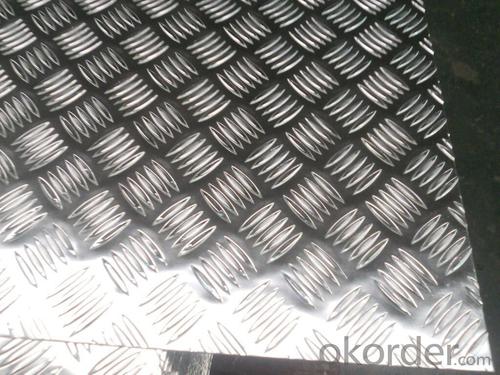

Diamond Plate Aluminum Sheets 1/16 - Coated Aluminium Coil AA1060-H16, 0.42mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

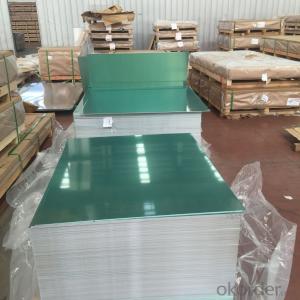

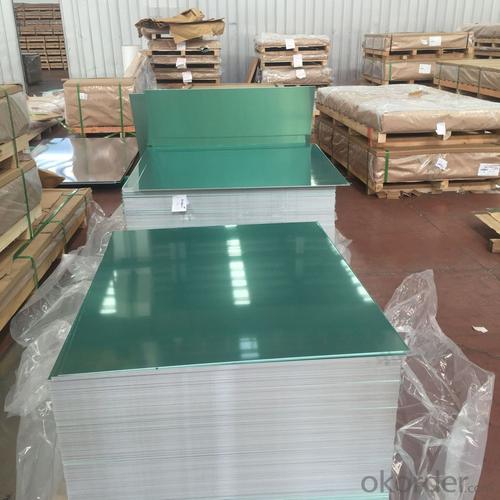

Aluminum coils color coated are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of the Aluminum Coils Colored Coated

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

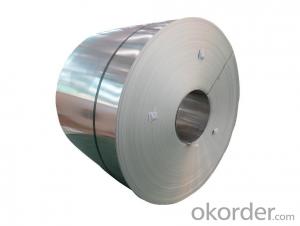

4.Aluminum Coils Colored Coated Specification

Alloy AA1xxx,AA3xxx,AA5xxx

Temper H14,H16,H18,H22,H24,H26,H32,O/F

Thickness 0.03mm-3.0mm

Width 30mm-1700mm

Coating PE,PVDF,Epoxy

Painting Thickness Standard 16-25 Mic, max 40 Mic

Color According to RAL colors or customers' samples

Standard GB/T 17748-1999

Characteristic:

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

- Q: I'm 17 and it has been very hard finding a deodorant that makes me stop sweating. I told my dad I wanted to get Ban or Mitchum cause the percentage of Aluminum is very high. He said the Aluminum in deodorant has links to alzheimers, is that true? Also my sister said I could just scrub with soap morning and night, use regular deodorant without antipersperant and that would make me stop sweating too. But since i'm a teenager and my hormones are still weird would that be strong enough to stop sweat?

- aluminum oxide in antipersperant does lead to alzheimer's, yes. but antiperspirant is not deodorant, and deodorant does not contain aluminum. sweating is a natural bodily function. if you need to sweat, sweat. it's odor that should bother people.

- Q: What is the most effective technique for applying a coating to aluminum sheets?

- <p>The best method for coating aluminum sheets depends on the desired application and properties of the coating. Common methods include anodizing, which provides a protective oxide layer, powder coating for a durable finish, and electroplating for enhanced corrosion resistance. For decorative purposes, methods like painting or vacuum deposition can be used. Each method has its advantages and is chosen based on factors such as cost, durability, and aesthetic requirements.</p>

- Q: I need to know what composite bats do and how (or if) they are better than aluminum bats.

- A okorder

- Q: Are aluminum sheets suitable for harsh weather conditions?

- Yes, aluminum sheets are highly suitable for harsh weather conditions. Aluminum is known for its exceptional corrosion resistance, making it highly durable and able to withstand extreme weather conditions such as heavy rains, snow, and strong winds. Additionally, aluminum sheets are lightweight yet robust, which allows them to resist damage from impacts or hailstorms. These properties make aluminum sheets a popular choice for outdoor applications, including roofing, cladding, and siding, as they provide long-lasting protection even in challenging weather environments.

- Q: Can the aluminum sheets be used for manufacturing audio amplifier cases?

- Yes, aluminum sheets can be used for manufacturing audio amplifier cases. Aluminum is a popular choice for casing in audio equipment due to its lightweight yet durable properties. It provides excellent heat dissipation, which is crucial for audio amplifiers that generate heat during operation. Furthermore, aluminum can be easily machined and formed into various shapes, allowing for customization and aesthetics in the design of the amplifier case. Overall, aluminum sheets are a suitable material for manufacturing audio amplifier cases.

- Q: What types of aluminum sheets are recommended for outdoor use due to their properties?

- <p>Yes, there are specific types of aluminum sheets designed for exterior applications. These include aluminum sheets with protective coatings such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a PVDF (Polyvinylidene Fluoride) coating, such as Kynar 500, are highly suitable for exterior use due to their excellent durability and resistance to UV rays, chemicals, and scratches. These coatings help maintain the aluminum's appearance and integrity over time, making them ideal for outdoor applications where exposure to the elements is a concern.</p>

- Q: We just bought a house with aluminum wiring and we knew about it in the inspection report, but everyone kept telling us it's no big deal. There was so much going on and I didn't look into it myself and now I just surfed the web on it and I am filled with anxiety! Please help! Did we make a huge mistake? How common are the dangers? Also, my insurance company didn't ask me about wiring, but some sites said that they don't cover aluminum wiring. Should I ask them? I am so overwhelmed and scared. I do not want a fire for my family!

- The aluminum is a soft metal and compresses and tends to loosen at the wire connections. It was probably installed properly with the semi compound and is probably ok. But the connections could be loose and cause a hot junction over heat in your service breaker box (Load Center). Every connection in the panel could be tightened a Quarter or half turn to snug them up by an electrician in just thirty minutes or so. and ease your concerns. Pay attention when he does and see if they turned or were still snug. this will give you insight into when to re check them a year or so down the line.

- Q: This question asks about the energy savings achieved by using aluminum sheets in comparison to other materials.

- <p>The energy savings achieved by using aluminum sheets instead of other materials can be significant. Aluminum is lightweight and has excellent thermal conductivity, which means it can reduce energy consumption in applications like building insulation and heat exchangers. For instance, aluminum-framed buildings can save up to 40% more energy than those made with traditional materials due to better insulation properties. Additionally, in industrial processes, aluminum's high thermal conductivity can lead to energy savings of around 33% compared to using copper in heat exchangers. The exact amount of energy saved depends on the specific application and the materials being replaced.</p>

- Q: Can aluminum sheets be used for insulation jackets?

- Yes, aluminum sheets can be used for insulation jackets. Aluminum has excellent thermal conductivity properties, which allows it to effectively reflect heat and prevent the transfer of thermal energy. This makes it an ideal material for insulation jackets, as it helps to maintain temperature control and minimize heat loss or gain. Additionally, aluminum sheets are lightweight, durable, and resistant to corrosion, making them a practical choice for insulation applications.

- Q: I'd like to have the aluminum on the etching front white. Do any of the experts know that?

- After anodizing, it turns white. If not, the aluminum plate should be white and spray polyester or fluorocarbon paint,

Send your message to us

Diamond Plate Aluminum Sheets 1/16 - Coated Aluminium Coil AA1060-H16, 0.42mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords