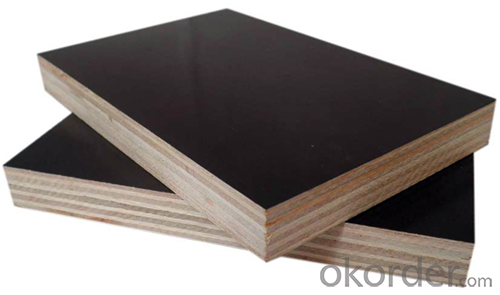

Brown Red and Black Color Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywood

· Place of Origin: Shandong, China (Mainland)

· Model Number: film faced plywood

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E2, E0,E1,E2,

· Plywood Type: 9-Ply Boards

· Film faced plywood thickness: 18mm

· Moisture: 8~10%

· Species Core: Poplar, Combi, Hardwood, Birch

· Standard Size: 1220x2440mm,1250x2500mm

· Glue: Melamine WBP, Phenolic WBP,MR

· Film: Brown, Red, Black

· Cycle Life: about 6~10 repeated using times

Packaging & Delivery

Packaging Details: | film faced plywood Inner packing: Wrapped with 0.2mm plastic bag Outer packing: Pallets are covered with 2.0 mm plywood and then steel tape for strength. |

Delivery Detail: | within 15 days after order confirmed |

Product Description:

Film faced plywood is mainly made up of eucalyptus plywood, poplar plywood or eucalyptus and poplar plywood, it is economic and practical for the construction concrete pouring, for it could be the face panel for any formwork system, for example, steel frame formwork system, single side formwork system, timber beam formwork system, steel props formwork system, scaffolding formwork system, etc.

Product features:

1. Light Weight: We choose the high grade eucalyptus and poplar as the basic material, they are very light, so film faced plywood is convenient for transporting, and only one person could delivery single formwork by hand.

2. Easy To Cut: the plywood is easy to cut, so according to the construction, the formwork could be cut into the required size.

3. Re-used: Film faced plywood could be used 8-10 times.

4. Multi Using: Film faced plywood could be used for wall, slab, column, beam and bridge concrete pouring etc.

5. No Deformation: Film faced plywood is also whole but not deformation and chipping after 72 hours cooking in boiling water.

6. High Quality Film: It protect the formwork surface from the corrosion and makes the formwork durable, improves the flatness of the concrete surface and makes the concrete surface save the second time plastering, so it could save a lot cost of construction.

Product Specification:

Product Name | Film faced plywood | ||||

F/B | Black film, brown film, red film | ||||

Grade | Construction grade(one/two time hot press) | ||||

Core | Poplar, hardwood, birch, pine, combi , and so on | ||||

Glue | melamine and WBP | ||||

Thickness | 9-25mm | ||||

Specification | 1220x2440mm, 1250x2500mm,915x1830mm | ||||

Moisture Content | 8-10% | ||||

Package | Standard export packing | ||||

Press | one times press/two time press grade | ||||

MOQ | 1x20GP | ||||

Price Terms | FOB, CIF, CFR | ||||

Payment | T/T 30%, irrevocable LC | ||||

Delivery Time | Within 15 days after order confirmed | ||||

Supply Capacity | 4500 cbm/month | ||||

Usages | Can be widely used for building concrete, etc | ||||

Remarks | Top class equipment with top class produce technique; Credit first, fair trading | ||||

Formaldehyde Emission Standards | E2<30mg/100kg E1<9mg/100kg E0<5mg/100kg | ||||

Thickness(mm) | Layers | Standard size | Large size | ||

min. (mm) | max.(mm) | min.(mm) | max.(mm) | ||

9 | 7 | 8.5 | 9.5 | 8.2 | 9.5 |

12 | 8 | 11.5 | 12.5 | 11.2 | 12.5 |

15 | 9-10 | 14.5 | 15.5 | 14.2 | 15.5 |

18 | 11 | 17.5 | 18.5 | 17.2 | 18.5 |

21 | 13 | 20.2 | 21.5 | 20.2 | 21.5 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Corrugated sandwich board is a kind of color steel plate? Thank you

- This is the difference between the sandwich panel and the color plate. These two are not the same thing, sandwich panels are 2 side color plate, the middle folder another layer of fire, insulation materials, such as extruded board or rock wool board, which is sandwich panels, in simple terms, sandwich panels Is a composite plate, while the color plate is only sandwich panels in the two composite materials in the surface plate. Not the same thing.

- Q: Fire protection recommendations for color steel sandwich panels

- Color plate can fire from six aspects: First, the use of good fire performance rock wool as a core material, which is a permanent solution. Second, in the process of building, the core material to stay away from welding, gas welding and other fire operations; Third, in the course of the use of some heat, the fire should not be next to the steel plate, to maintain a certain distance. If you want to set the kitchen in the color steel room, you need to have insulation layer, the wall should be installed fireproof rock insulation layer; Fourth, the wire, the cable is best not to pass from the core material, if necessary to wear protective cover Tube, socket, switch box should be used metal galvanized box and the use of mounted method; Fifth, indoor and outdoor with a simple fire fighting equipment, conditional installation of fire alarm should be convenient to facilitate the rapid evacuation of personnel; At least 6 meters to maintain a safe distance. Insulating materials that are not strictly flame-retardant are not flammable but are self-igniting. Strict, scientific and effective management, so that the fire away from the flammable color steel plate sandwich filler material, is to prevent color steel room fire is one of the important ways.

- Q: How is the ceiling of the residential sandwich panel under the roof?

- Method is to use the form of flat ceiling, the top of the pipeline blocked in the ceiling, the top can be embedded in the downlight or built-in fluorescent lamp, so that the top of the decoration after the formation of two levels, will not produce a sense of depression. Shaped ceiling with a cloud-like wave or irregular arc, generally not more than one-third of the overall top area, more or less than this ratio, it is difficult to achieve good results.

- Q: Sandwich board is 50,75,100,150, color steel thickness, casually one can.

- You do not know the thickness of the color plate is not the same as the core material is not the same as the thickness of the core material is not the same as you can say that

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides with the wall of the gap how waterproof ~

- If the gap with a small glass plug on it. If the gap is large, with a color plate to be a trough, riveting rivets and then use the glass glue to plug the gap

- Q: What is paper honeycomb sandwich panels

- Very simple two panels filled with honeycomb paper between the core layer!

- Q: Can Caigang sandwich panels cover cottage? Is it possible to install it?

- Can, need color steel sandwich panels to find Wujiang City, the LEADER air conditioning purification equipment engaged in color steel technology research and production, sales manufacturers

- Q: Ultrasonic cleaning machine cleaning Caigang sandwich panels the most basic quality conditions?

- The advantages of more professional cleaning machine work in the practice of the pursuit of a higher level of progress and development, improve the actual production efficiency of the guarantee, the most important thing is to really clean the product to achieve better cleaning results, to ensure greater advantages Cleaning conditions to achieve the purpose of cleaning, cleaning rate is the most important high-quality assurance.

- Q: I am in OKorder because of procurement needs, would like to first understand the color steel factory in OKorder which manufacturers quality and cheap products! Worthy of lazy thanks!

- OKorder Bo Xing color steel company specializing in the production of rock wool sandwich panels, fire, waterproof performance is very good, the supply of a lot of large steel company, you are welcome to call us, absolutely high quality and cheap

Send your message to us

Brown Red and Black Color Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords