, and polyurethane does not help combustion, in line with fire safety, fire level can reach B level, very suitable for all types of industrial plants, civil construction and public buildings such as steel Bearing roofing.

- Q: What is the acceptance criteria for rock wool sandwich panels?

- 1) upper and lower surface: the use of galvanized color steel plate, the thickness of 0.4-0.8mm. According to the specific requirements of customers, can also be used galvanized steel or galvanized steel plate. The steel plate is first molded by a molding machine and is compounded with the rock wool factory. ? 2) Yanmian core material: the use of density of 120kg / m yan rock block staggered laying, the fiber perpendicular to the sandwich plate on the upper and lower surfaces, and close contact to enrich the sandwich panel of the entire vertical and horizontal. The combination of rock wool and rock wool and the upper and lower steel plates through the high-strength foaming agent to form a whole, sophisticated production process to ensure that the high-density rockwool insulation and metal plate between the inner wall can produce poles Strong adhesion, so that the rock wool sandwich panel has a very good stiffness. ? Wujiang City Linxue purification Choi Board Co., Ltd. is the China Electronics Society Clean Technology Branch members. Commitment to various types of purification decoration, clean air-conditioning works, hydropower engineering facilities supporting the design, installation, commissioning through-train service.

- Q: There is a comprehensive building, a two-story canteen, three-story activity room, the roof for the Caigang sandwich panel roof, the building fire rating for the two, the roof sandwich board design using polystyrene foam sandwich panels can?

- Can not. Polystyrene foam sandwich panels are mostly flammable and flammable, preferably flame retardant, and the burning properties of their materials do not meet the requirements of Grade II refractory grade buildings. Our province has been a few cases of Caigang sandwich panel roof fire cases, due to sandwich material led to the rapid expansion of fire.

- Q: Is the foam sandwich plate formaldehyde?

- Use to enjoy the formaldehyde detector under the test to know whether it contains formaldehyde, and large screen real-time display, triple alarm preset function, Portable compact hand.

- Q: What are the benefits of rock wool sandwich panels and what are the advantages?

- Shandong Yonggu Building Materials Co., Ltd. specializes in the production of rock wool sandwich panels, rock wool sandwich panels with fire, thermal insulation, sound-absorbing sound insulation, beautiful appearance, convenient construction, green and other excellent performance. Widely used in large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, activities room, building plus layer, clean workshop and the need to heat insulation fire places. ???? Hope to help you, if there is any doubt, look at our company's website, there are detailed details of the product, in search company name can be found, I wish you a good mood.

- Q: Sandwich panel wall design please help?

- Is this 127 square? 5.45 and 3.85 are two sides of the width of the original is a large, now divided into two large one small, long is 15 meters, in front of the board height is 3.27 meters. Followed by 2.87 on both sides of the wide plate height is 3.2 meters. So calculated out of 127 square feet

- Q: The main sheet of glass wool cotton sandwich panels

- Glass wool cotton sandwich panel panels made of colored steel plate, stainless steel plate, glass magnesium board three! The price of color steel plate is lower than that of stainless steel plate, so the price of stainless steel glass wool cotton sandwich panel is higher than that of Caigang glass wool cotton sandwich board! Double-sided color steel glass magnesium board as a panel of glass wool cotton sandwich panels need to do hand-made, so the cost of hand-woven glass wool sandwich panels is relatively high!

- Q: How to use the 0.3x50 sandwich panel to do a hundred square meters of roof to install how much money? Guanzhong area.

- With a color coated steel plate, rust does not solve the problem.

Send your message to us

Different Color (Brown, Red or Black) Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords