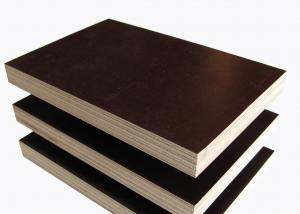

best shuttering plywood factory for film face plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of products Description:

Type:Plywoods

Place of Origin:Shandong, China (Mainland)

Brand Name:topwood

Usage:Outdoor

Grade:First-Class

Main Material:Poplar

Formaldehyde Emission Standards:E2

Plywood Type:12-Ply Boards

name:bamboo film faced plywood

key words:film faced plywood

basic feature: film faced plywood with high quality

Main Features of the products:

1) High bending strength

2 ) Little linear expansion conefficient

3) Strong nail holding

4) Moistureproof and easy work

5) Tight construction and high strength

6) No ratten or decay

7) Low formaldehyde emission

8) The produces are suitable for the construction of viaduct and tall frame buliding

9) If used abide by the illustration strictly, it can be reused more than 50 times.

Images:

Specification:

core:Poplar/birrch/hardwood/combi

Glue:MR/melamine/WBP

size: 1220mmx2440mm/610mmx2440mm/1250mmx2500mm

thickness:8mm/9mm/12mm/15mm/18mm/20mm or as requested

reuse:Above 12 times

modulus of repture:More than 30Mpa

modulus of eslticity:>=6000Mpa

- Q: Whether the rock wool sandwich panel is environmentally friendly

- How to say this, the board itself is environmentally friendly, the production process is not environmentally friendly ~

- Q: There is a comprehensive building, a two-story canteen, three-story activity room, the roof for the Caigang sandwich panel roof, the building fire rating for the two, the roof sandwich board design using polystyrene foam sandwich panels can?

- Can not. Polystyrene foam sandwich panels are mostly flammable and flammable, preferably flame retardant, and the burning properties of their materials do not meet the requirements of Grade II refractory grade buildings. Our province has been a few cases of Caigang sandwich panel roof fire cases, due to sandwich material led to the rapid expansion of fire.

- Q: Cold storage installation sandwich panels need to use sealant? With much more, with polyurethane sealant or silicone glue more?

- Generally with porcelain white neutral silicone

- Q: Color steel plate wall how many meters a general support, corrugated color plate non-sandwich panels

- Is there any angle between the top and bottom of the color plate? If not, the two panels at the junction should be set up a support point. If there is, 2-3 sets of color board can be set up to support, depending on the size of the project area average annual wind. We usually set up a 2 support.

- Q: 2x8 foor joists above not supporting the roof

- do you want to make a header for a 14 foot cased opening -- 2 boards of two inch by 12 inch wood are sufficient and you do not need any plywood in the center of the header ... if you are planning to panel and are adding a room type space then standing

- Q: The size of a standard sandwich panel is wide and wide

- Width is generally 1 meter, the length is not limited, because taking into account the transport, usually between the length of 3-18 meters. Sandwich is divided into polyurethane, rock wool, glass wool, polystyrene, and so on, the general thickness of 50mm.75mm.100mm, thicker can do.

- Q: What is the wall of the steel wire mesh in the building company? Is it easy to fix it again?

- Permanent wall is a new type of steel mesh sandwich panels, building without bricks, stay fast, low cost, Dongnuanxialiang, strong earthquake, energy saving, exclusive rural building materials, galvanized steel wire mesh Meet the use of functional and structural requirements of the space grid, the middle filled with molded polystyrene foam board or rock wool board and the formation of the board, in the Chinese industry standard specification referred to as CS board. CS board on both sides of the configuration of the longitudinal reinforcement, spray (wiping) concrete and the formation of the composite board wall, referred to as CS wall panels, that is, steel frame concrete composite panel wall. With fire insulation and anti-vibration can be secondary maintenance characteristics, far better than the effect of brick building.

- Q: What is the difference between the board and the core board? Usually where the place with sandwich panels where the use of laminates, such as the use of the shoe is the board, wardrobe with a sandwich panel? So what is the difference between the two

- Daxing board is made of two pieces of veneer stagnant stitching wood. Daxin board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending pressure The strength is more ... but the general is best not to choose! 2. Plywood, also known as plywood, some people called the carefully board. Three or more layers by 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm , 9mm, 12mm, ... Plywood Optional plywood is made of multi-layer veneer staggered arrangement of the sheet. The outermost front panel is called the panel, the reverse is called the back plate. Core board.

- Q: Sandwich panel wall design please help?

- In front of this wall is {(2.87 + 3.27) * 5.45} /2=16.73 The middle and the back of the algorithm are the same.

- Q: Color steel sandwich board board how to deal with bump

- After forming the basic no way, only to improve the process to solve

Send your message to us

best shuttering plywood factory for film face plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords