Deformed Steel Bar HRB335 Construction Rebar

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product information:

| Commodity: | High quality hot rolled ribbed bar, Steel rebar, Deformed bars, Deform rebar |

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460B,GRB500B | |

| CAN/CSA-G30.18-M92 : 400W | |

| AS/NZS4671-2001 : GR300E, GR500E | |

| JIS G3112-2010 : SD345,SD390,SD490 | |

| ASTM A615 : Gr.40, Gr.60 | |

| DIN488-1984 : BST500 | |

| KS D 3504 : SD400 | |

| Diameter: | 6mm - 50mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

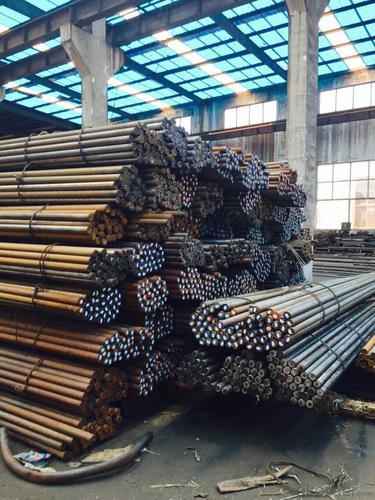

Product show

Workshop show

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

Screw steel is a steel bar with ribs on the surface, also known as ribbed bars, usually with 2 longitudinal ribs and transverse ribs evenly distributed along the longitudinal direction. The transverse rib shape is helical, herringbone, crescent 3. Nominal diameter of mm. Nominal diameter equal to the nominal diameter of the circular steel bars of equal cross section. The nominal diameter of the steel bar is 8-50 mm. The recommended diameter is 8, 12, 16, 20, 25, 32, 40 mm. Tensile stress in concrete with ribbed steel bars. Ribbed steel bar because of the role of ribs, and concrete have a larger bond capacity, and thus can better withstand the role of external forces. Ribbed steel bars are widely used in various building structures, especially large, heavy, light, thin wall and high rise building structures.

Thread steel is widely used in building, bridge, road and other civil engineering construction. Highways, railways, bridges, culverts, tunnels, flood control, dam etc. utilities to large, the small building foundation, beams, columns, a wall, a slab, rebar is indispensable structural materials.

This is the mechanical properties of thread steel grade and size specifications of the method.

H, R, B are hot rolling (Hotrolled), ribbed (Ribbed), steel (Bars) three words of the first letter in english.

HRB behind the figures, said its production level for the mechanical properties of materials, specific value is the material yield strength sigma S (sigma 91). Such as:

HRB335, which indicates that the yield strength is 335MPa of the rebar.

- Q: What are the different methods of surface honing for special steel?

- Surface honing for special steel can be achieved through various methods, each with its own benefits and uses. Among the commonly employed techniques are: 1. Manual Honing: This approach entails the utilization of handheld honing tools, such as stones, sticks, or abrasive pads, to manually remove material from the steel's surface. Manual honing permits meticulous control and is often suitable for smaller or intricate components. 2. Machine Honing: Machine honing involves the use of specialized honing machines that automate the honing process. These machines typically feature rotating honing stones or abrasive belts, which eliminate material from the steel's surface. Machine honing is favored for larger or complex parts, as it ensures consistent and high-quality outcomes. 3. Diamond Honing: Diamond honing relies on diamond abrasives to eradicate material from the special steel's surface. Given that diamond is one of the hardest substances known, it is exceptionally effective for honing steel. This method is commonly employed in high-precision applications or instances where an exceedingly smooth surface finish is required. 4. Superfinishing: Superfinishing is a specialized honing process that achieves extremely fine surface finishes on special steel. It combines honing stones and abrasive pastes to remove minuscule amounts of material from the surface. Superfinishing is typically utilized in critical applications where surface roughness and dimensional accuracy are of utmost importance. 5. Lapping: Lapping is a honing method that employs a combination of abrasive particles and a rotating or vibrating tool to eliminate material from the steel's surface. It is particularly suitable for parts necessitating a very flat or parallel surface, such as bearings or sealing surfaces. 6. Electrochemical Honing: Electrochemical honing is a specialized process that employs an electric current to remove material from the special steel's surface. It is often employed for intricate or hard-to-reach surfaces, as it effectively eliminates material from areas inaccessible to other honing methods. To sum up, the various methods of surface honing for special steel encompass manual honing, machine honing, diamond honing, superfinishing, lapping, and electrochemical honing. Each method offers distinct advantages and applications, enabling precise control and the attainment of desired surface finishes and dimensional accuracy for special steel components.

- Q: How does special steel contribute to the power generation machinery industry?

- Special steel plays a crucial role in the power generation machinery industry by contributing to the efficiency, reliability, and durability of power generation equipment. Firstly, special steel possesses exceptional mechanical properties, such as high strength, toughness, and temperature resistance. These properties make it ideal for manufacturing key components of power generation machinery, such as turbines, generators, and boilers. The superior strength and toughness of special steel enable these components to withstand high pressures, extreme temperatures, and harsh operating conditions, ensuring the safe and efficient operation of power plants. Moreover, special steel alloys can be specifically designed to resist corrosion, erosion, and wear, which are common challenges faced by power generation equipment. Corrosion can be caused by the chemical reactions between metals and the environment, while erosion and wear result from the high-speed flow of steam, water, or gases. By utilizing corrosion-resistant and wear-resistant special steel, power generation machinery can operate for longer periods without significant degradation, reducing maintenance requirements and downtime. Another significant contribution of special steel to the power generation machinery industry is its ability to retain magnetic properties at elevated temperatures. This property is crucial for electrical generators, as it ensures optimal performance and efficiency. Special steel with excellent magnetic properties enables generators to produce electricity with minimal energy losses due to heat, resulting in higher power output and reduced energy consumption. Furthermore, the design flexibility of special steel allows for the production of customized components, tailored to the specific requirements of different power generation technologies. For instance, in nuclear power plants, special steel alloys with high resistance to radiation and neutron embrittlement are used for the construction of reactor pressure vessels and other critical components. In renewable energy systems like wind turbines, special steel with superior fatigue resistance is utilized to withstand the cyclic loading experienced by turbine blades. In summary, special steel significantly contributes to the power generation machinery industry by enhancing the efficiency, reliability, and durability of power generation equipment. Its exceptional mechanical properties, corrosion resistance, wear resistance, magnetic properties, and design flexibility make it indispensable for manufacturing components that can withstand extreme conditions and ensure the continuous and efficient generation of electricity.

- Q: How does special steel perform in terms of corrosion resistance?

- Special steel has excellent corrosion resistance due to its high content of alloying elements, such as chromium, nickel, and molybdenum. These elements form a protective layer on the surface of the steel, preventing corrosive substances from reaching the underlying metal. Additionally, special steel can be further enhanced with surface treatments or coatings to enhance its resistance to corrosion in harsh environments.

- Q: How is special steel used in the manufacturing of machinery?

- Special steel is used in the manufacturing of machinery due to its unique properties and characteristics. It provides exceptional strength, durability, and resistance to wear and corrosion, making it suitable for critical components such as gears, shafts, bearings, and cutting tools. Special steel also allows for precise machining and shaping, enabling the production of complex machine parts. Overall, special steel enhances the performance and reliability of machinery, ensuring efficient and long-lasting operation.

- Q: How is spring steel used in the automotive industry?

- Spring steel is commonly used in the automotive industry for various purposes. It is primarily utilized to manufacture suspension systems, such as coil springs, leaf springs, and stabilizer bars. The unique properties of spring steel, including its high strength, elasticity, and resistance to deformation, allow these components to effectively absorb shocks and provide a smoother ride. Additionally, spring steel is also employed in the production of engine valves, seat frames, and steering components due to its durability and ability to withstand high temperatures and stress.

- Q: How does special steel contribute to improving product performance?

- Special steel contributes to improving product performance in several ways. Firstly, special steel has superior strength and durability compared to regular steel, making it more resistant to wear, corrosion, and impact. This increased durability ensures that products made with special steel have a longer lifespan and can withstand harsh conditions, ultimately enhancing their performance and reliability. Additionally, special steel can be tailored to have specific characteristics, such as high temperature resistance or magnetic properties, which can be crucial for certain applications. By using special steel, manufacturers can create products with enhanced functionality, efficiency, and safety, ultimately leading to improved overall performance.

- Q: How does special steel perform in terms of weldability?

- Special steel generally performs well in terms of weldability. It has good ductility and can be easily welded using various welding methods such as arc welding, resistance welding, and laser welding. The composition and properties of special steel are specifically designed to ensure that it can be successfully welded without compromising its strength and integrity. However, the specific weldability of special steel may vary depending on its exact composition and specific grade. It is always recommended to consult the manufacturer's guidelines and follow proper welding procedures to achieve the best results when working with special steel.

- Q: What are the advantages of using special steel in construction?

- There are several advantages of using special steel in construction. Firstly, special steel offers exceptional strength and durability, making it suitable for high-rise buildings, bridges, and other structures that require long-term stability. Additionally, special steel is resistant to corrosion, which enhances its lifespan and reduces maintenance costs. Furthermore, special steel can be fabricated into various shapes and sizes, allowing for flexible and efficient construction designs. Lastly, due to its recyclability, special steel is an environmentally friendly choice that promotes sustainability in the construction industry.

- Q: What are the properties of heat-resistant steel?

- Heat-resistant steel has several key properties that make it suitable for use in high-temperature environments. Firstly, it has a high melting point, allowing it to withstand extreme heat without deforming or melting. Additionally, it exhibits excellent strength and toughness at elevated temperatures, enabling it to maintain structural integrity under thermal stress. Heat-resistant steel also possesses good oxidation and corrosion resistance, preventing it from corroding or deteriorating when exposed to oxygen or other corrosive elements at high temperatures. Finally, it has low thermal expansion, ensuring dimensional stability even when subjected to significant temperature changes. Overall, the properties of heat-resistant steel make it a reliable choice for applications in industries such as aerospace, power generation, and petrochemicals, where it can endure and perform consistently under intense heat conditions.

- Q: What are the common challenges in forging special steel?

- Common challenges in forging special steel include achieving the desired grain structure, maintaining uniformity and consistency throughout the material, controlling the temperature during the forging process, preventing cracks and defects, and ensuring proper heat treatment for the desired mechanical properties.

Send your message to us

Deformed Steel Bar HRB335 Construction Rebar

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords