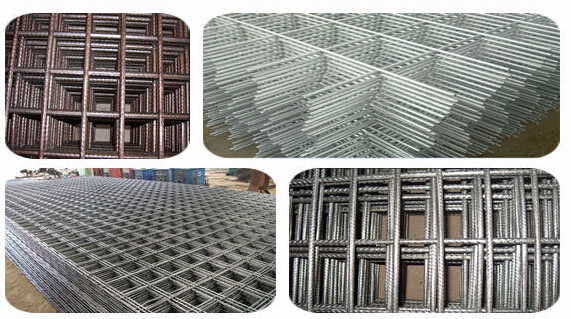

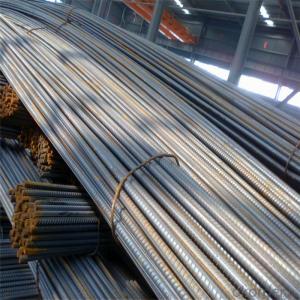

deformed steel bar welded wire mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

High Strength,Min 550MpaConvenient for installation

Cost effective

facilitating enhancement of project quality

Sreel Bar Welded Mesh

Tensile strength: 550Mpa min

Diameter:4mm-12mm

Application:construction

Model: A98, A142, A93, A252, A318, A475, A566 B196, B283, B385, B503, B636, B785, B1131 C283, C385, C503, C636, C785 D196, D283,D385, D503, D636, D785, D1131

| Mesh | Wire Dia. | Assortments available: |

| 1/4"X1/4" | BWG23 | Hot-dipped galvanized after welding; |

| 3/8"X3/8" | BWG19,20,21,22 | Hot-dipped galvanized before welding; |

| 1/2"X1/2" | BWG16,17,18,19,20,21,22,23,24 | Electro galvanized after welding; |

| 3/4"X3/4" | BWG16,17,18,19,20,21,22 | Electro galvanized before welding; |

| 1"X1/2" | BWG16,17,18,19 | Welded mesh, PVC-coated; |

| 1"X1" | BWG14,15,16,17,18,19,20,21 | Welded mesh made of stainless steel. |

| 1"X2" | BWG14,15,16 | |

| 2"X2" | BWG14,15,16,18 |

- Q: Hi i would like to ask what is the diference between the two versions of wiring the RJ 45 connector. when I was making my first networking cable, i used the wiring according to an image that only was using/connecting four wires into the connector. the cable works and works well. Now i found plenty of other images, all of them reccomending the full /eight wires/ connecting. Do I run my network on lower Mbits/sec? what are the other four wires used for? Thanks

- There Are Two Main Wiring Hook-ups That Should Both Work Just Fine.

- Q: ok, so i love making jewelry, and probably a year ago i went to michael's bought a roll-type thing of really soft, really, really thin silvery wire. a couple of days ago i went to michael's again and it wasn't there.as i said, the wire that i had is very thin, very soft, and also after you bend it, it won't snap back- it actually will never go back to being completely straight, even if you try to make it do that.is memory wire what i should be looking for?does anyone have any suggestions to what kind of wire i should get?

- Hi - I hope this information helps you - Beadalon? Remembrance? is thin, tempered stainless steel wire that is used as a beading medium. The wire is corrosion resistant and will resist tarnishing. Like a spring, Remembrance wire is rigid and snaps back to its original form when expanded and released. The wire remembers its shape and retains its coil form. Sterling Silver Wires To choose the right kind of silver wire for your project, you should know how you want the piece to look and what kind of piece you are creating. You will need to consider both the hardness of the wire and the gauge of the wire. There are three kinds of sterling silver wire. They are: Dead soft, half hard and full hard. Dead soft wire is very easy to bend. It can be better for wire wrapping or for making wire beads but will often not hold shapes intended for wire wrapping. Dead soft silver wire is usually used by people who work silver because it hardens as its shaped and hammered. Half hard sterling wire is stronger than dead soft but is still quite malleable. It is excellent in wire wrapping smaller or heavier beads and is a good choice for beading and jewelry making projects. Full hard silver wire is hard to use and bend and not necessarily recommended for jewelry making - at least for a hobbyist.

- Q: I'm cutting 18 gauge wire, so I can run valve wires to the timer in the garage. The plastic casing over the wire is pretty thick, so I had to squeeze hard. I accidentally cut into the color casing of the actual wire inside, so I want to start over. How can I cut this wire away, and start again?

- Take a utility knife and cut a 3/4 slot at the end of the cable parallel with the conductors. Use two pliers, one to hold the outer sheath, and one to grip the conductors. Pull them 180 degrees away from each other. When you have the stripped length you want, cut off the outer sheath where the wires are not inside. Any cutting around the circumference of the sheath while the wires are enclosed, will lead to cutting the insulation on the wires. This is why many manufacturers install a nylon zip cord inbetween the wires. You can grab it with one pliers and pull it away from the cable while holding the cable with the other pliers, to cut the outer sheath.

- Q: i changed the sprak plugs wires on my 1990 300e and when i put the car on Drive it vibrates strongly. i kept checking that each wire is in the right place and on. do i need to restart the brain or reprogram the car ?

- Sounds like if you are sure the wires are in the right place, you might have spiked the coil assy. I would buy a $7.00 spark tested and make sure all wires are sending spark to the plugs.

- Q: I m wondering if there s a Neutral Wire in this picture (yes I turned off the breaker to get this photo). I want to put in a quot;Smart Light Switchand they require a Neutral Wire. I ll have an electrician do the work, but want to make sure the wire exists first.

- It's hard to tell from the switch and the color of the wires, but you also have an outlet in the same box as the switch. The outlet will have a neutral and, if it's on the same circuit, you should be able to use that.

- Q: I'm just wondering would i be able to connect a split 8 gauge wire with wire nuts like i'll explain:Use two wire nuts instead of one and divide the copper wire on both ends and wire nut both sides together with 2 nuts. The whole apparatus would look kinda like this:----lt;gt;---- with the wire nuts connecting the two arrow thingsThanks anyone

- Even though you had been wise to make use of the noalox, or antioxidant, i might ratehr endorse that you get the suitable gauge of wire in copper and rewire the entire circuit. The intent that I say that's that your oven is a excessive resistance circuit and aluminum does no longer like high resistance. With excessive resistance on aluminum, the aluminum wire will start running or moving under the strain and can eventually burn out the connection. In the event you have got to leave it aluminum, don't use a wire nut, but get a split nut from an electrical provide, use teh same goop on it, then get two wrenches for the best way that you just ought to screw the break up bolt to the nut, tighten the item down as tight as humanly viable, the wrap it with a specified tape that the electrical give may also have. It's not the commonplace electrical tape, but a stretchable tape and also you wrap it tight at the least 3 or a bit of extra inches on all sides of the nut. This may insulate the connection in order that it are not able to be shorted out in any respect. Mine had the same aluminum connection and when I changed the stove, which was difficult wired to the stove, I simply replaced the entire wire. Mainly the field is just not too some distance away fromthe stove due to the fact it wants to be as just about it to decrease resistance. To scan what you have got performed, that you would be able to take a low-cost volt meter from Radio shack, set it on the correct settings for measuring voltage on 220, and if the needle goes to 220 + or - a bit, you're nice in the meanwhile.

- Q: Two steel wires are stretched with the same tension. The first wire has a diameter of 6.00E-4 m and the second wire has a diameter of 8.90E-4 m. If the speed of waves traveling along the first wire is 53.2 m/s, what is the speed of waves traveling along the second wire?

- Wave velocity v = √(T/μ) Same tension in both wires: T1 = T2 μ is the linear mass density v1 = 53.2 m/s v2 = ? = v1/v2 = √(T1/μ1) / √(T2/μ2) = √(T1μ2 / T2μ1) = √(T1/T2 * μ2/μ1) = √(μ2/μ1) Linear mass density is mass/length, mass is density*volume: m/L = ρV/L = ρAL/L = ρA = ρπr^2 Both wires are steel so their density is the same. == v1/v2 = √(μ2/μ1) = √(ρπr2^2 / ρπr1^2) = √(r2^2 / r1^2) = r2/r1 == v2 = v1r1/r2 = (53.2*3.00×10^-4) / 4.45×10^-4 = 35.9 m/s ---- Speed of waves along the second wire is 35.9 m/s

- Q: i have a 1995 chevy S10 blazer and i noticed that it has 5? speakers in the door and 6x9 in the back i started looking and i found that it has 4x6 in the dash with cardboard over it but it don't have speaker wire ran for it i think its going to be difficult running wire for it but what gauge of wire should i use? and should i run the speaker wire to the head unit how would i hook the speaker wire to the aftermarket head unit or should i run it to the 6x9 or 5? i already have a pair of 4x6's ready to be installed in it as soon as i find out how to do it and what size of speaker wire it is im going to be doing it by myself

- common speaker wire will work fine. as for running new wires to the dash. i have found that if you cut the hook off a metal coathanger and bend one end 6 inches from the end, you can tire the speaker wire to the bend and thread it thru. it just takes a little patience. i would wire them to the door speakers.

- Q: I have two kicker cvr 12s looking to wire them to an acoustic 601se amp can someone please tell me how to wire them like by matching the dots up and stuff.

- This Site Might Help You. RE: How to wire 2 12Kicker CVR 4ohm? I have two kicker cvr 12s looking to wire them to an acoustic 601se amp can someone please tell me how to wire them like by matching the dots up and stuff.

- Q: I NEED TO CHECK IF A WIRE IS GOOD ON A FITNESS MACHINE. HOW DO I KNOW IF ITS GOOD? WHAT SHOULD THE OHMS BE?

- Wire Ohms

Send your message to us

deformed steel bar welded wire mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords